Terrazzo flooring vibration rolling device

A terrazzo and ground technology, which is applied in the direction of architecture and building structure, can solve the problems of poor construction quality, increased labor, time-consuming and labor-intensive, etc., and achieve the effect of improving construction quality, reducing labor intensity, and uniform grouting stone particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

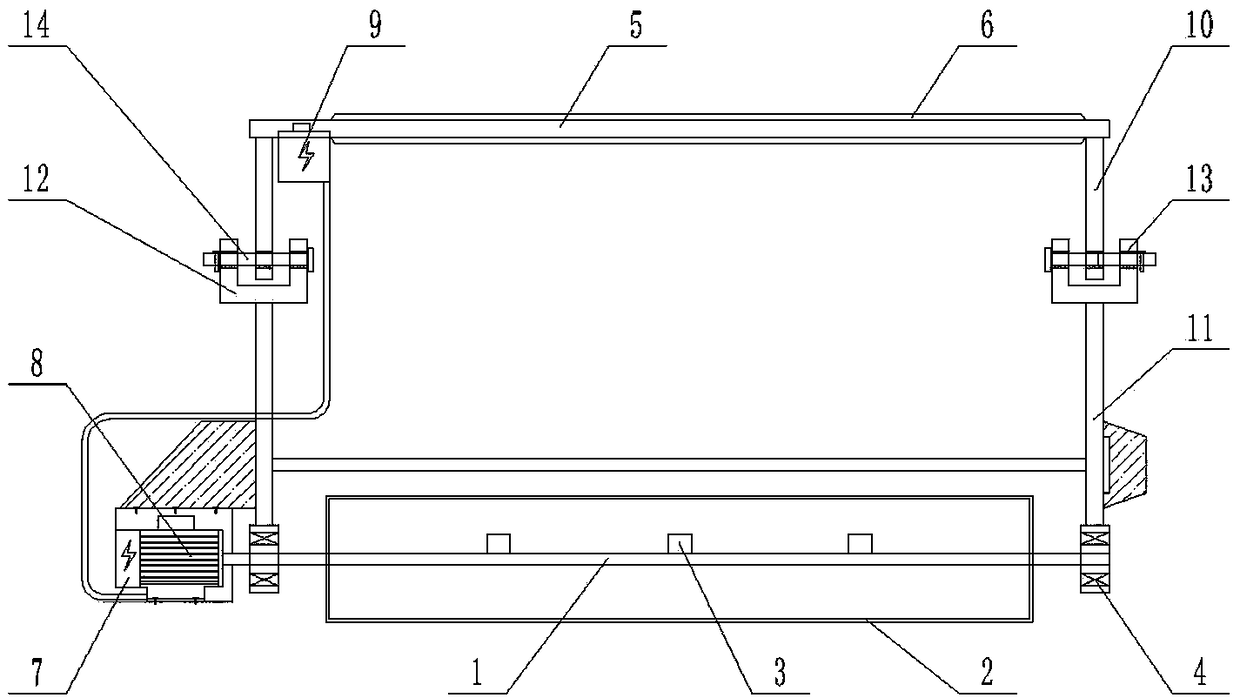

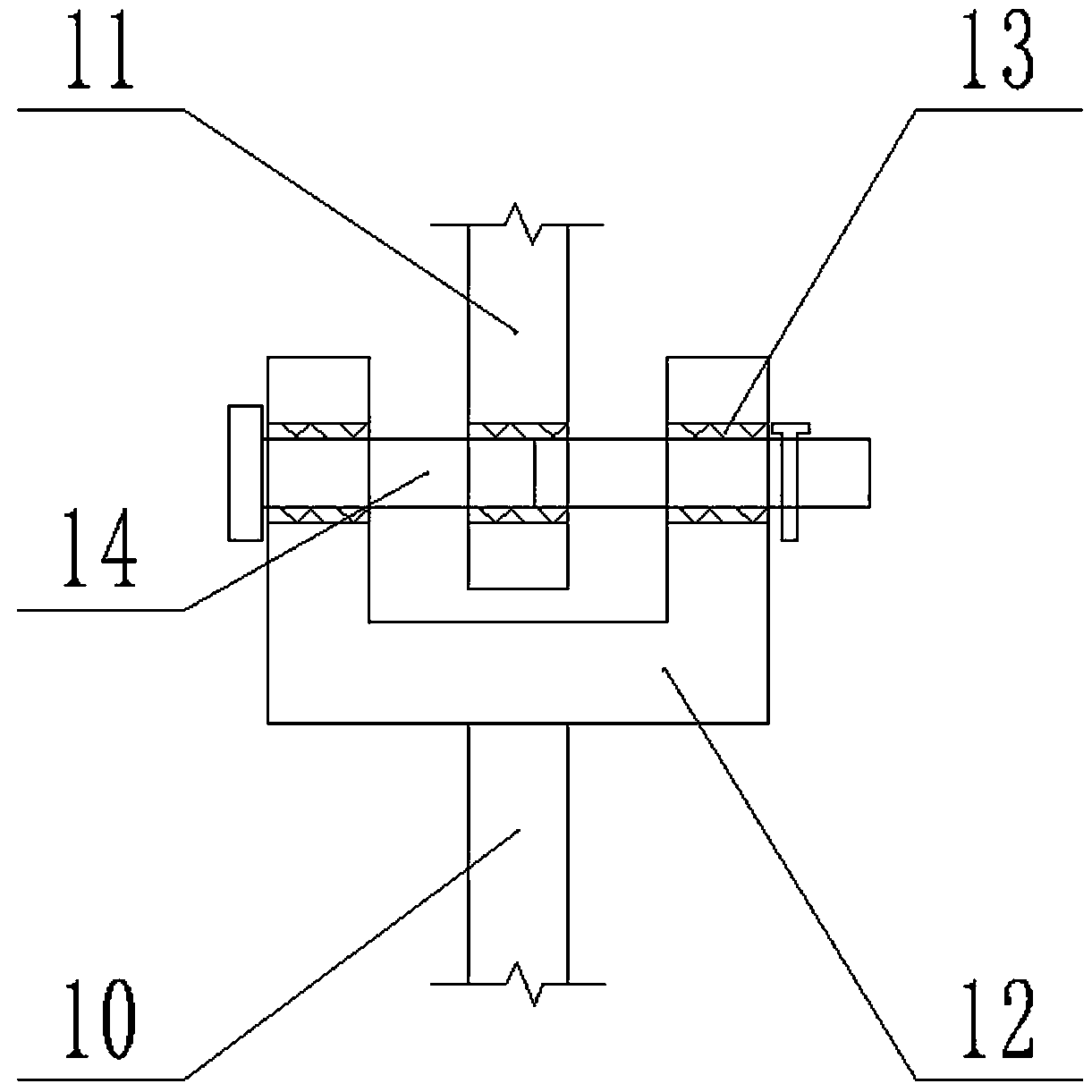

[0016] A terrazzo ground vibratory rolling device, comprising a roller shaft 1, a galvanized cylindrical cylinder 2 fixed to the roller shaft 1, a plurality of semicircular eccentric blocks 3 located in the galvanized cylindrical cylinder 2 are fixed on the roller shaft 1, the roller shaft 1 Bearings 4 located on the left and right sides of the galvanized cylindrical tube 2 are arranged on the shaft 1, support rods are fixed on the outer cylindrical surface of the bearing 4, and a tie rod 5 fixed to the two support rods is arranged between the upper ends of the two support rods. A rubber insulating sleeve 6 is arranged on the outer cylindrical surface of the outer cylinder, and a motor cover 7 is fixed on the support rod on the left side. The motor cover 7 is provided with a vibration motor 8 whose output shaft is connected to the roller shaft 1. The vibration motor 8 is connected with The reversing switch 9 that is fixed on pull bar 5 one ends.

[0017] The support bar is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com