Three-way rotating shaft structure based on modularization

A rotating shaft, modular technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of not being able to guarantee the modularity of the rotating shaft structure, difficult to meet the modular product modeling, difficult to rotate and adjust, etc. The effect of high modularity and promotion value, ingenious structural design, and high modularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

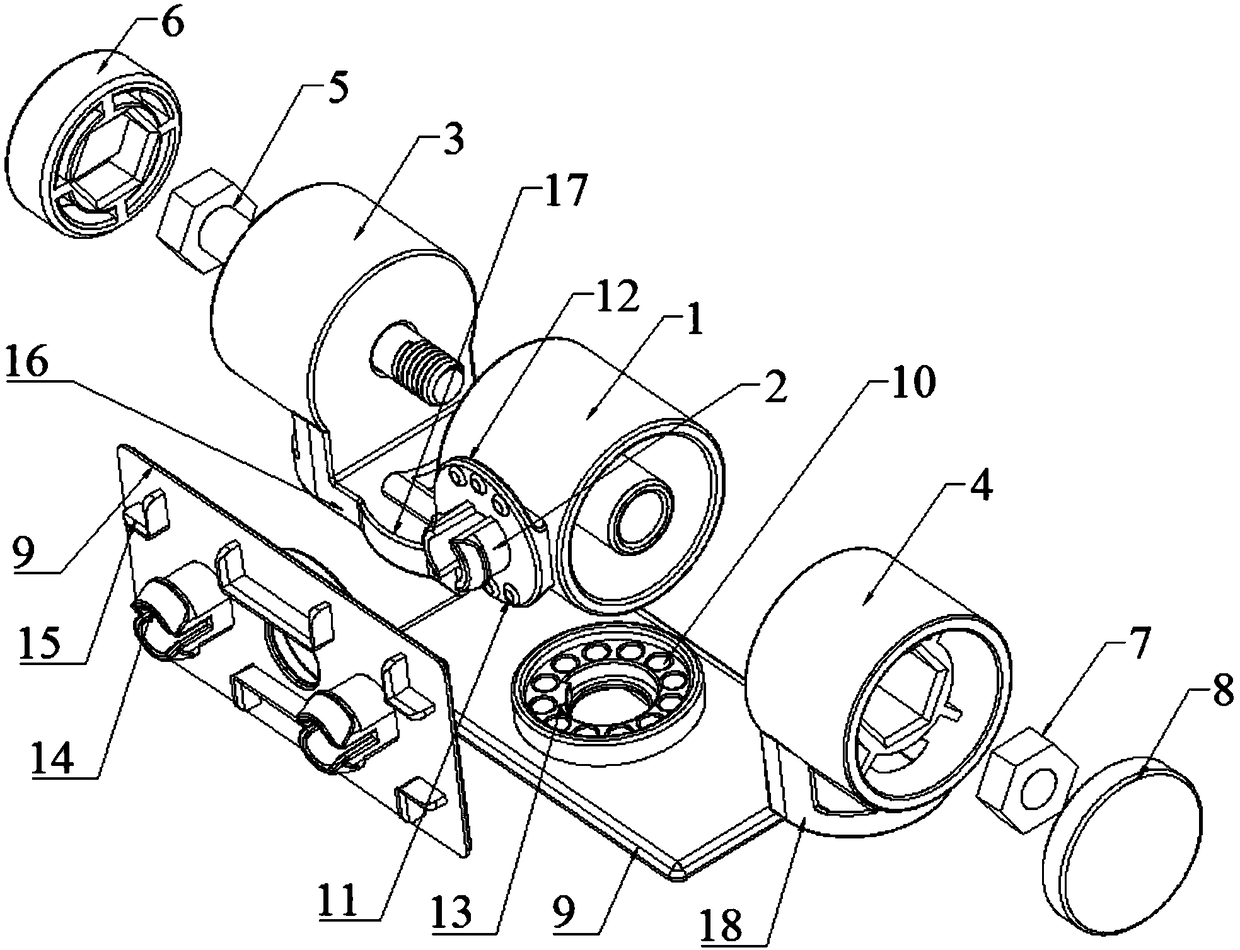

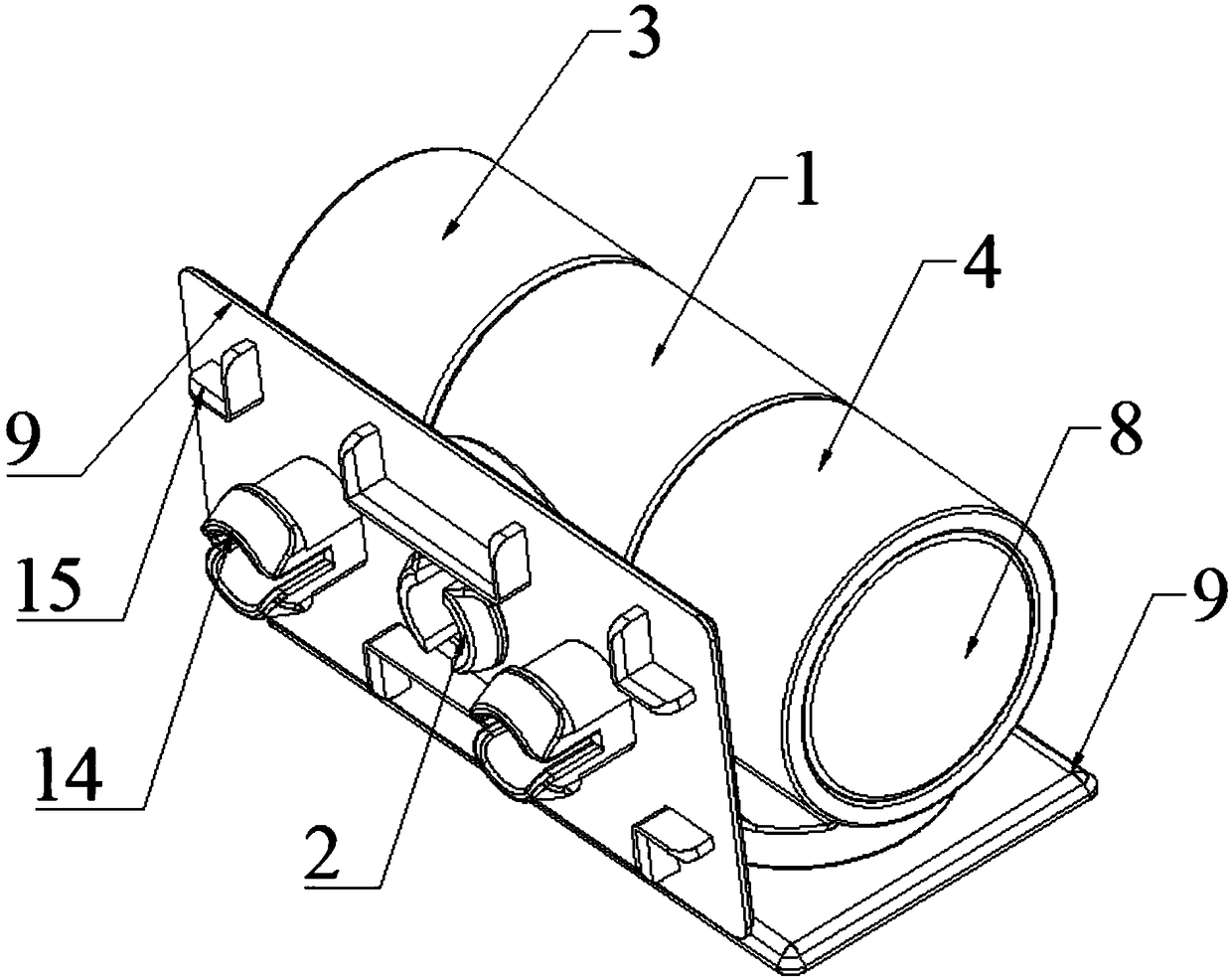

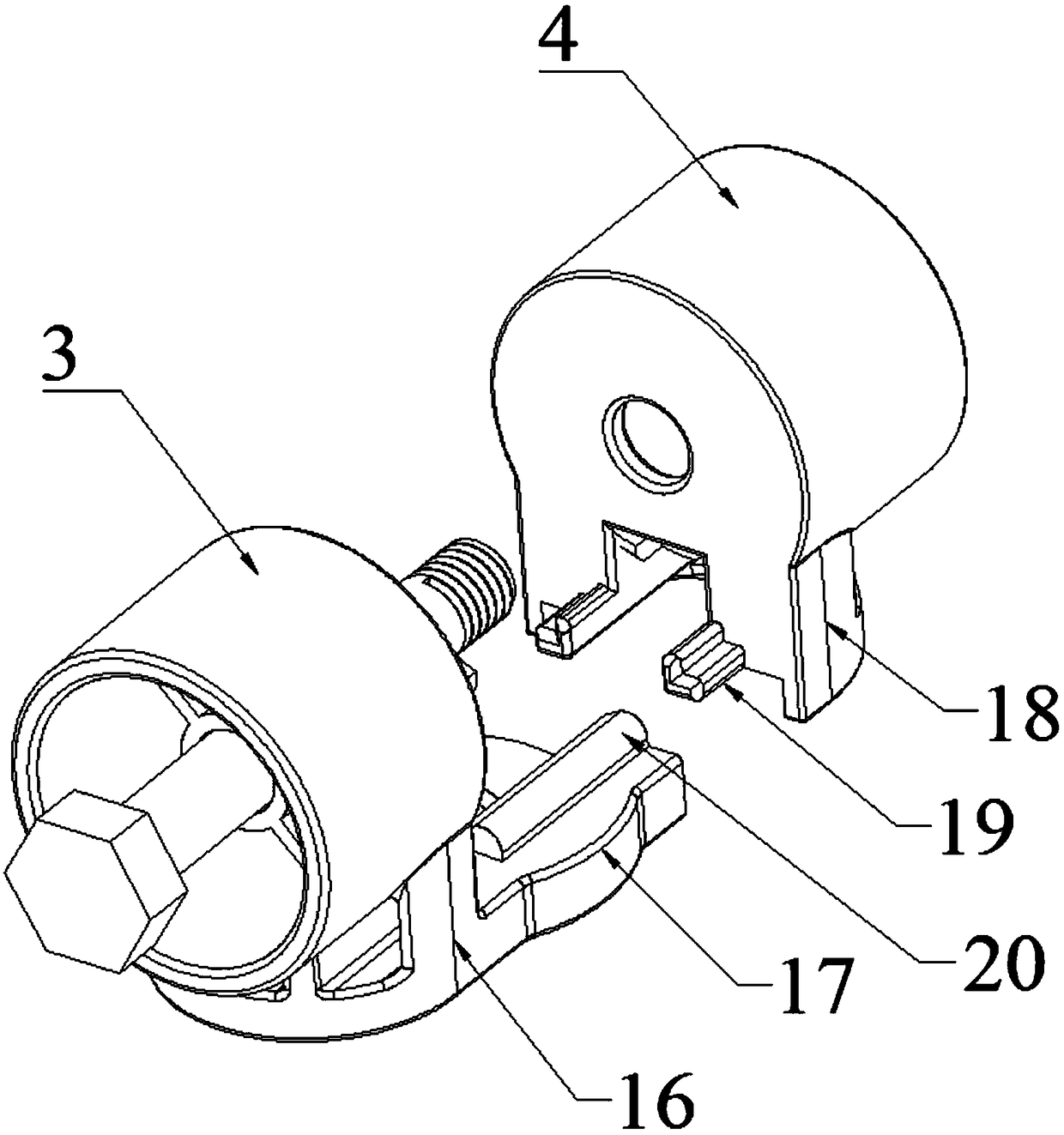

[0026] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

[0027] Such as Figure 1-Figure 3 As shown, the present invention provides a first embodiment based on a modular three-way rotating shaft structure, which is specifically as follows:

[0028] It includes a support assembly and a central axis dome 1 above the support assembly, that is, there is a gap between the central axis dome 1 and the surface of the support assembly to ensure that the central axis dome 1 can rotate normally. The side of one side and the side of the central axis round cover 1 are provided with clamping posts 2, and the clamping posts 2 are located in the radial direction of the central axis round cover 1, and the two ends of the other side are respectively connected with fixed round covers 3 and the detachable round cover 4; the same bolt rod 5 is movably socketed in the axial direction of the fixed round cover 3, the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com