Preparation method of linear-chain starch-aliphatic acid compounds with different molecular weights

An amylose and fatty acid technology, applied in the field of biodegradable material preparation, can solve problems such as interfering with experimental results and complex methods, and achieve the effects of simple operation, mild conditions and avoiding residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

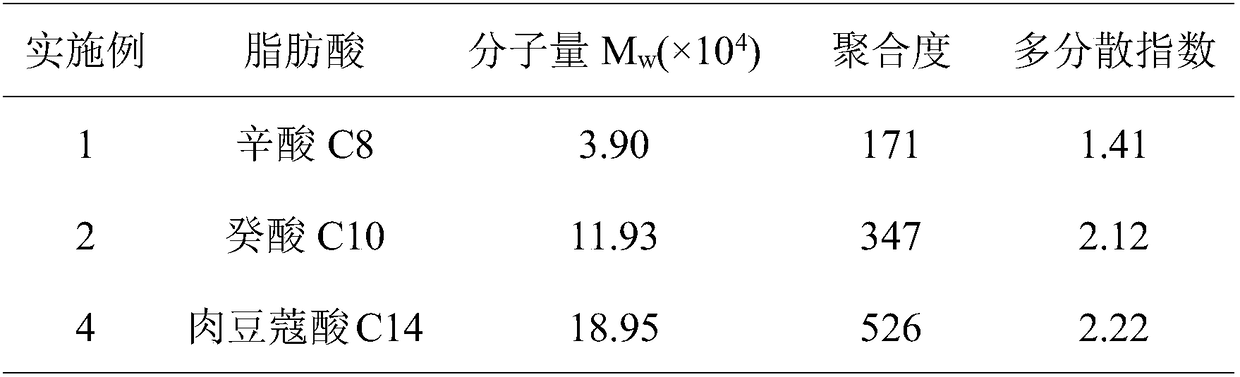

Examples

Embodiment 1

[0024] (1) Weigh 1g amylose (Mw is 200,000) into deionized water, prepare a 5% amylose suspension with mass fraction and put it into a polytetrafluoroethylene reactor, add 0.2g caprylic acid (C8), and mix it Seal, put the sealed reaction kettle in a ventilated oven and mix with vibration at 85°C for 1 hour;

[0025] (2) After vibrating and mixing, heat the suspension in the reaction kettle to 160°C, stop heating, and then stir the suspension to cool to 100°C. After cooling, place the reaction kettle filled with the suspension in a ventilated oven at 85°C. Rotate under heat preservation for 24 hours to obtain amylose-fatty acid complex;

[0026] (3) Dilute the amylose-fatty acid complex with water at 85°C to a mass fraction of 1%, centrifuge at 2000 rpm for 5 minutes, discard the supernatant, collect the precipitate, and wash it with 65°C hot water After 2 times, it was freeze-dried, and finally a white amylose-fatty acid complex powder was obtained.

Embodiment 2

[0028] (1) Weigh 1g amylose (Mw is 200,000) into deionized water, prepare a 5% amylose suspension with mass fraction and put it into a polytetrafluoroethylene reactor, add 0.2g capric acid (C10), and mix After sealing, place the sealed reaction kettle in a ventilated oven and vibrate and mix for 1 hour at 85°C;

[0029] (2) After vibrating and mixing, heat the suspension in the reaction kettle to 160°C, stop heating, and then stir the suspension to cool to 100°C. After cooling, place the reaction kettle filled with the suspension in a ventilated oven at 85°C. Rotate under heat preservation for 24 hours to obtain amylose-fatty acid complex;

[0030] (3) Dilute the amylose-fatty acid complex with water at 85°C to a mass fraction of 1%, centrifuge at 2000 rpm for 5 minutes, discard the supernatant, collect the precipitate, and wash with 70°C hot water After 2 times, it was freeze-dried, and finally a white amylose-fatty acid complex powder was obtained.

Embodiment 3

[0032] (1) Weigh 1g amylose (Mw is 200,000) into deionized water to prepare a 5% amylose suspension with mass fraction and put it into a polytetrafluoroethylene reactor, add 0.2g lauric acid (C12), and mix After sealing, place the sealed reaction kettle in a ventilated oven and vibrate and mix for 1 hour at 85°C;

[0033] (2) After vibrating and mixing, heat the suspension in the reaction kettle to 160°C, stop heating, and then stir the suspension to cool to 100°C. After cooling, place the reaction kettle filled with the suspension in a ventilated oven at 85°C. Rotate under heat preservation for 24 hours to obtain amylose-fatty acid complex;

[0034] (3) Dilute the amylose-fatty acid complex with water at 85°C to a mass fraction of 1%, centrifuge at 2000 rpm for 5 minutes, discard the supernatant, collect the precipitate, and wash with 70°C hot water After 2 times, it was freeze-dried, and finally a white amylose-fatty acid complex powder was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com