Ion source with temperature control function and operating method thereof

A working method and technology of ion source, applied in the field of ion source, can solve the problems of long cooling time, slow cooling time, low utilization rate, etc., and achieve the effects of accurate heating temperature control, stable ion beam and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

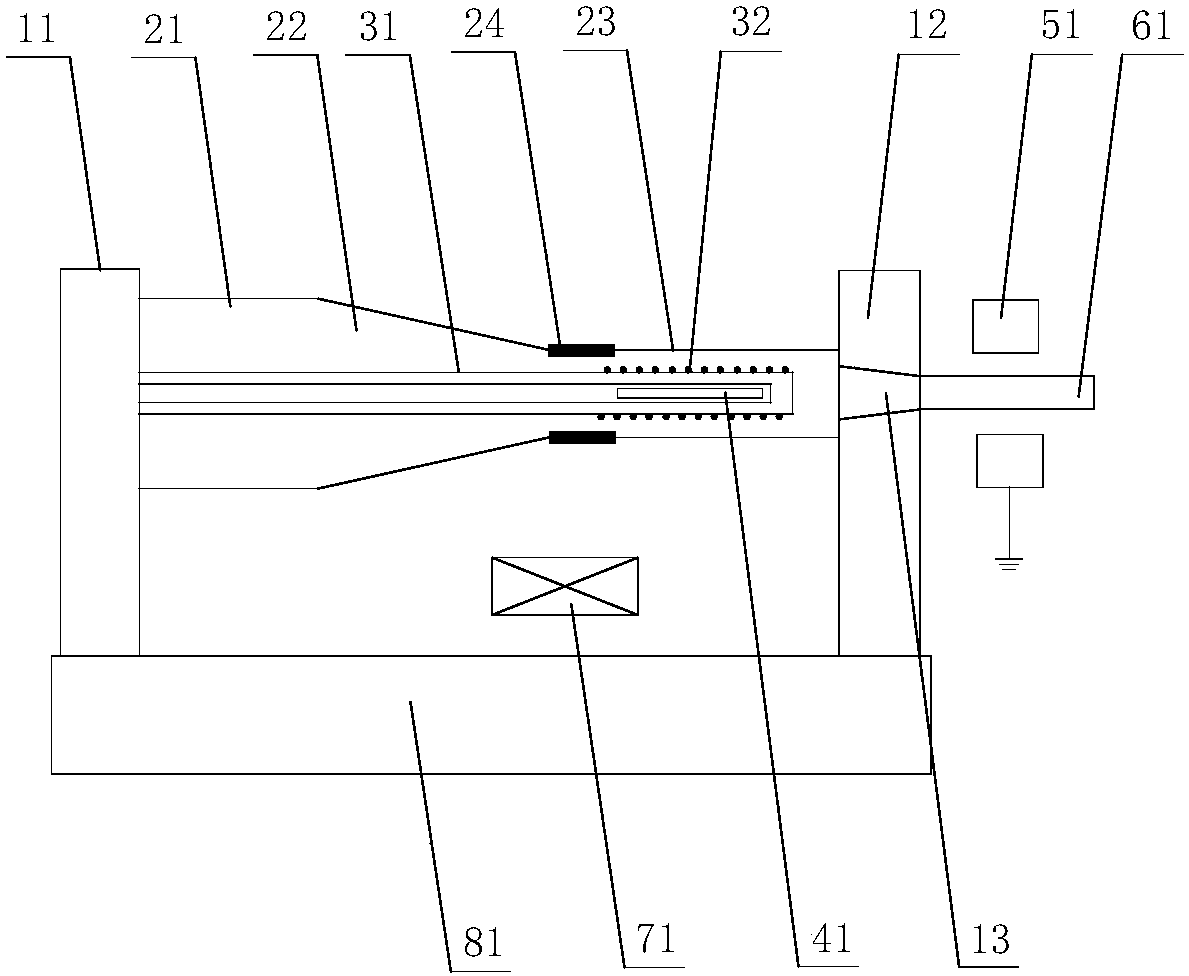

[0033] figure 1 A schematic structural diagram of an ion source with a temperature control function according to an embodiment of the present invention is schematically given, as shown in figure 1 As shown, the ion source with temperature control function includes:

[0034] A gas pipeline, the gas pipeline has a section 21 with a larger inner diameter, a transition section 22 and a section 23 with a smaller inner diameter arranged in sequence, and one end of the section with a larger inner diameter is fixed on the first bearing member;

[0035] a first section, the first section including the larger inner diameter section and a transition section;

[0036] The second part, the second part includes the section with a smaller inner diameter; the thermal conductivity of the first part is greater than that of the second part, for example, the first part is made of metal, and the second part is made of ceramics;

[0037] a connecting portion 24 connecting the first and second por...

Embodiment 2

[0060] An application example of the ion source with temperature control function described in Embodiment 1 of the present invention.

[0061] In this application example, the first part is made of stainless steel or Kovar alloy; the angle of the cone formed by the transition section is 30-60°; the angle of the cone formed by the second through hole is 30-60°; the temperature measuring part adopts Thermocouple, thermistor or platinum resistance (RTD); the cooling gas uses nitrogen or argon or air or helium; the delivery unit uses an air pump to deliver the gas to the outside of the connection between the transition section and the inner diameter section , so as to take away heat; at the same time, the heat of the smaller inner diameter section is conducted to the transition section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com