Flexible mortar for bonding lightweight partition walls and preparation method thereof

A flexible sand, lightweight technology, applied in the field of building materials, can solve the problems of large volume shrinkage, poor anti-cracking effect, insufficient cohesion, etc., and achieve the effect of stable volume, high compressive strength, and improved compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

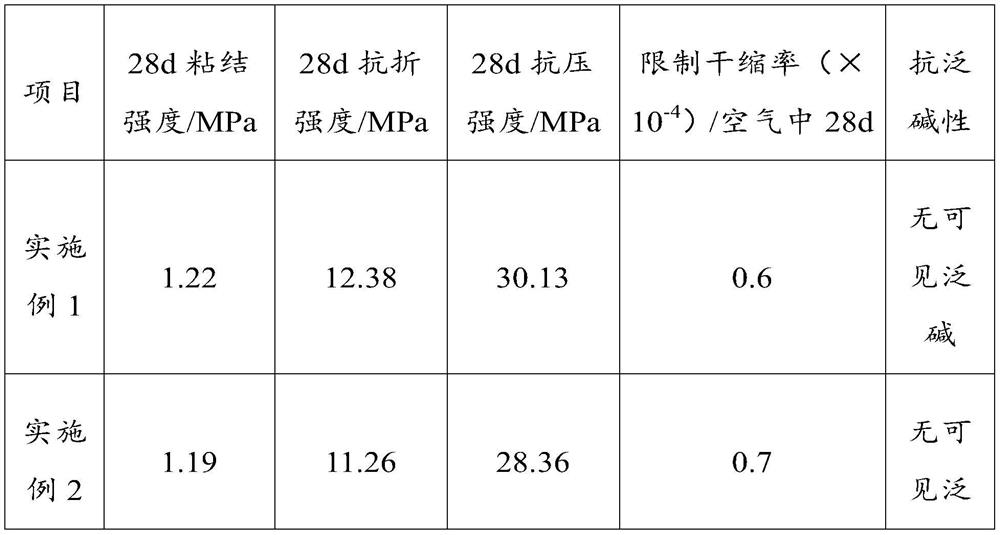

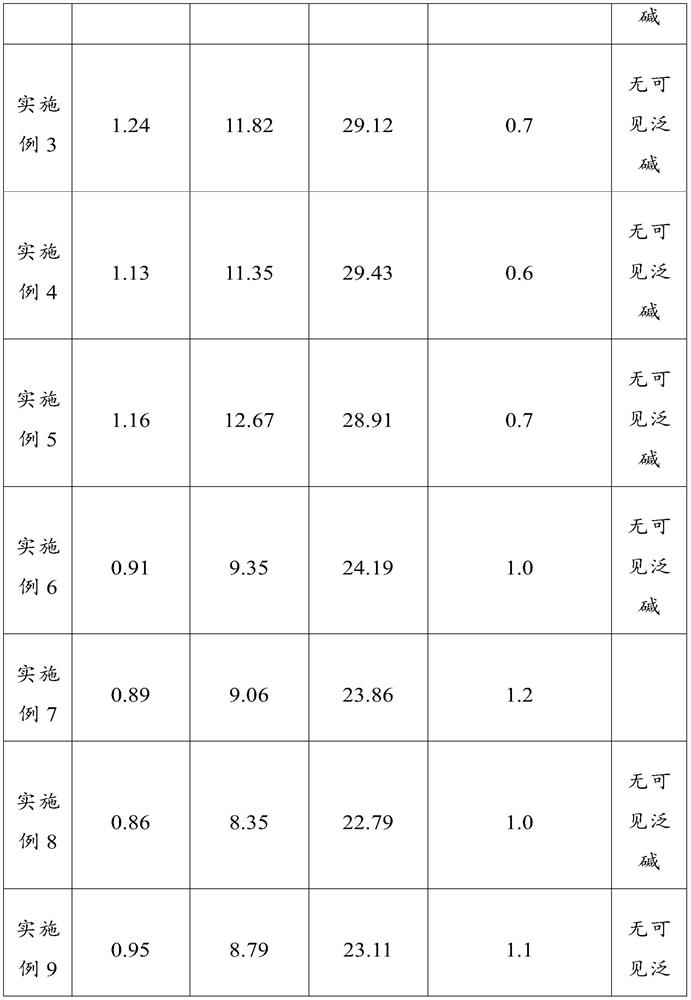

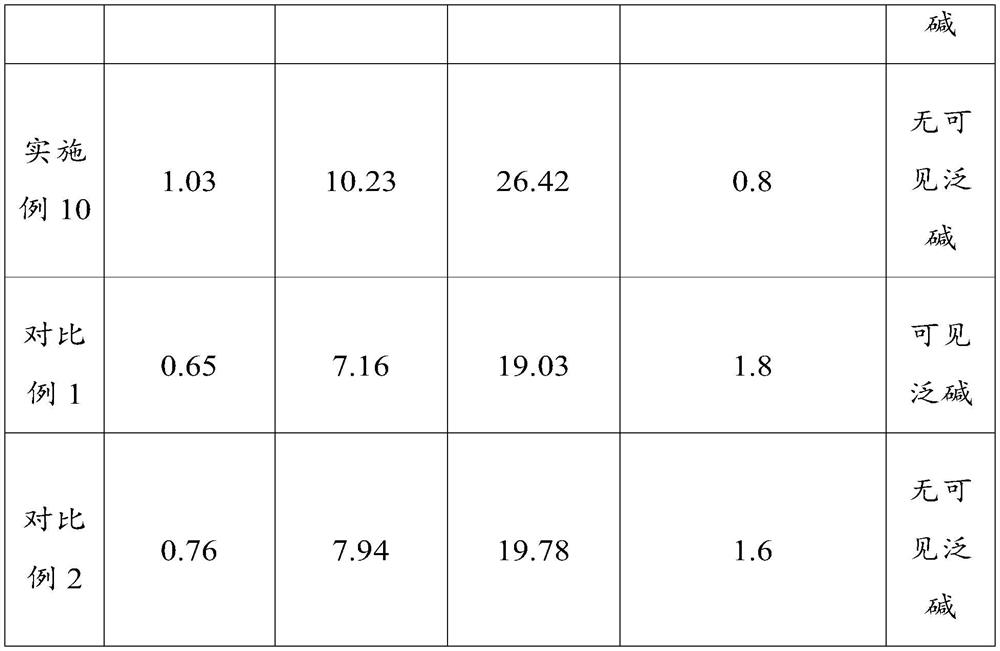

Examples

Embodiment 1

[0043] A flexible mortar for bonding lightweight partition walls, the raw materials of which include:

[0044] CA-60 aluminate cement 75kg, 42.5R ordinary Portland cement 380kg, phosphogypsum whisker 32kg, sodium phosphate 22kg, sand 450kg, expanded vermiculite powder 30kg, heavy calcium carbonate 58kg, calcined kaolin 35kg, fiber 8kg of plain ether and 36kg of rubber powder.

[0045] Among them, the calcined kaolin is composed of kaolin calcined products calcined at 550-700°C and 1100-1200°C calcined kaolin calcined products at a mass ratio of 1:2.5; the cellulose ether is composed of 3:1:1 mass ratio Composed of methylcellulose, hydroxyethylcellulose and hydroxypropylmethylcellulose.

[0046] Its preparation method includes:

[0047] S1. Mix and stir aluminate cement, ordinary Portland cement, phosphogypsum whiskers, sodium sulfate and 40% sand to obtain the first mixture.

[0048] S2. Mix and stir the first mixture, 40% expanded vermiculite powder, heavy calcium carbonat...

Embodiment 2

[0051] A flexible mortar for bonding lightweight partition walls, the raw materials of which include:

[0052] CA-60 aluminate cement 70kg, 42.5R ordinary Portland cement 400kg, phosphogypsum whisker 32kg, sodium phosphate 23kg, sand 440kg, expanded vermiculite powder 32kg, heavy calcium carbonate 55kg, calcined kaolin 38kg, fiber 6kg of plain ether and 38kg of rubber powder.

[0053] Among them, the calcined kaolin is composed of kaolin calcined products calcined at 550-700°C and 1100-1200°C calcined kaolin calcined products at a mass ratio of 1:3; the cellulose ether is composed of 4:1:1 mass ratio Composed of methylcellulose, hydroxyethylcellulose and hydroxypropylmethylcellulose.

[0054] Its preparation method includes:

[0055] S1. Mix and stir aluminate cement, ordinary portland cement, phosphogypsum whiskers, sodium sulfate and 45% sand to obtain the first mixture.

[0056] S2. Mix and stir the first mixture, 30% expanded vermiculite powder, heavy calcium carbonate,...

Embodiment 3

[0059] A flexible mortar for bonding lightweight partition walls, the raw materials of which include:

[0060] CA-60 aluminate cement 80kg, 42.5R ordinary Portland cement 360kg, phosphogypsum whisker 34kg, sodium phosphate 21kg, sand 460kg, expanded vermiculite powder 28kg, heavy calcium carbonate 60kg, calcined kaolin 32kg, fiber 8kg of plain ether and 36kg of rubber powder.

[0061] Among them, the calcined kaolin is composed of kaolin calcined products calcined at 550-700°C and 1100-1200°C calcined kaolin calcined products at a mass ratio of 1:2; the cellulose ether is composed of 3:0.5:1 mass ratio Composed of methylcellulose, hydroxyethylcellulose and hydroxypropylmethylcellulose.

[0062] Its preparation method includes:

[0063] S1. Mix and stir aluminate cement, ordinary Portland cement, phosphogypsum whiskers, sodium sulfate and 30% sand to obtain the first mixture.

[0064] S2. Mix and stir the first mixture, 50% expanded vermiculite powder, heavy calcium carbonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com