Hydraulic drilling and milling fixture for shaft spare part and use method of hydraulic drilling and milling fixture

A technology for hydraulic fixtures and shaft parts, which is used in metal processing machinery parts, manufacturing tools, toolholder accessories, etc., can solve the problems of low degree of automation, poor interchangeability, and cannot be applied to automated production, and achieves high machining accuracy. The effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is described in further detail below in conjunction with accompanying drawing:

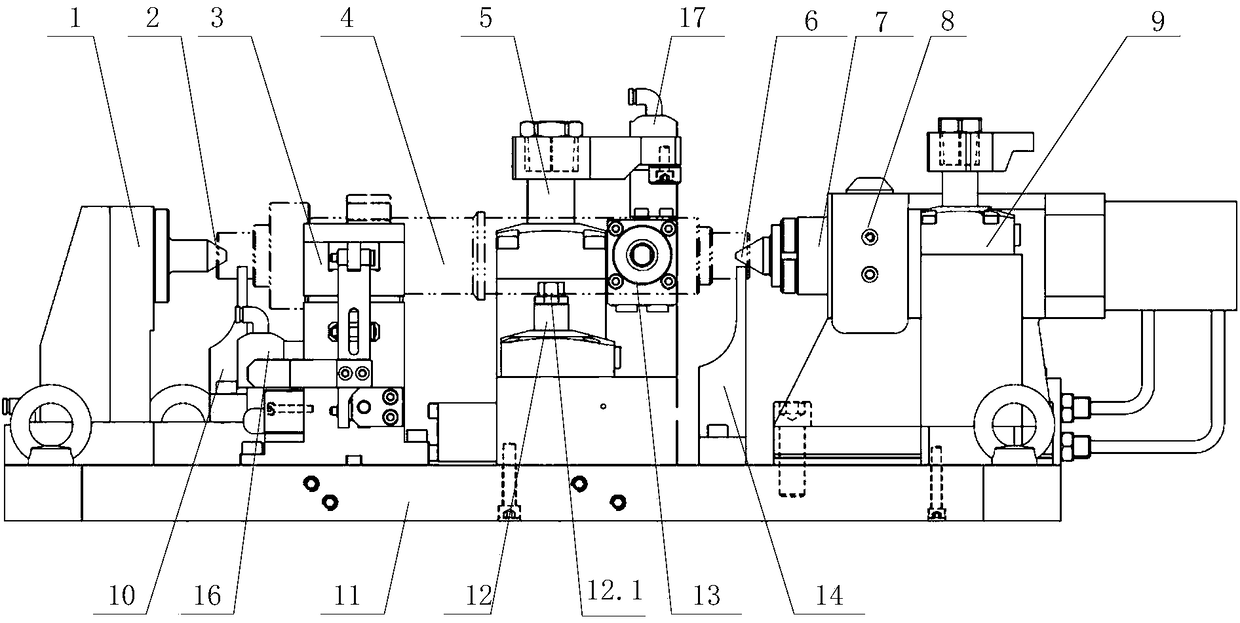

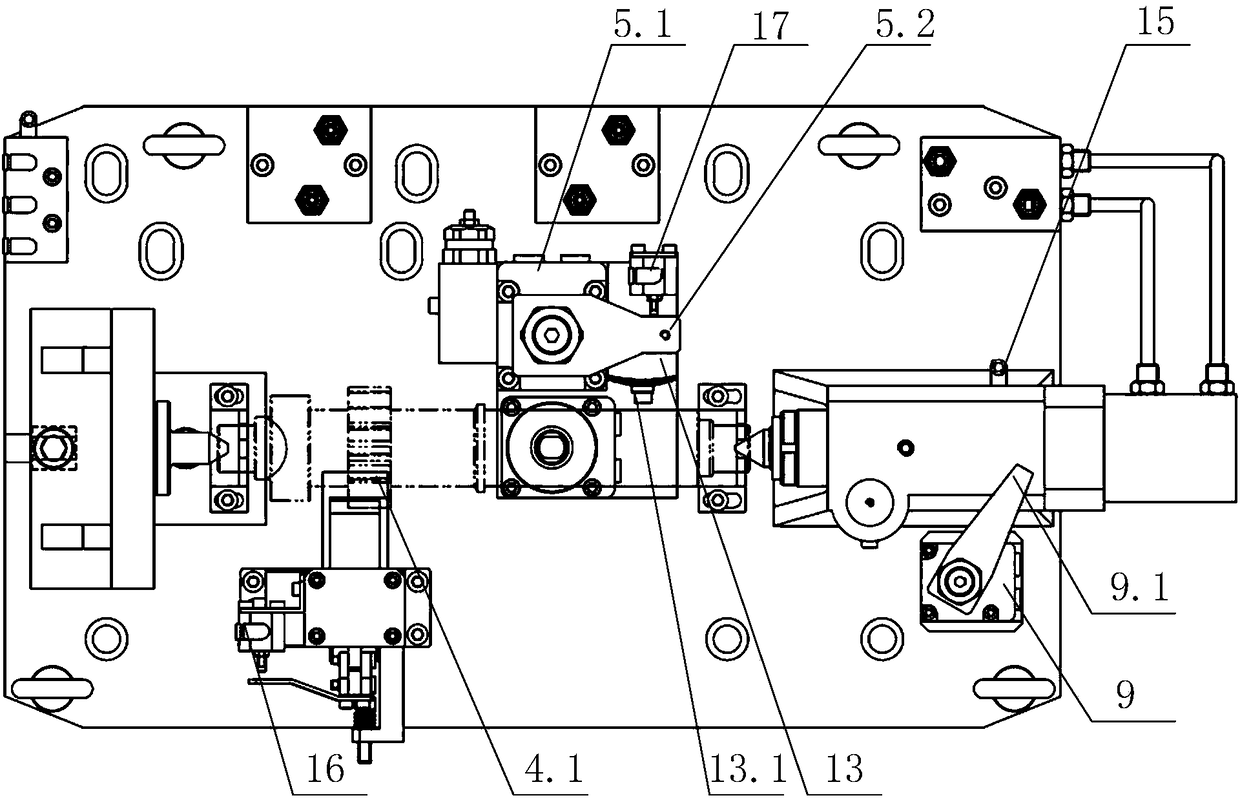

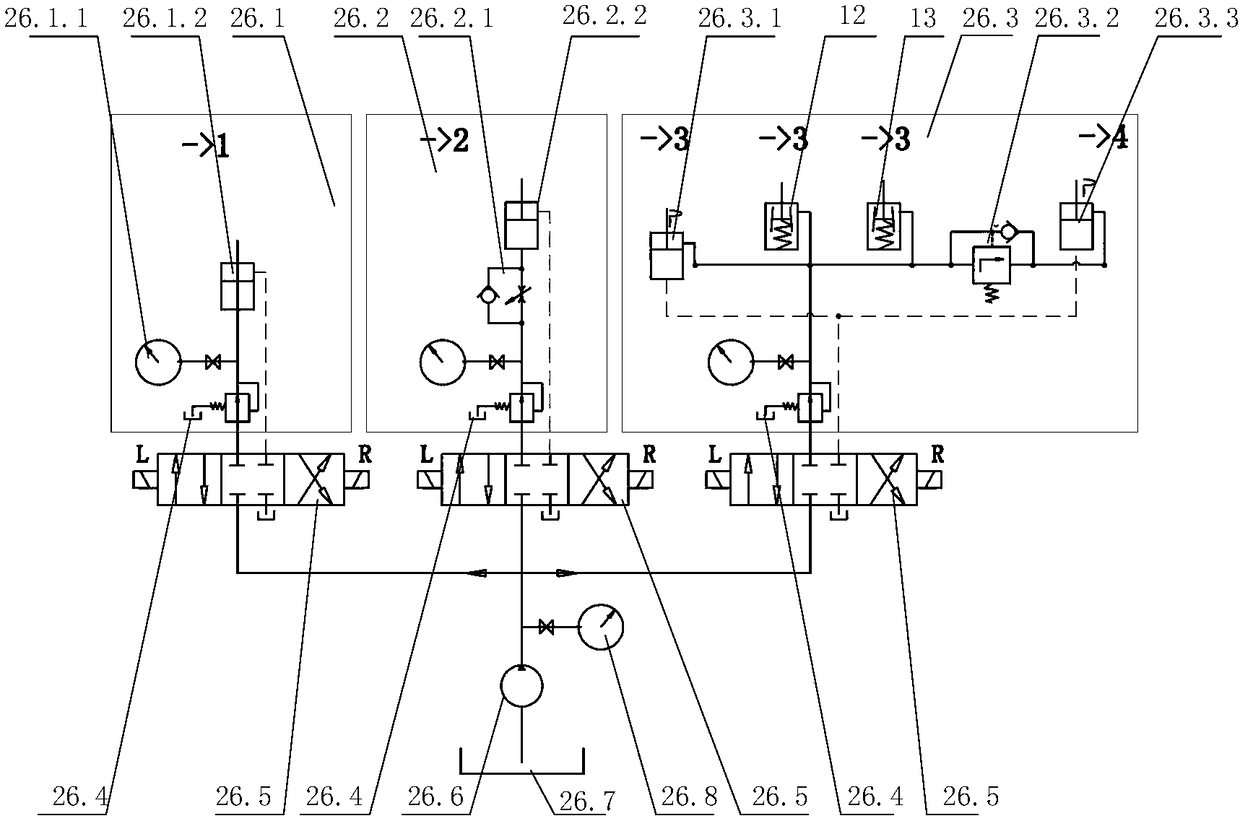

[0050] see figure 1 and figure 2 , The invention relates to a drilling and milling hydraulic automatic fixture for shaft parts and a method for using the same. The hydraulic automation fixture for drilling and milling of shaft parts includes a bottom plate 11, a top seat assembly 1 installed on the bottom plate 11 in sequence with the center line being the same straight line, a first support frame 10, a first support 12, and a second support frame 14 and tailstock assembly 7, wherein the top seat assembly 1 can move along the workpiece axis on the bottom plate 11, and the rest are fixed installations; the workpiece 4 is pre-installed on the first support frame 10 and the second support frame 14, and then clamped Between the top seat assembly 1 and the tailstock assembly 7, the bottom plate 11 is equipped with a tooth gauge assembly 3 on one side of the workpiece 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com