A sensor welding jig

A welding fixture and sensor technology, applied in welding equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of reducing production efficiency, increasing production cost, unsightly welding seam, etc., achieving high production efficiency, zero scrap rate, welding Reliable quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

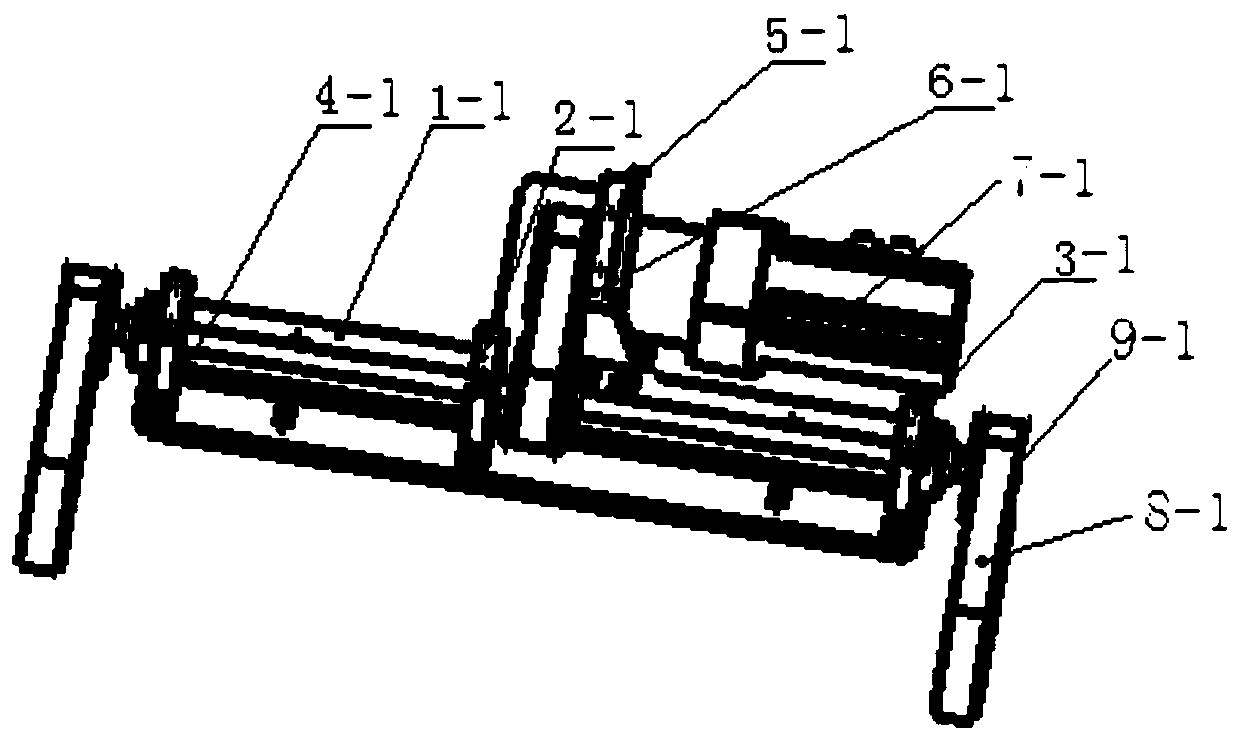

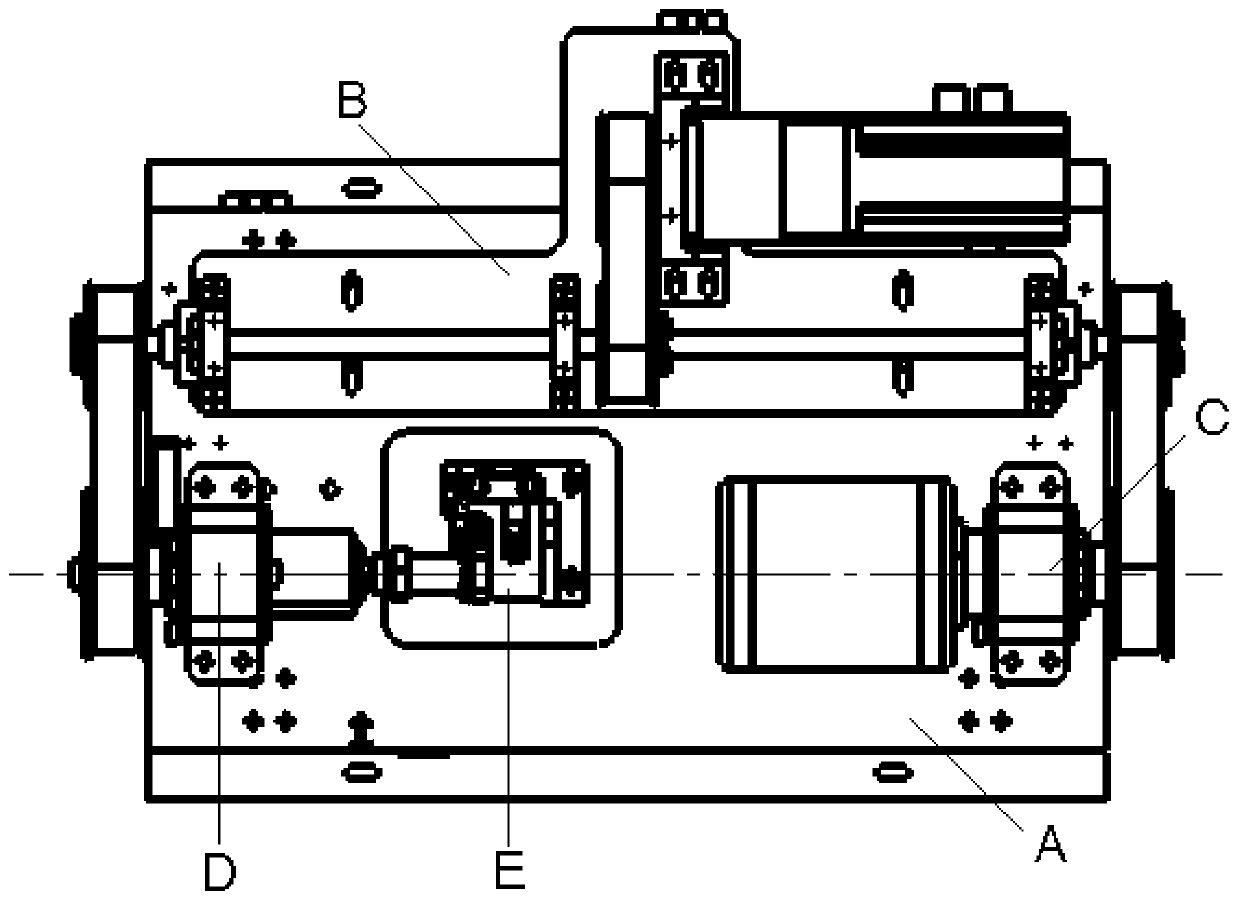

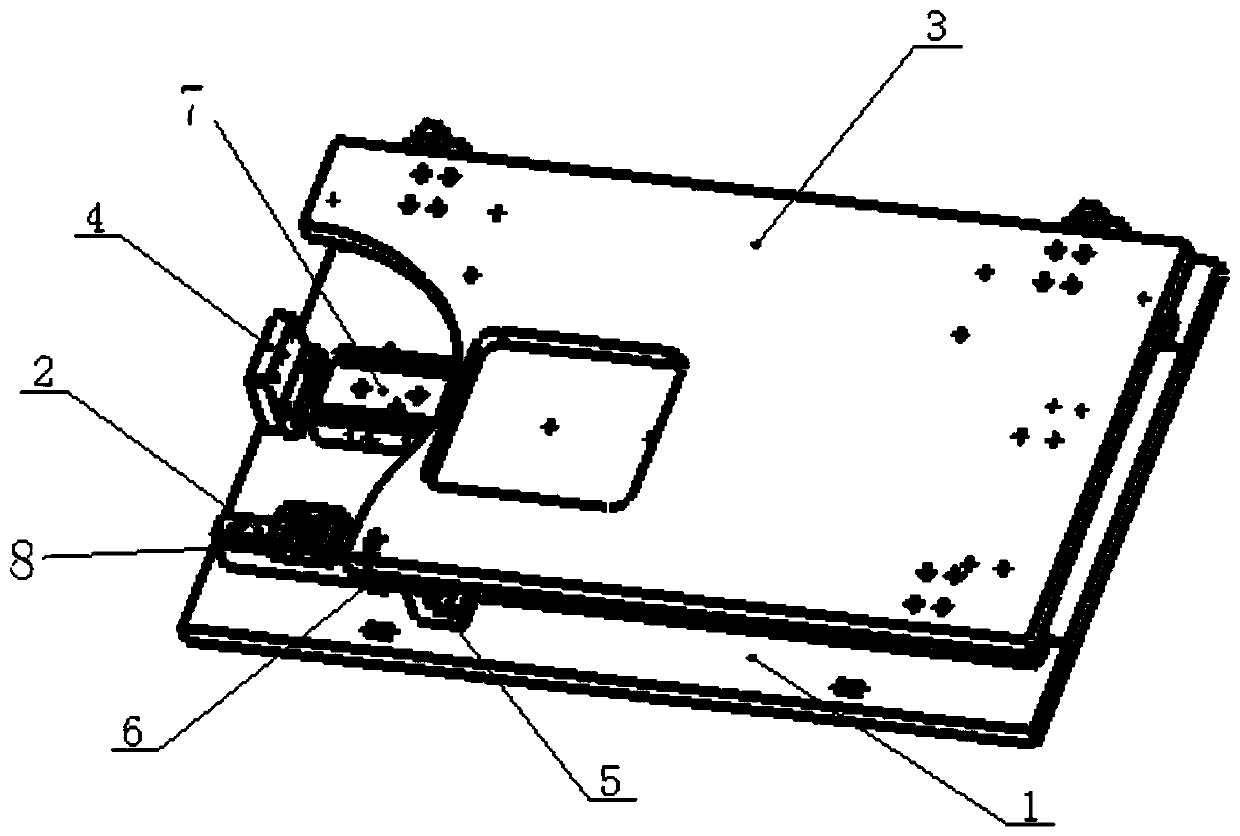

[0031] See attached Figure 1-10 , a sensor welding fixture of the present invention is composed of a base assembly, a motor rotating assembly, a wire-receiving follow-up assembly, a rotating assembly, and a support assembly, and the motor rotating assembly, the wire-receiving follow-up assembly, the rotating assembly, and the support assembly Installed on the base assembly respectively, the motor rotation assembly is respectively connected with the rotation assembly and the follow-up assembly through two pulleys, and the rotation assembly is connected with the support assembly; when the equipment is in operation, the motor rotation assembly is equipped with a photoelectric sensor, The photoelectric sensor is used as the initiator of the signal to ensure the consistency and stability of the welding of the workpiece during the welding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com