Lotus root processing slurry dehydration device

A dewatering device and slurry technology, applied in the field of lotus root processing slurry dewatering device, can solve the problems of starch extraction and shutdown, and achieve the effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following is further described in detail through specific implementation methods:

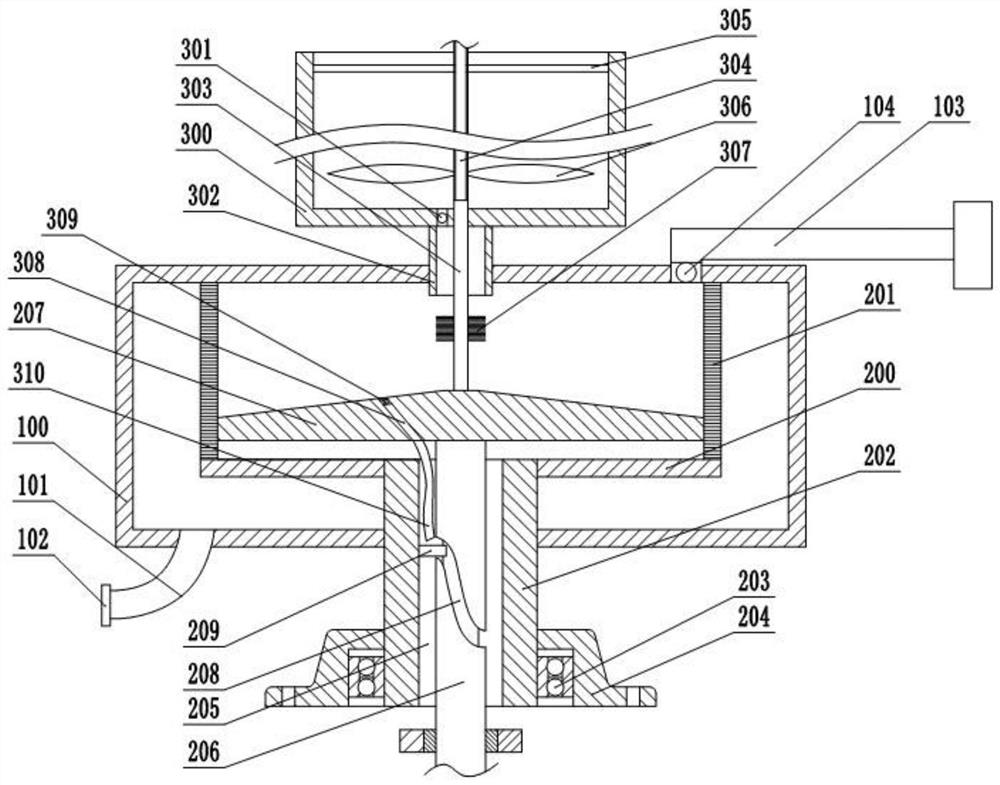

[0030] The reference signs in the accompanying drawings of the description include: water collection bucket 100, water outlet pipe 101, valve 102, discharge pipe 103, discharge one-way valve 104, dehydration bucket 200, filter hole 201, transmission shaft 202, ball bearing 203, bearing Seat 204, cavity 205, vertical rod 206, piston 207, curved groove 208, guide pin 209, feed barrel 300, feed check valve 301, feed pipe 302, push rod 303, rotating rod 304, cross bar 305, blade 306, hair brush 307, exhaust hole 308, air outlet check valve 309, flexible pipe 310.

[0031] Such as figure 1 Shown is the embodiment of the present invention, announced the lotus root processing slurry dehydration device, this device comprises frame, is fixedly provided with the water collecting bucket 100 of closed top on the frame, is provided with outlet pipe 101 at the bottom of water collecting bucket 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com