Aperture-controllable porous graphene nanometer material preparation method

A technology of porous graphene and nanomaterials, applied in graphene, nanocarbon, chemical instruments and methods, etc., can solve the problems of template material residue, high cost energy consumption, difficult to control pore size, etc., to improve utilization efficiency and reduce production. Cost, effect of high charge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

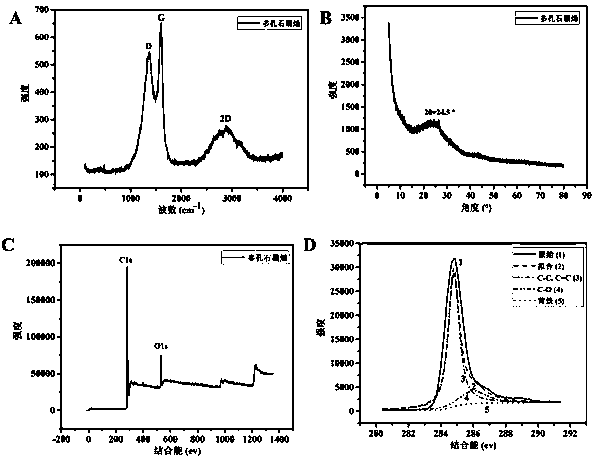

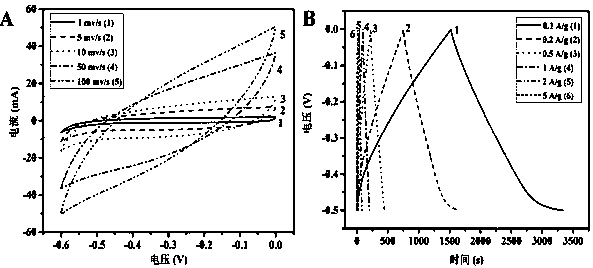

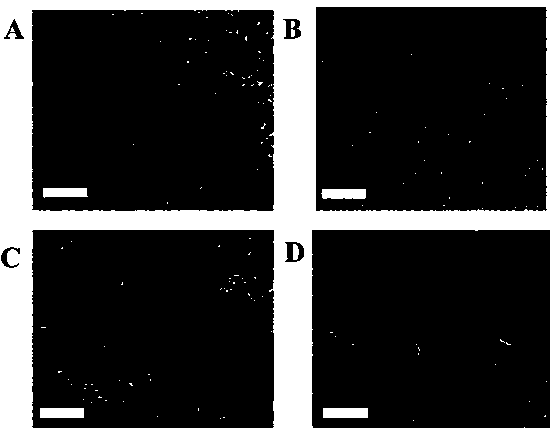

[0021] Example 1, Combustion under different time conditions prepares porous graphene nanomaterials

[0022] (1) Prepare 200 mL of 5 g / L graphene oxide suspension, and ultrasonicate at room temperature for 3 h for later use;

[0023] (2) Weigh 1 g of zinc nitrate, add 3 mL of water to dissolve it, add 1 mL of 5 g / L graphene oxide suspension, mix and sonicate for 10 min;

[0024] (3) Suction filter the mixed solution in step (2) onto quantitative filter paper using a Buchner funnel;

[0025] (4) Put the filter paper loaded with graphene oxide and zinc nitrate into an oven to dry at 60°C;

[0026] (5) Set the temperature of the muffle furnace to 400°C, 450°C, 500°C, and 550°C respectively. After the furnace temperature rises to the set temperature, put the dried filter paper into the muffle furnace and burn it for 1 minute before taking it out. product;

[0027] (6) Wash the burned product with hydrochloric acid to remove zinc oxide, and then wash with distilled water to remo...

Embodiment 2

[0031] Embodiment 2, combustion preparation porous graphene nanomaterial under different time conditions

[0032] (1) Prepare 200 mL of 5 g / L graphene oxide suspension, and ultrasonicate at room temperature for 3 h for later use;

[0033] (2) Weigh 1 g of zinc nitrate, add 3 mL of water to dissolve it, add 1 mL of 5 g / L graphene oxide suspension, mix and sonicate for 10 min;

[0034] (3) Suction filter the mixed solution in step (2) onto quantitative filter paper using a Buchner funnel;

[0035] (4) Put the filter paper loaded with graphene oxide and zinc nitrate into an oven to dry at 60°C;

[0036] (5) Set the temperature of the muffle furnace to 450 °C. After the furnace temperature rises to the set temperature, put the dried filter paper into the muffle furnace, burn for 1 min and 10 min respectively, and then take out the product;

[0037] (6) Wash the burned product with hydrochloric acid to remove zinc oxide, and then wash with distilled water to remove hydrochloric a...

Embodiment 3

[0039] Example 3, preparation of porous graphene nanomaterials under different mass ratios of graphene and zinc nitrate

[0040] (1) Prepare 200 mL of 5 g / L graphene oxide suspension, and ultrasonicate at room temperature for 3 h for later use;

[0041] (2) Weigh 1 g, 3 g, and 6 g of zinc nitrate (corresponding to graphene:zinc nitrate mass ratios of 1:200, 1:600, and 1:1200, respectively), add 3 mL of water to dissolve, and add to Add 1 mL of 5 g / L graphene oxide suspension, mix and sonicate for 10 min;

[0042] (3) Use a Buchner funnel to suction filter the mixed solution in step (2) onto quantitative filter paper;

[0043] (4) Put the filter paper loaded with graphene oxide and zinc nitrate into an oven to dry at 60°C;

[0044] (5) Set the temperature of the muffle furnace to 450°C. After the furnace temperature rises to the set temperature, put the dried filter paper into the muffle furnace, burn for 1 min, and take out the product;

[0045] (6) Wash the burned product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com