Seam-filling mortar for treating cracks in lightweight partition walls and preparation method thereof

A partition wall and seam repairing technology, which is applied in the field of joint repair mortar and its preparation for dealing with cracks in light partition walls, can solve the problems of cracks at the connection between wall boards and structural parts that cannot meet the requirements of light wall board seam repair operations, Solve problems such as cracking of light-weight partition wall slats, and achieve the effect of avoiding the deterioration of microstructure, avoiding incomplete filling and stable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

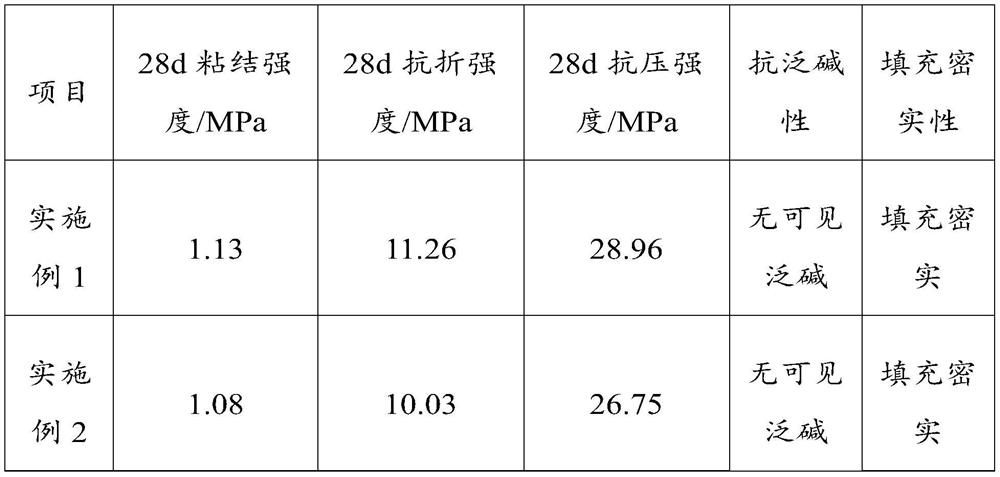

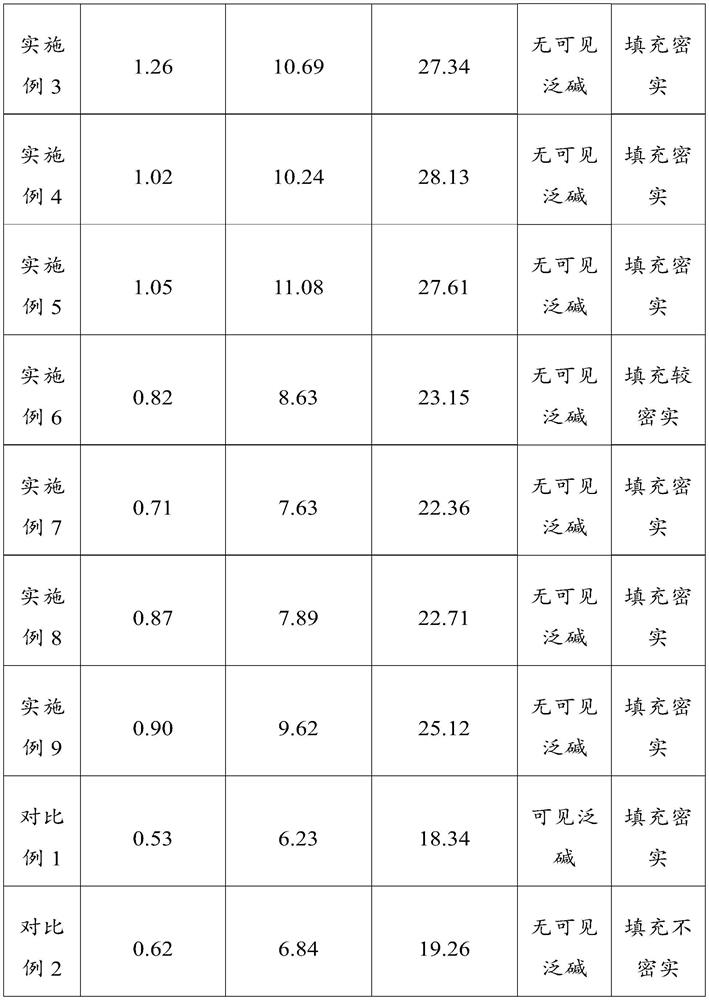

Examples

Embodiment 1

[0046] A joint filling mortar for treating cracks in lightweight partition walls, the raw materials of which include:

[0047] CA-60 aluminate cement 98kg, 42.5R ordinary Portland cement 360kg, phosphogypsum whiskers 26kg, sodium sulfate 20kg, fine sand 165kg, medium sand 220kg, coarse sand 128kg, fly ash 62kg, cellulose Ether 5kg and rubber powder 40kg.

[0048] Among them, fine sand is composed of river sand and sea sand with a mass ratio of 5:1; medium sand is composed of river sand, sea sand and mountain sand with a mass ratio of 4:1:1; coarse sand is composed of a mass ratio of 3:1 It is composed of river sand and mountain sand; cellulose ether is composed of methyl cellulose, hydroxyethyl cellulose and hydroxypropyl methyl cellulose with a mass ratio of 3:1:1.

[0049] Its preparation method includes:

[0050] S1. Mix and stir aluminate cement, ordinary Portland cement, phosphogypsum whiskers, sodium sulfate and fine sand for 5-8 minutes to obtain the first mixture.

...

Embodiment 2

[0054] A joint filling mortar for treating cracks in lightweight partition walls, the raw materials of which include:

[0055] CA-60 aluminate cement 90kg, 42.5R ordinary Portland cement 370kg, phosphogypsum whiskers 26kg, Yuan Mingfen 22kg, fine sand 170kg, medium sand 210kg, coarse sand 130kg, fly ash 55kg, fiber 6kg of plain ether and 40kg of rubber powder.

[0056] Among them, fine sand is composed of river sand and sea sand with a mass ratio of 4:1; medium sand is composed of river sand, sea sand and mountain sand with a mass ratio of 4:2:1; coarse sand is composed of a mass ratio of 2:1 It is composed of river sand and mountain sand; cellulose ether is composed of methyl cellulose, hydroxyethyl cellulose and hydroxypropyl methyl cellulose with a mass ratio of 3:2:1.

[0057] Its preparation method includes:

[0058] S1. Mix and stir aluminate cement, ordinary Portland cement, phosphogypsum whiskers, sodium sulfate and fine sand for 5-8 minutes to obtain the first mixtu...

Embodiment 3

[0062] A joint filling mortar for treating cracks in lightweight partition walls, the raw materials of which include:

[0063] CA-60 aluminate cement 100kg, 42.5R ordinary Portland cement 350kg, phosphogypsum whiskers 28kg, Yuan Mingfen 20kg, fine sand 160kg, medium sand 230kg, coarse sand 125kg, fly ash 70kg, cellulose Ether 4kg and rubber powder 44kg.

[0064] Among them, fine sand is composed of river sand and sea sand with a mass ratio of 4:1; medium sand is composed of river sand, sea sand and mountain sand with a mass ratio of 3:2:1; coarse sand is composed of a mass ratio of 2.5:1 It is composed of river sand and mountain sand; cellulose ether is composed of methyl cellulose, hydroxyethyl cellulose and hydroxypropyl methyl cellulose with a mass ratio of 2:1:1.

[0065] Its preparation method includes:

[0066] S1. Mix and stir aluminate cement, ordinary Portland cement, phosphogypsum whiskers, sodium sulfate and fine sand for 5-8 minutes to obtain the first mixture. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com