Flue gas exhaust pipe and pipeline support

A technology for exhaust pipes and pipe supports, which is applied in the direction of pipe supports, vertical pipes, pipes/pipe joints/fittings, etc., which can solve the problems of long construction period and inconvenient installation of smoke exhaust pipes and pipe supports, and achieve simple adjustment methods Fast and convenient, easy to install, easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

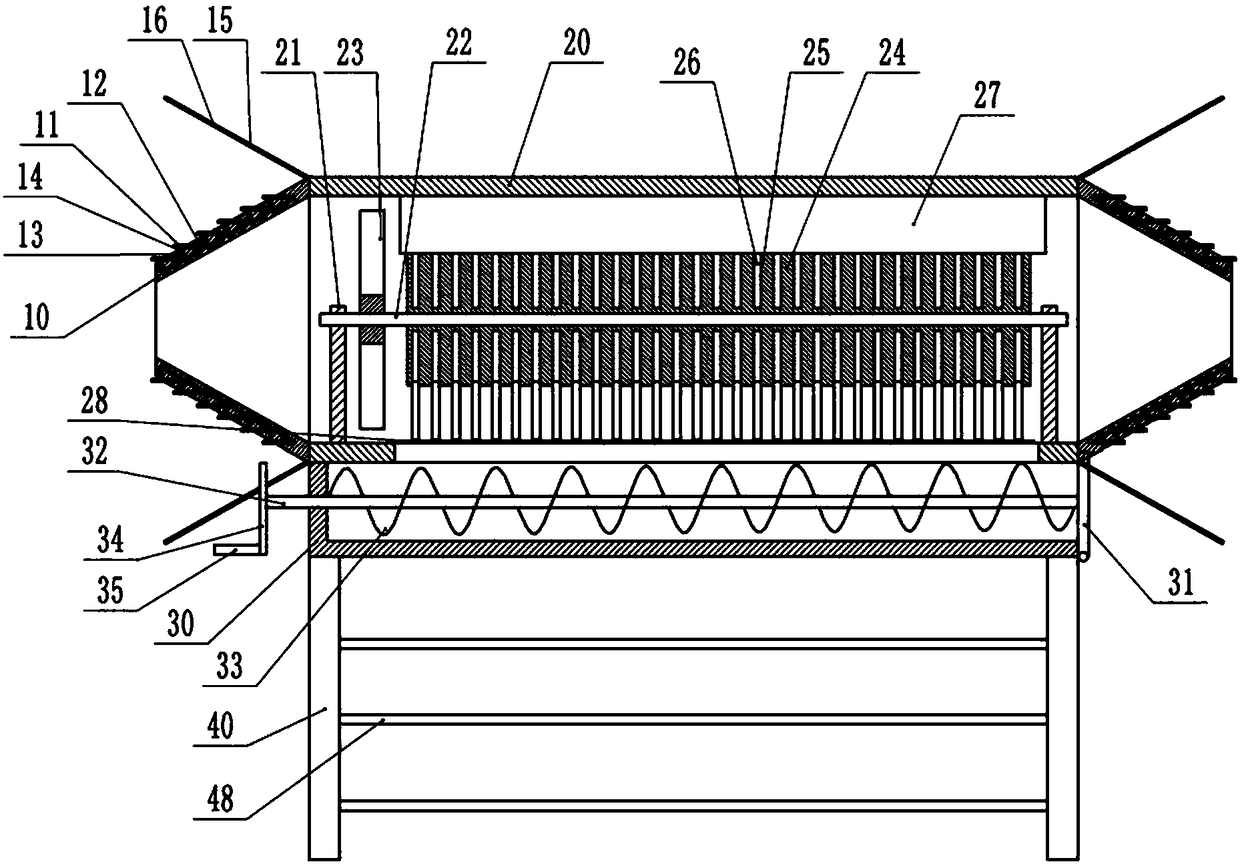

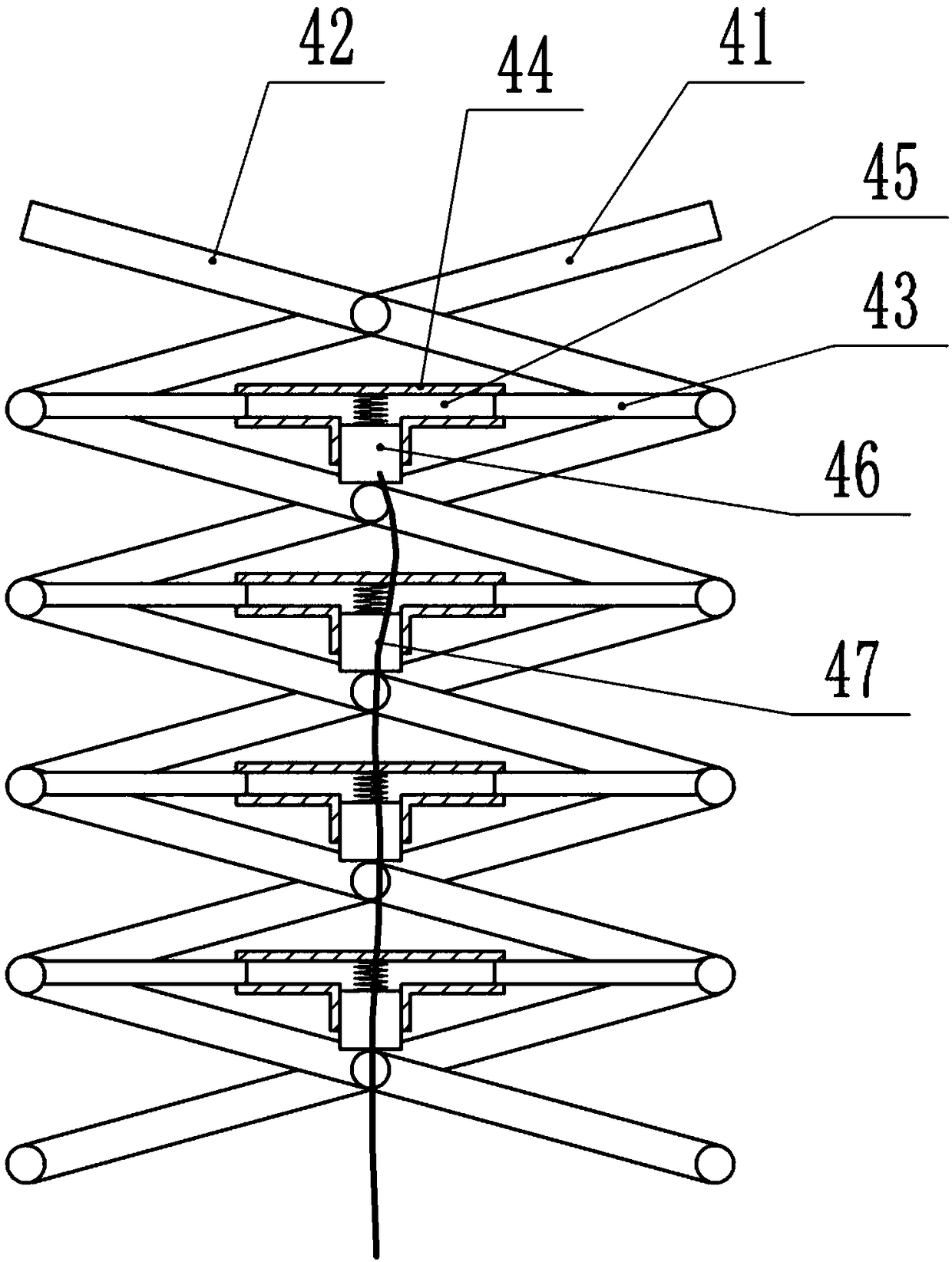

[0027] The reference signs in the drawings of the description include: connecting pipe 10, plug rod 11, cavity 12, ejector rod 13, first magnetic block 14, fixing plate 15, second magnetic block 16, smoke exhaust pipe 20, support plate 21 , Shaft 22, impeller 23, roller 24, sliding cavity 25, sliding rod 26, scraper 27, magnetic strip 28, dust collecting pipe 30, door 31, horizontal shaft 32, spiral conveying blade 33, turntable 34, handle 35. Telescopic unit 40, first pole 41, second pole 42, cross bar 43, T-shaped bar 44, T-shaped cavity 45, pull rod 46, control rope 47, connecting rod 48.

[0028] Such as figure 1 , figure 2 As shown, the smoke exhaust pipe and the pipe support include the smoke exhaust pipe 20, the connecting pipe 10 is installed on both sides of the smoke exhaust pipe 20, and the outside of the smoke exhaust pipe 20 is fixed on the pipe support; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com