A kind of preparation method of fatty amine promoted by mechanical force

An aliphatic amine, nitrogen source technology, applied in the preparation of sulfuric acid amide, organic chemistry and other directions, to achieve the effects of green reaction conditions, high yield, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

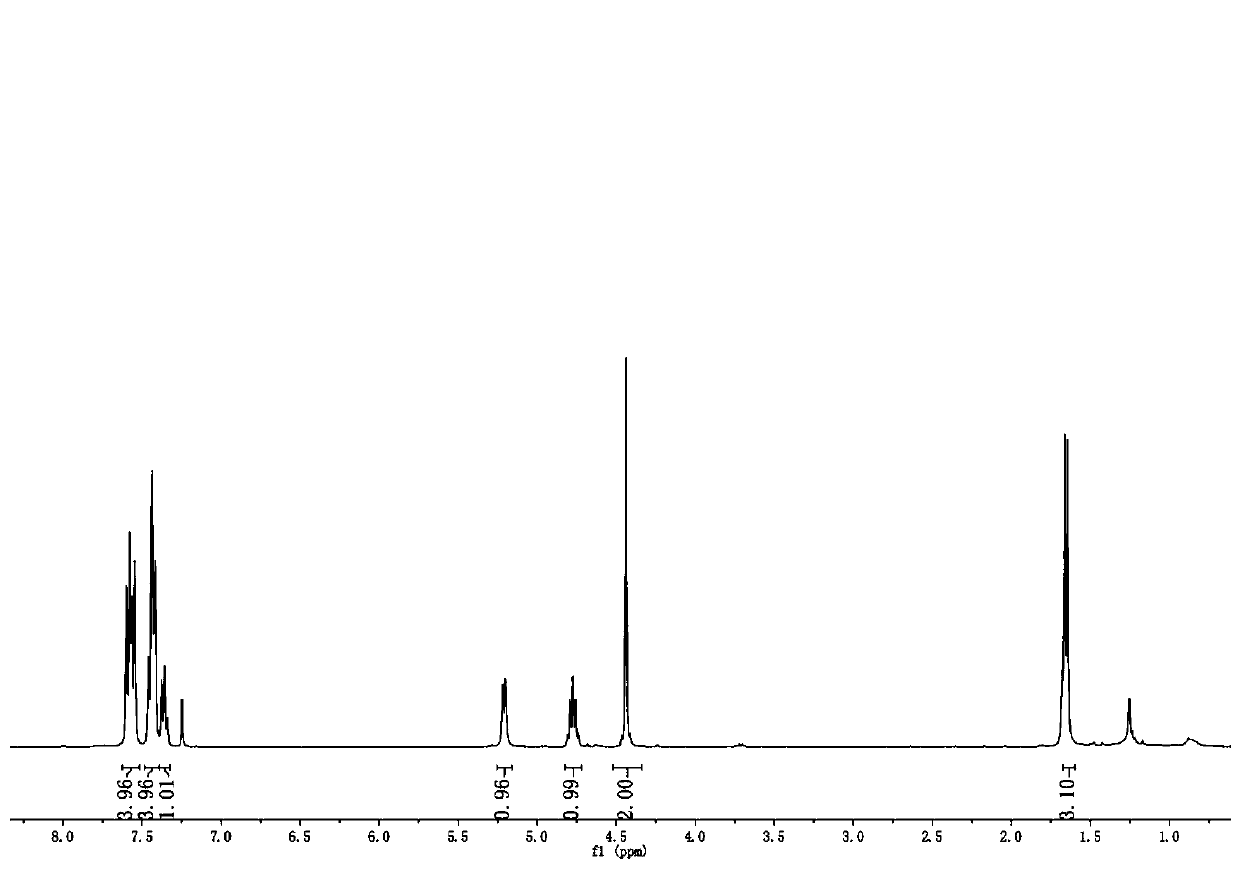

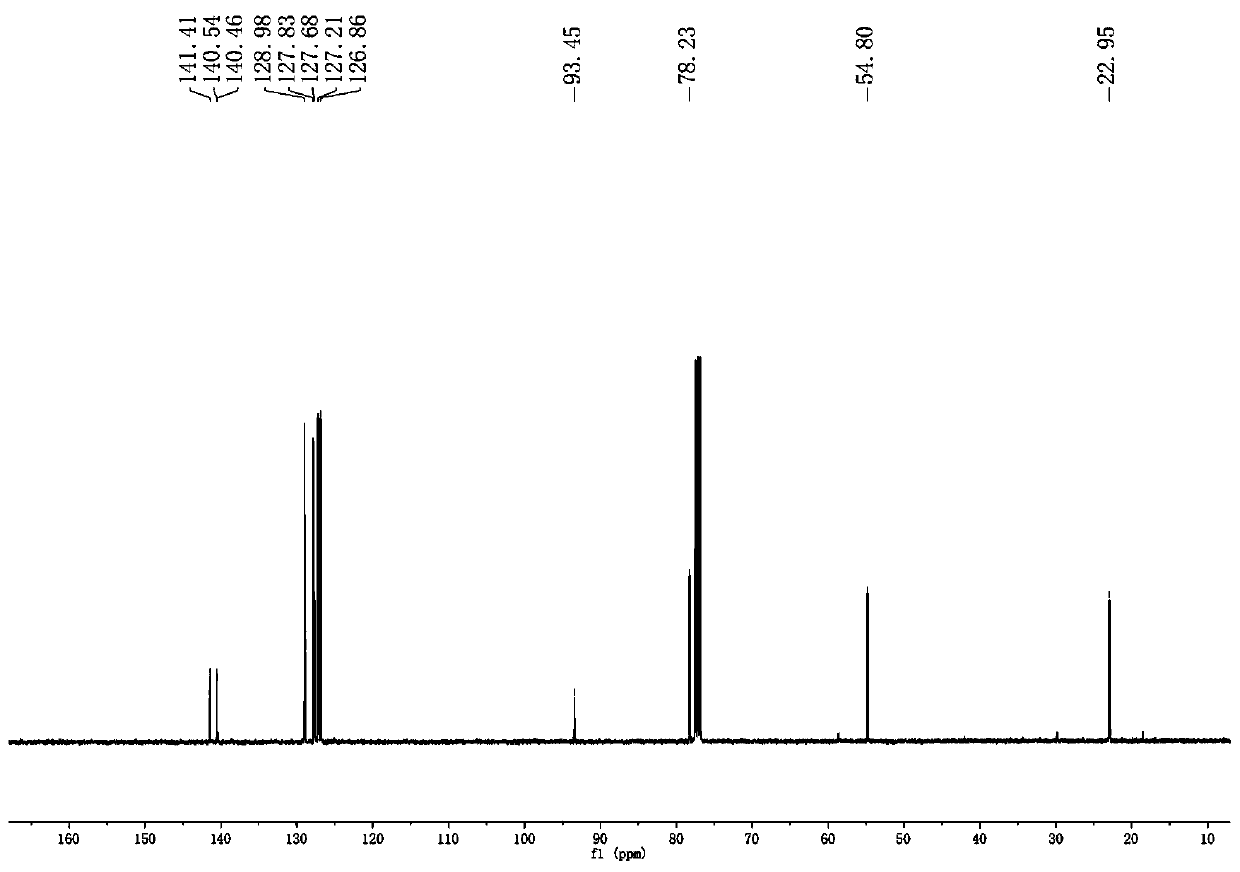

[0040] In a 50 ml stainless steel mortar and mortar, Rh 2 (esp) 2 (0.001mmol, 0.76mg), 4-ethylbiphenyl (0.3mmol, 54.7mg), 2,2,2-trichloroethylsulfamate (0.2mmol, 45.7mg), iodobenzene diacetate (0.4 mmol, 129 mg), NaHCO 3 (200mg). Put the stainless steel mortar in the ball mill After placing it safely, adjust the speed to 300r / min for 150min and start the machine. After the reaction is completed, lower the temperature to 25°C to 30°C, add dichloromethane to the reaction system, and wash thoroughly three times. The above dichloromethane solution was washed with water three times, the above dichloromethane phase was dried over anhydrous sodium sulfate, filtered and the dichloromethane was concentrated under reduced pressure to obtain a crude product. Use a 100-200-mesh silica gel column for separation, elute with a mixed solvent of petroleum ether / ethyl acetate (20:1), and collect the target product 2,2,2-trichloroethyl (1-([1,1' - biphenyl-4-yl) ethyl) sulfamate], and t...

Embodiment 2

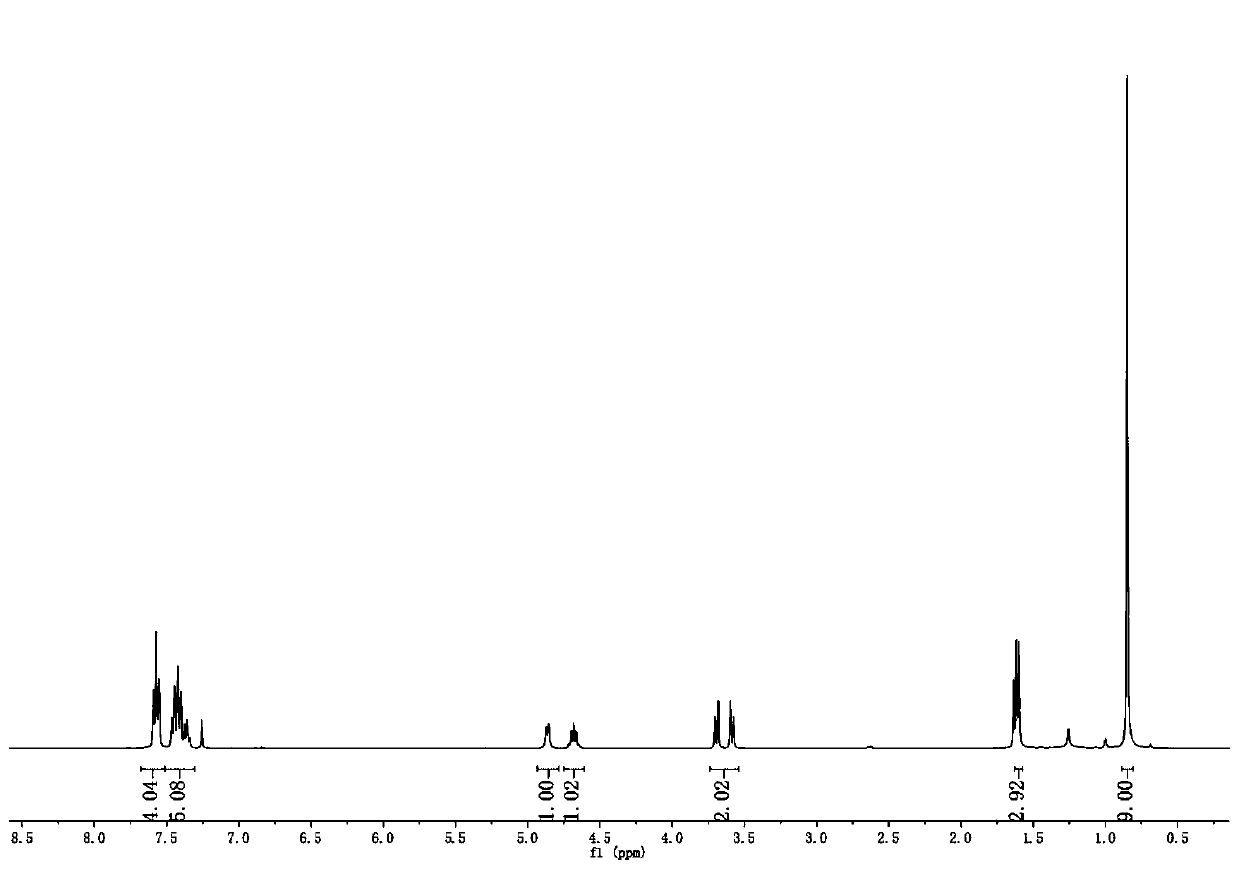

[0044] In a 50 ml stainless steel mortar and mortar, Rh 2 (esp) 2 (0.001mmol, 0.76mg), 4-ethylbiphenyl (0.3mmol, 54.7mg), neopentyl sulfamate (0.2mmol, 33.4mg), iodobenzene diacetate (0.4mmol, 129mg), NaHCO 3 (200mg). Put the stainless steel mortar in the ball mill After placing it safely, adjust the speed to 300r / min for 150min and start the machine. After the reaction is finished, lower the temperature to 25°C to 30°C, add dichloromethane to the reaction system, and wash thoroughly three times. The above dichloromethane solution was washed with water three times, the above dichloromethane phase was dried over anhydrous sodium sulfate, filtered and the dichloromethane was concentrated under reduced pressure to obtain a crude product. Use a 100-200-mesh silica gel column for separation, elute with a mixed solvent of petroleum ether / ethyl acetate (20:1), and collect the target product neopentyl (1-([1,1'-biphenyl-4- base) ethyl) sulfamate], and the organic phase was con...

Embodiment 3

[0048] In a 50 ml stainless steel mortar and mortar, Rh 2 (esp) 2 (0.001mmol, 0.76mg), 4-ethylbiphenyl (0.3mmol, 54.7mg), 4-nitrophenylsulfamate (0.2mmol, 43.6mg), iodobenzene diacetate (0.4mmol, 129mg) , NaHCO 3 (200mg). Put the stainless steel mortar in the ball mill After placing it safely, adjust the speed to 300r / min for 150min and start the machine. After the reaction is completed, lower the temperature to 25°C to 30°C, add dichloromethane to the reaction system, and wash thoroughly three times. The above dichloromethane solution was washed with water three times, the above dichloromethane phase was dried over anhydrous sodium sulfate, filtered and the dichloromethane was concentrated under reduced pressure to obtain a crude product. Use a 100-200-mesh silica gel column for separation, elute with a mixed solvent of petroleum ether / ethyl acetate (25:1), and collect the target product 4-nitrophenyl (1-([1,1'-biphenyl -4-yl) ethyl) sulfamate], and the organic phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com