Method for nondestructively detecting asphalt pavement crack conditions

A technology for asphalt pavement and non-destructive testing, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of expensive equipment, core sample removal, and low precision, and achieve the effects of simple operation, low cost and accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

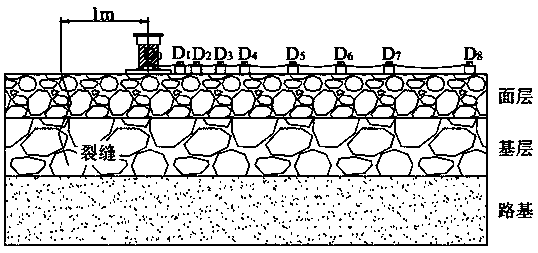

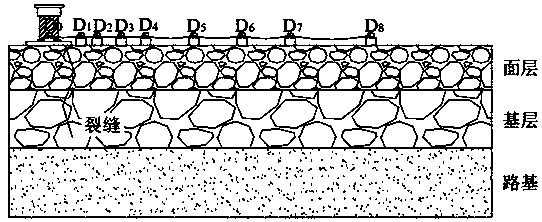

[0018] In order to solve the defects of high implementation cost, low detection accuracy and complicated operation existing in the existing non-destructive testing technology, the idea of the present invention is to use the drop weight deflection instrument to realize the accurate detection of the downward extension of asphalt pavement cracks. and non-destructive testing.

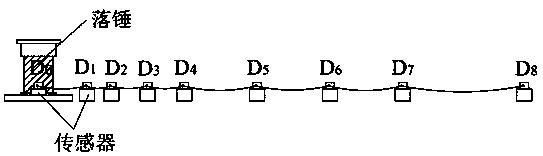

[0019] The Falling Weight Deflectormeter (FWD for short) was produced in the early 1970s. It is a pulse dynamic deflector. It simulates the instantaneous impact of the vehicle load on the road surface to obtain the instantaneous deformation of the road surface. The measurement results are more accurate and have a large amount of information. Its working principle is: under the control of the computer, the weight of a certain mass is lifted to a certain height by the hydraulic transmission device and then falls freely. The impact force acts on the bearing plate and is transmitted to the road surface, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com