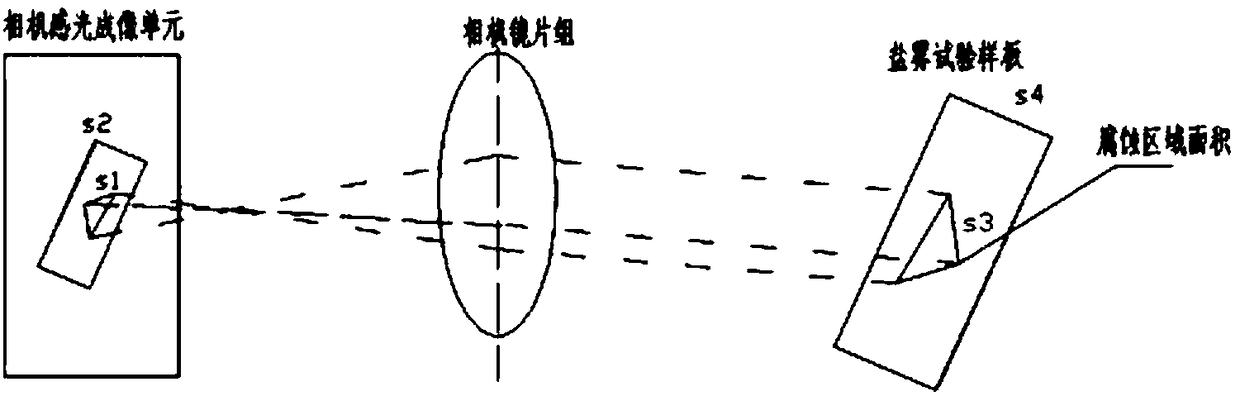

Salt spray test relative corrosion area measurement method

A salt spray test, corrosion area technology, used in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of high pixel dependence, regular system and software upgrades, inconvenient operation, etc., to achieve clear pictures , the effect of low pixel dependence and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Make paper samples such as Figure 5 , the length is 150mm, and the width is 75mm. Any angle in the sample is transformed into a square and an isosceles right triangle, representing the corrosion area, and the side length is 20mm;

[0062] Mobile phone camera samples to ensure that the pictures are clear, and the naked eye can distinguish the corroded area from the uncorroded area;

[0063] Paste the picture into the white background AUTOCAD software;

[0064] Use the PL command to draw a finite closed polygon to fit the corrosion area and the total area of the test sample;

[0065] Use the LI command to calculate the area of each corrosion area and the area of the entire sample;

[0066] Comparing the addition of each corrosion area with the total area of the sample to calculate the relative corrosion area, the calculation results are shown in Figure 10 , the difference between the fitting value and the actual value is 0.02%, indicating that the accuracy of...

Embodiment 2

[0068] Preparation of salt spray test samples, such as Image 6 shown;

[0069] Salt spray test according to national standards;

[0070] After 72 hours of salt spray test, rinse the sample sample with desalted water, let it stand for 0.5-1 hour, blow it dry with a hair dryer, and wipe it clean with test paper;

[0071]Take photos of the salt spray test sample with the mobile phone to ensure that the picture is clear, and the naked eye can distinguish the corroded area from the uncorroded area;

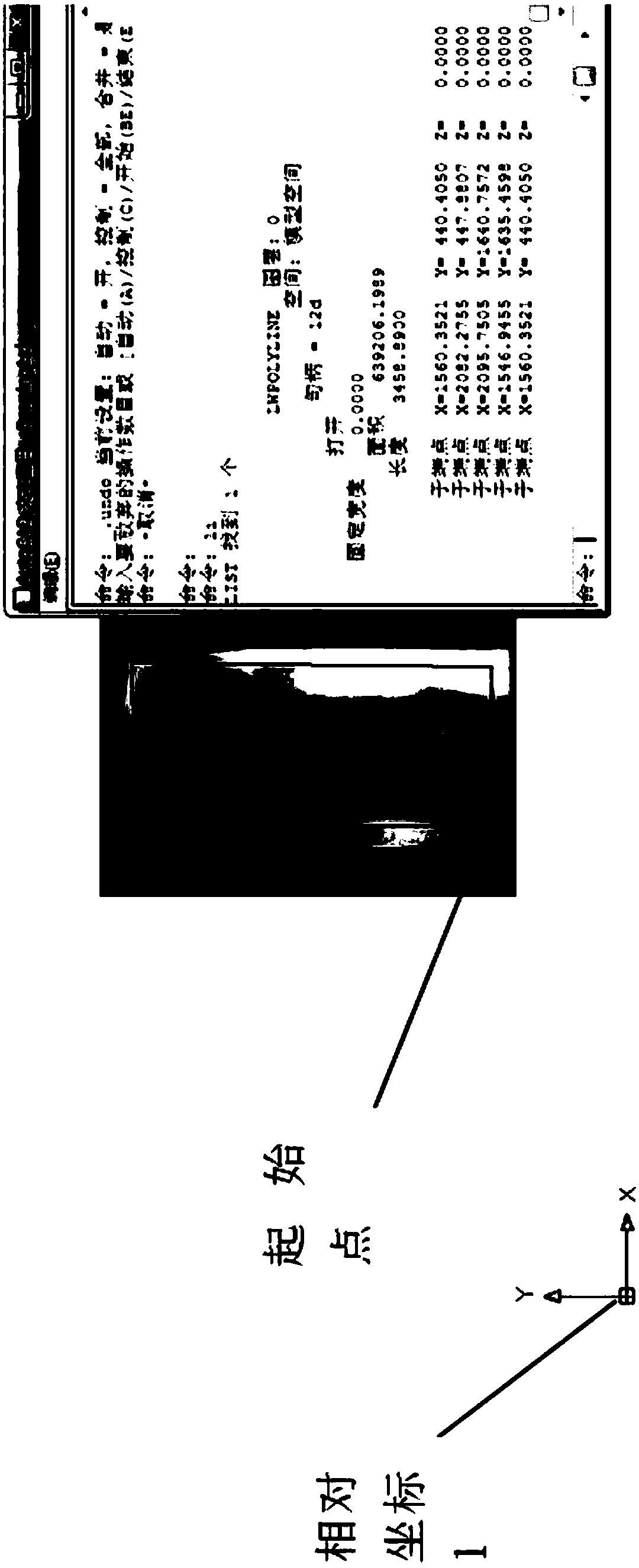

[0072] Paste the picture into AUTOCAD software with white background; AUTOCAD version is 2004 and above;

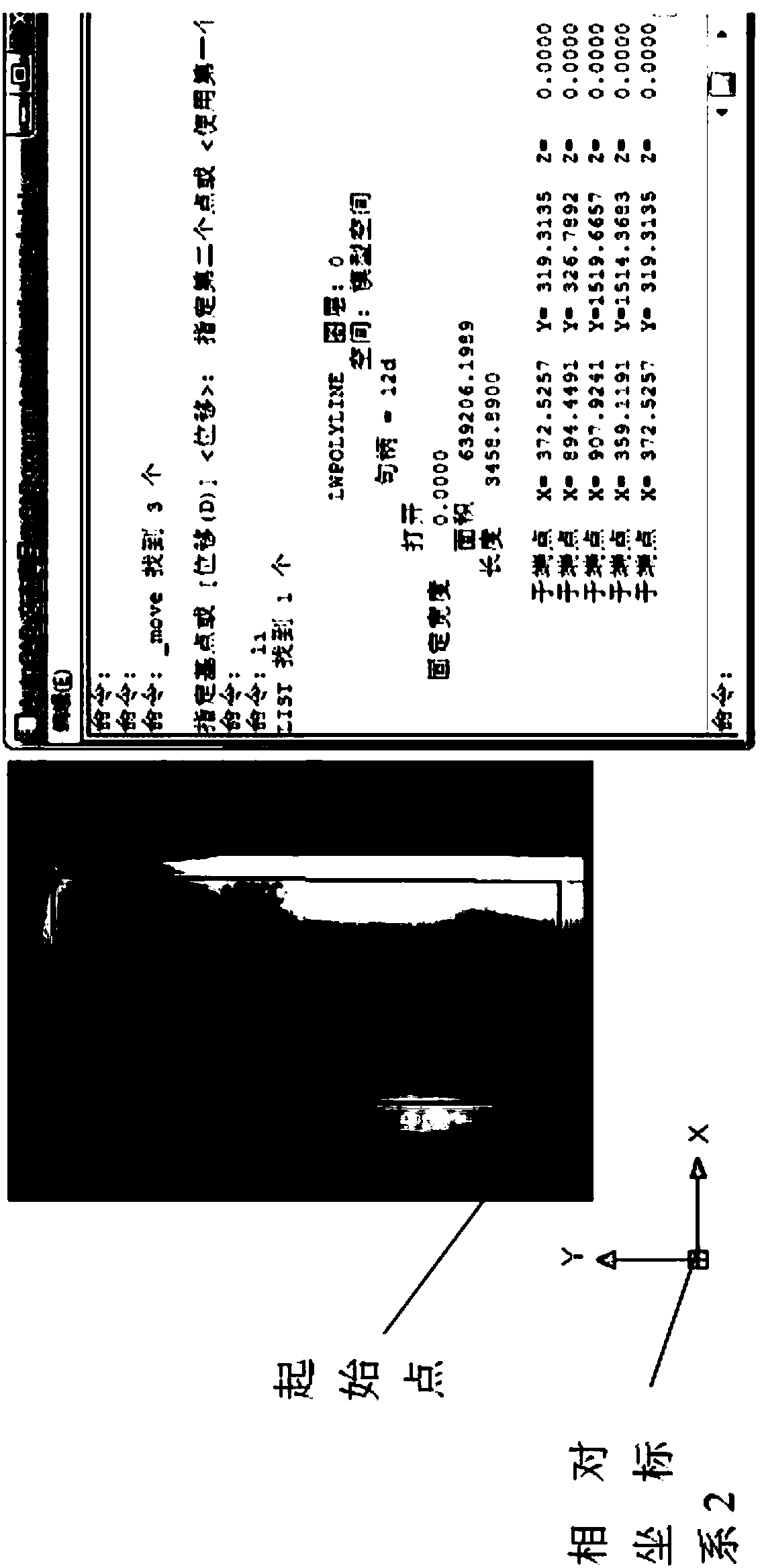

[0073] Use the PL command to draw a finite closed polygon to fit the corrosion area and the total area of the test sample; see Figure 7 with Figure 8 ;

[0074] Use the LI command to calculate the area of each corrosion area and the area of the entire sample; see Figure 9 ;

[0075] The relative corrosion area is calculated by comparing the addition of each corros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com