A kind of building plate and preparation method thereof

A technology of building boards and main bodies, which is applied in the direction of buildings, building components, building structures, etc., can solve the problems of lack of crack resistance, compression resistance and bending resistance of building boards, so as to improve the compression resistance effect, improve fission resistance, increase The effect of unity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A building board with good pressure bearing effect, the building board includes a board body, and the body includes a main body filling part. The ingredients of the filling part of the main body and the parts by weight of various ingredients include but are not limited to the following formulations.

[0043] ① 25 parts of zeolite, 80 parts of quartz sand, 20 parts of bentonite, 15 parts of phenolic resin, 8 parts of epoxy resin, 15 parts of urea-formaldehyde resin, 8 parts of polyvinyl chloride, 2 parts of bicyclic amidine, 1 part of diethylenetriamine, ortho 1 part of phthalic anhydride, 0.5 parts of blowing agent, 0.5 parts of Si, 0.05 parts of Ti, 0.3 parts of Cr, 0.5 parts of fiber, 15 parts of calcium oxide, 3 parts of magnesium sulfate and 400 parts of water; ② 50 parts of zeolite, quartz 50 parts of sand, 40 parts of bentonite, 8 parts of phenolic resin, 15 parts of epoxy resin, 8 parts of urea-formaldehyde resin, 15 parts of polyvinyl chloride, 0.5 part of bicyc...

Embodiment 2

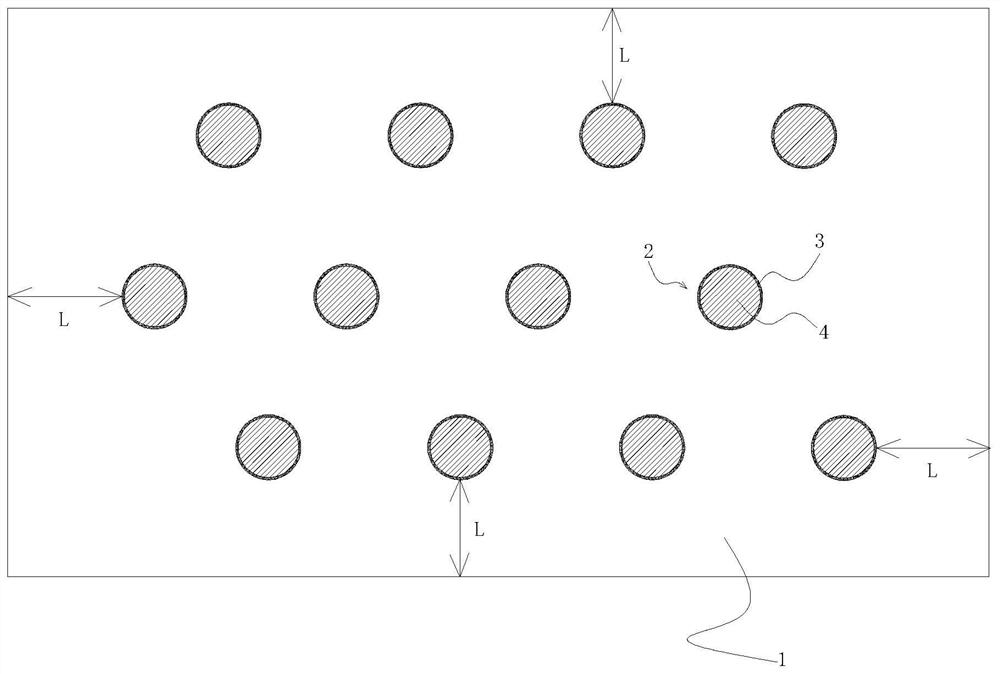

[0051] On the basis of Example 1, such as figure 1 As shown, the filling part of the main body is provided with a plurality of auxiliary holes evenly passing through the upper and lower end surfaces of the filling part of the main body. The auxiliary hole is provided with a spiral tube composed of a plurality of helical coils. The spiral tube There is a gap between two adjacent spiral coils, such as 1mm, etc., and the spiral tube is filled with auxiliary filler; the design of the gap between the spiral tube and the spiral coil makes the integration of the auxiliary filler and the main filling part better , so as to indirectly improve the pressure bearing effect and fission resistance of the entire building board.

[0052] The components of the auxiliary filler and the parts by weight of various components are as follows: 20-30 parts of phenolic resin, 1-2 parts of foaming agent, 3-8 parts of fiber, 10-15 parts of calcium oxide and 15-15 parts of water. 50 parts, preferably, 2...

Embodiment 3

[0055] On the basis of Example 2, the spiral tube is a spiral tube made of shape memory alloy and containing multiple helical coils. Its materials such as Au-Cd, Cu-Zn, Cu-Zn-Al, Cu-Zn-Sn, Cu-Zn-Si, Cu-Sn, Cu-Zn-Ga, In-Ti, Au-Cu-Zn, NiAl , Fe-Pt, Ti-Ni, Ti-Ni-Pd, Ti-Nb, U-Nb and Fe-Mn-Si and so on.

[0056] Even though the helical tube has a diameter D at low temperature T1 小 memory, the diameter is D at room temperature T2 大 memory, and D 大 greater than D 小 ; At T1, the spiral tube can be placed in the auxiliary hole, and then the temperature is raised to normal temperature. At T2, the diameter of the spiral tube will increase due to its shape memory property, and the bonding strength with the filling part of the main body will be increased. Formability and fission resistance of building panels can be significantly improved by progressively pressing when not fully formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com