Duct piece overturning machine

A technology of turning and segmenting, which is applied in the field of segment transportation equipment, can solve the problems of easy bumping and damage of segments, inconvenient unification, and large difference between segments, so as to save cycle time, improve work efficiency, save time and manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will be described in detail in conjunction with the accompanying drawings and specific embodiments.

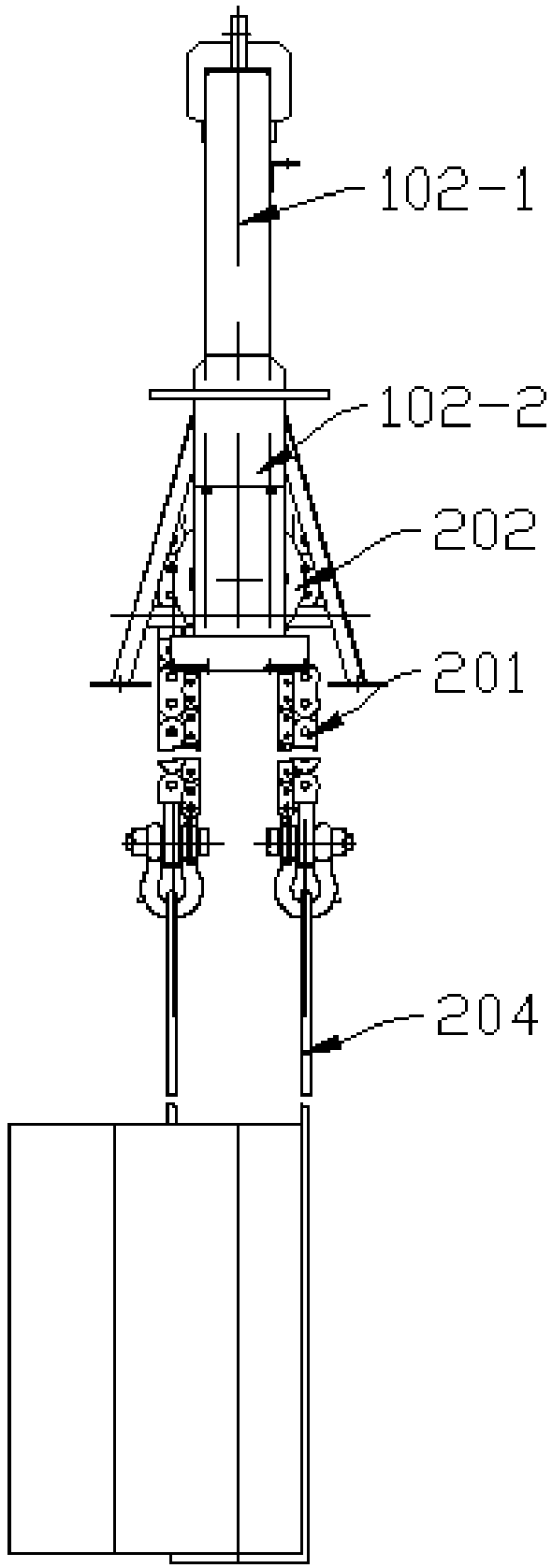

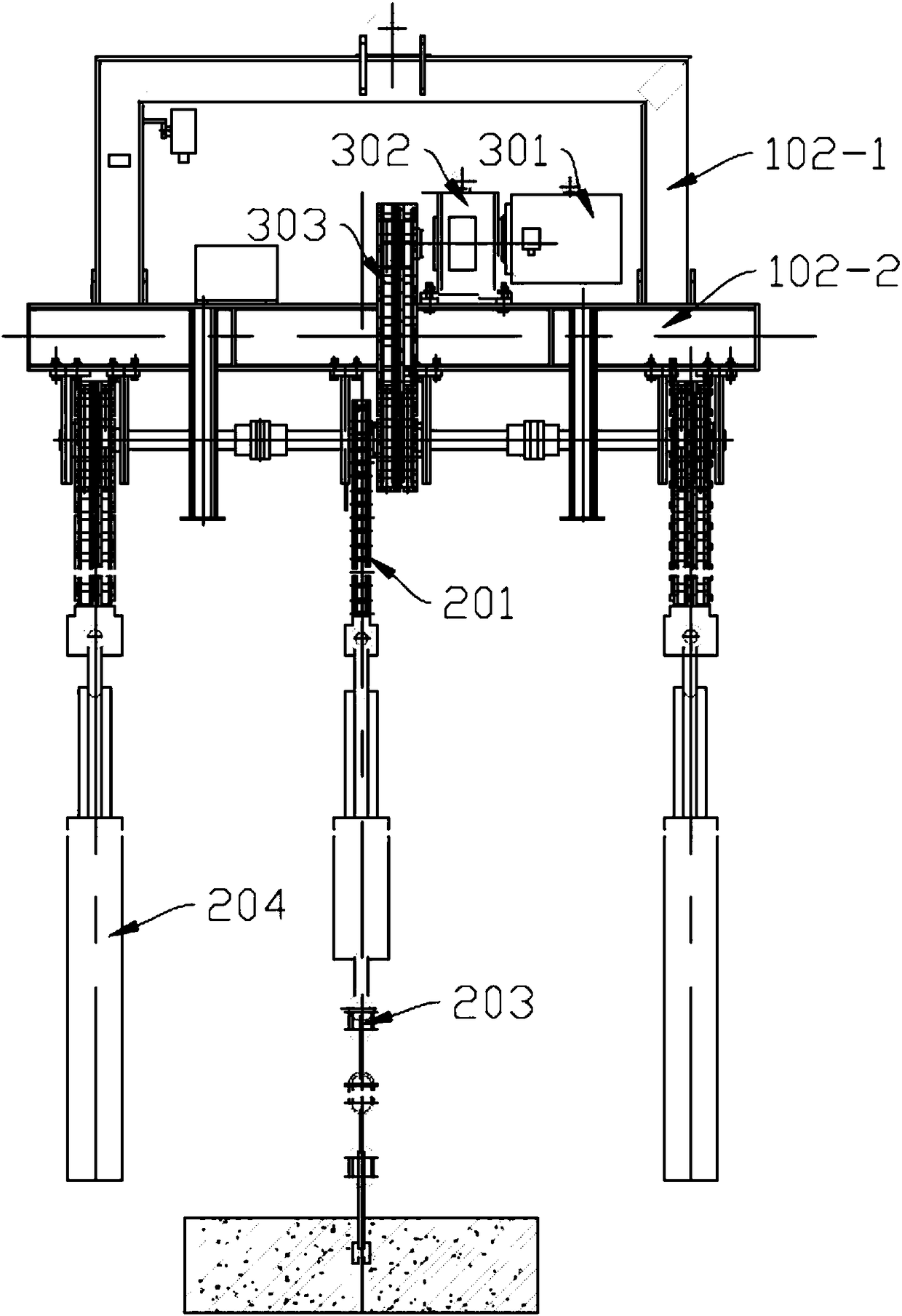

[0028] like Figure 1-4 As shown, a tube turning machine includes a moving device, a first transmission device, a driving device and a second transmission device. Wherein, the driving device is installed on the mobile device and drives the first transmission device, and the two ends of the first transmission device are respectively connected to drive a second transmission device; the first transmission device and each second transmission device include two It is used to connect the segment and the output end with the opposite output direction. The output direction of the output end is the vertical direction; the moving device moves up and down, left and right, forward and backward, so as to control the first transmission device, the second transmission device and drive the displacement of the device freely Spend.

[0029] When handling standard blocks or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com