Titanium-steel composite adapter tube and equipment for adopting titanium-steel composite adapter tube

A kind of equipment and composite plate technology, which is applied in the equipment of titanium-steel composite pipe and the field of titanium-steel composite pipe, can solve the problems of easy damage to the sealing surface, easy cracking of the sealing surface, and easy cracking of the weld seam, so as to avoid cracking, Guarantee the quality of welding and the effect of welding firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

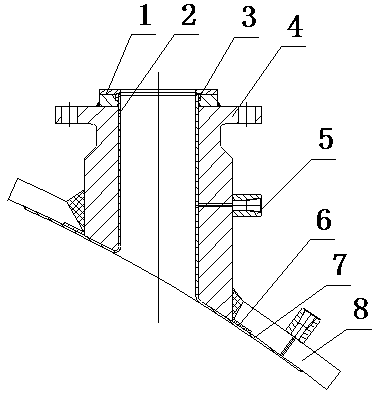

[0028] Such as Figure 1-3 As shown, the present invention provides a titanium-steel composite connecting pipe, which is suitable for titanium-steel composite plate petrochemical equipment with external connecting pipes and flanges. This composite connecting pipe can reduce the angle of the titanium lining on the equipment. The excessive concentration of stress caused by welding seams and other corresponding structures, the pipe end sealing plate and its welding structure used to form the sealing surface are firm and not easy to be damaged, which helps to avoid problems such as cracking of the sealing plate.

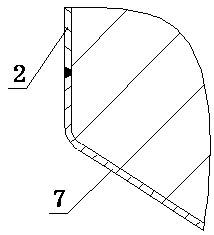

[0029] The connecting pipe body of the titanium-steel composite connecting pipe adopts a steel thick-walled reinforced connecting pipe 4, and the steel thick-walled reinforced connecting pipe 4 is lined with a titanium liner 2 to form a composite connecting pipe,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com