Preignition detection method for internal combustion engine

A detection method and internal combustion engine technology, applied in the direction of internal combustion engine testing, etc., can solve the problems of low signal response speed of cooling water temperature sensor, ineffective real-time monitoring of abnormal combustion, failure of early combustion detection of anti-knock fuel, etc., and achieve high speed correction accuracy and good performance Application prospects in the real vehicle environment and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

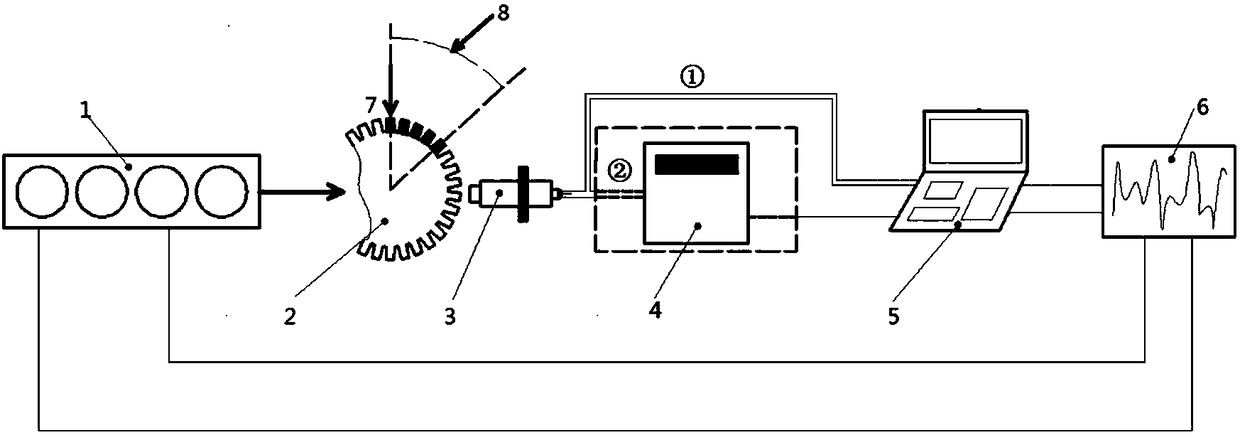

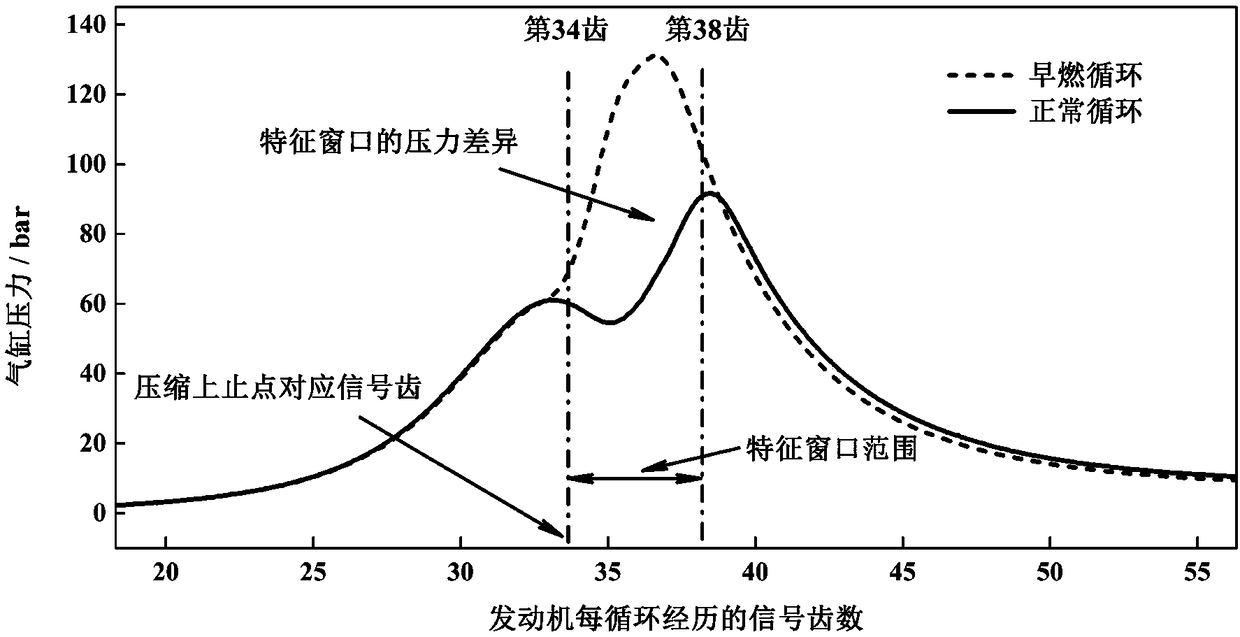

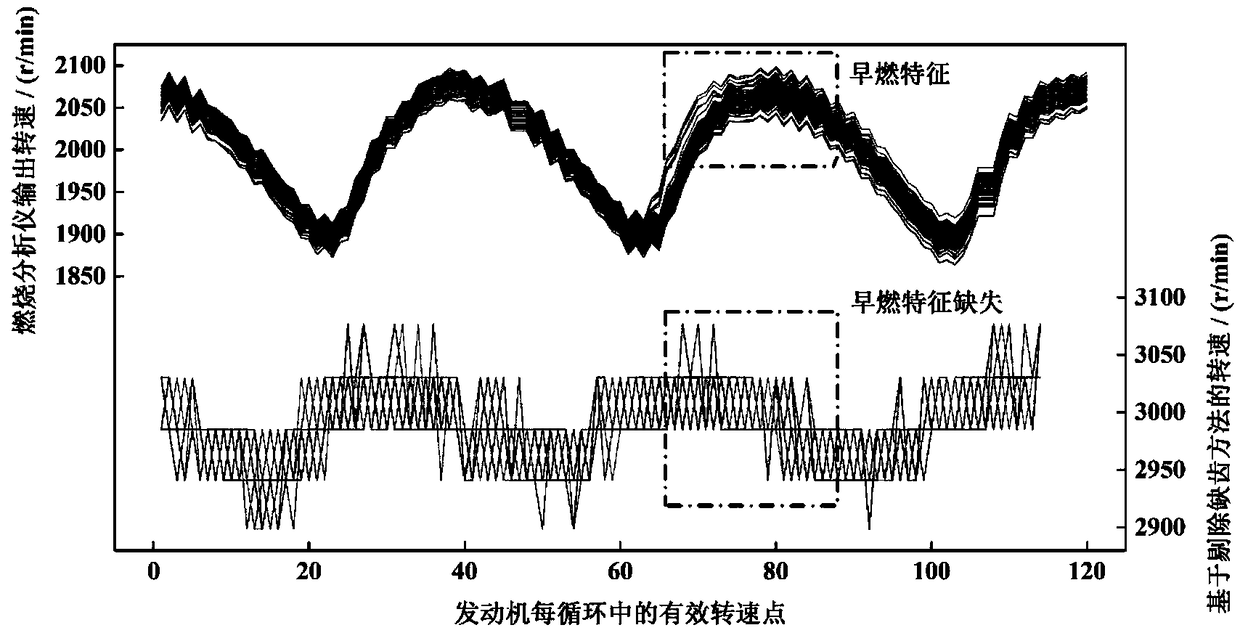

[0046] This embodiment provides a method for detecting pre-ignition of an internal combustion engine, and the layout of the detection device is as follows figure 1As shown, the original signal of the instantaneous speed of the flywheel ring gear 2 in the internal combustion engine 1 is first obtained through the 58-tooth speed sensor 3, and then the original signal of the instantaneous speed is preprocessed to obtain the instantaneous speed containing abnormal combustion information, and then the instantaneous speed Perform first-order derivation to obtain the instantaneous angular acceleration, extract all the instantaneous angular accelerations in the feature window 8, and integrate to obtain the integral value, compare the integral value with the pre-ignition threshold of the detection window to determine whether it is pre-ignition, the algorithm Integrated in ECU5, if pre-ignition occurs, control strategy 6 is adopted to feed back to internal combustion engine 1;

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com