A preparation method and application of TPU-based microwave response 4D printing consumables

A technology of printing consumables and microwaves, applied in the direction of additive processing, etc., can solve problems such as ideas that have not been reported in the literature, and achieve excellent thermal and sensitive microwave response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

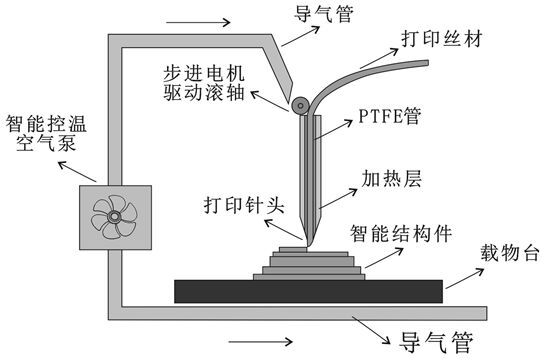

Image

Examples

Embodiment 1

[0023] (1) Dissolve 1 mass part of carbon nanotubes in 5 mass parts of dichloromethane, seal and ultrasonically disperse for 1.5 h to prepare a dispersion.

[0024] (2) Mix the dispersion prepared in step (1) with an equal volume of ε-caprolactone monomer, seal and ultrasonically disperse for 1 hour, add the catalyst, and stir and react at 130°C for 20 hours under a nitrogen atmosphere to obtain a viscous Dichloromethane whose volume is 2 times the volume of ε-caprolactone monomer was added to dilute, filtered and washed to remove impurities, precipitated in ice n-hexane, filtered and washed to remove unreacted monomers, and black powder was obtained That is, modified carbon nanotubes.

[0025] (3) Take the TPU resin and dry it in an oven at 80°C for 4 hours to obtain the dried TPU resin for later use.

[0026] (4) Weigh raw materials according to the following mass percentages: 5% of the modified carbon nanotubes obtained in step (2), 91.5% of the dried TPU resin obtained in...

Embodiment 2

[0034] (1) Dissolve 1 mass part of nano-silicon carbide in 6 mass parts of dichloromethane, seal and ultrasonically disperse for 2 hours to obtain a dispersion.

[0035] (2) Mix the dispersion prepared in step (1) with an equal volume of ε-caprolactone monomer, seal and ultrasonically disperse for 1 hour, add the catalyst, and stir and react at 130°C for 20 hours under a nitrogen atmosphere to obtain a viscous Dichloromethane whose volume is 2 times the volume of the ε-caprolactone monomer was added to dilute the mixed solution, filtered and washed to remove impurities, precipitated in ice n-hexane, filtered and washed to remove unreacted monomers, and modified nano silicon carbide.

[0036] (3) Take the TPU resin and dry it in an oven at 80°C for 4 hours to obtain the dried TPU resin for later use.

[0037] (4) Weigh raw materials according to the following mass percentages: 8% of the modified nano-silicon carbide obtained in step (2), 89.0% of the dried TPU resin obtained i...

Embodiment 3

[0045] (1) Dissolve 1 mass part of nano-zinc oxide in 4 mass parts of dichloromethane, seal and ultrasonically disperse for 2 hours to obtain a dispersion.

[0046] (2) Mix the dispersion prepared in step (1) with an equal volume of ε-caprolactone monomer, seal and ultrasonically disperse for 1 hour, add the catalyst, and stir and react at 130°C for 20 hours under a nitrogen atmosphere to obtain a viscous Dichloromethane whose volume is 2 times the volume of the ε-caprolactone monomer was added to dilute the mixed solution, filtered and washed to remove impurities, precipitated in ice n-hexane, filtered and washed to remove unreacted monomers, and modified Nano Zinc Oxide.

[0047] (3) Take the TPU resin and dry it in an oven at 80°C for 4 hours to obtain the dried TPU resin for later use.

[0048] (4) Take the raw material according to the following mass percentages: 13% of the modified nano-zinc oxide obtained in step (2), 84.0% of the dried TPU resin obtained in step (3), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com