Integrated garbage pretreatment technology

A technology of pretreatment and garbage, applied in the direction of solid waste removal, etc., can solve the problems of the difficulty of step-by-step sorting of garbage pre-treatment, the inability to directly recycle garbage, and the large amount of water used for garbage cleaning, so as to avoid the problem of step-by-step sorting. Sorting process, saving manpower and waste disposal cost, effect of reducing disposal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

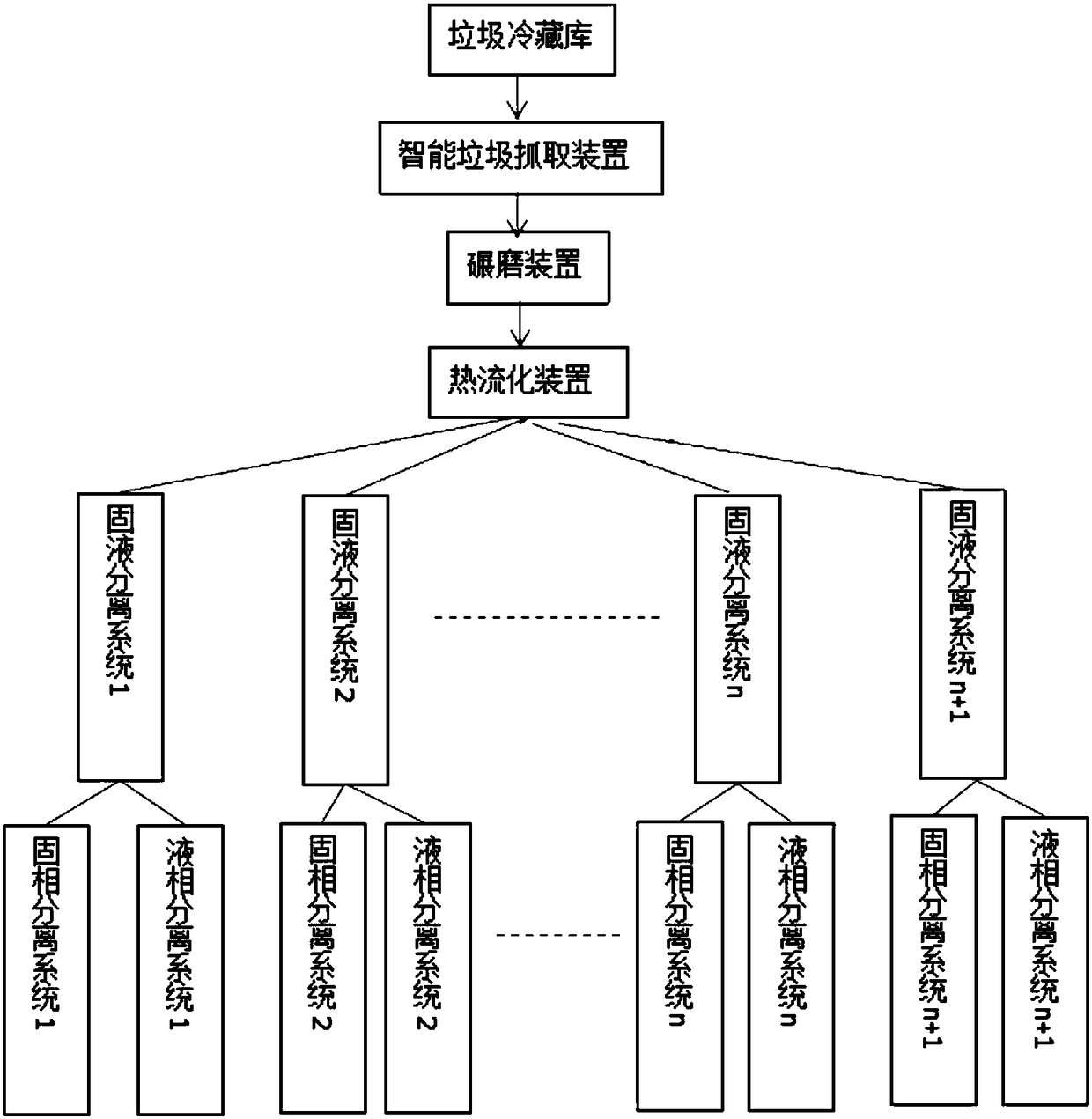

[0024] The technical solutions in the present invention will be further described below with reference to the accompanying drawings and embodiments.

[0025] Refer to the attached figure 1 , a comprehensive waste pretreatment process, comprising the following steps:

[0026] 1) Transport the garbage to the garbage cold storage built in the garbage disposal station for storage;

[0027] 2) Through the intelligent garbage grabbing device, the garbage stored in the cold storage is grabbed and put into the grinding device for grinding, and the particle size of the ground garbage particles is less than 100 mesh;

[0028] 3) transporting the finely ground garbage particles in step 2) to a thermal fluidization device for fluidized cleaning;

[0029] 4) The garbage particles and cleaning liquid in the thermal fluidization device are transported to multiple solid-liquid separation systems through the smart pipe network conveying system for step-by-step solid-liquid separation to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com