Manipulator for pasting double-sided tape on car seat cushions

A technology for double-sided tape and car seat cushion, which is applied in the directions of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of high labor intensity and hinder the full automation of the production process of car seat cushions, and achieves simple structure, realization of process automation, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with the preferred embodiment shown in accompanying drawing, be described in further detail:

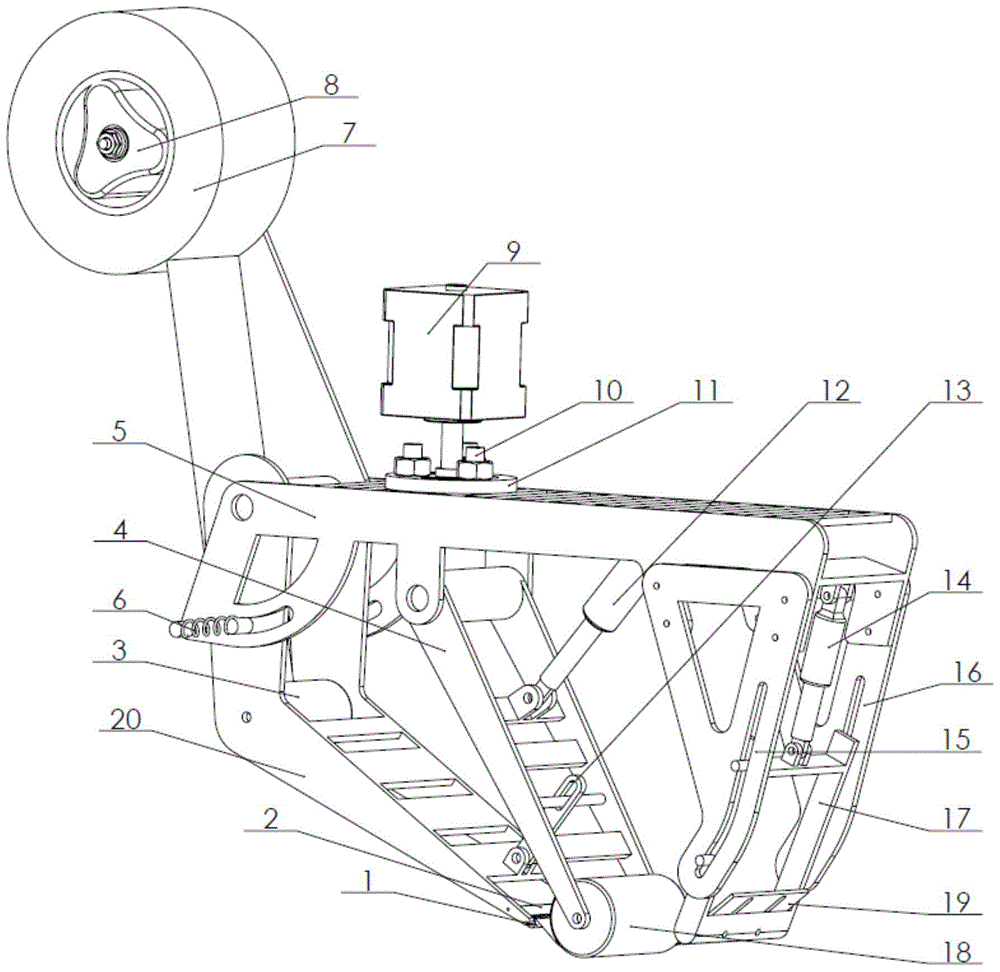

[0011] Such as figure 1 As shown, the described manipulator for sticking double-sided adhesive tape on automobile seat cushions includes a main support 5, which is characterized in that the main support 5 is provided with a pressing belt support 4 and a belt guide support 20, and the tape roller 7 passes through the tape roller. The lining 8 is installed on the upper part of the belt guide bracket 20, and the stepping motor 9 is fixedly installed on the main bracket 5 through the flange plate 11 and the bolt 10. The belt guide bracket 20 is also correspondingly provided with a coarse roller 3 for conveying the tape , pressing plate 2 and fine roller 1, the pressure roller 18 is installed at the lower end of the described pressure belt support 4, a pull rod 13 is arranged between the pressure belt support 4 and the guide belt support 20, and a There is a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com