Alternative grouting method for steel-structure column feet

A steel structure and column foot technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems that affect the safety of the structure, the load is large, and the inability to fill densely, etc., to achieve the effect of stable structure and densely poured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

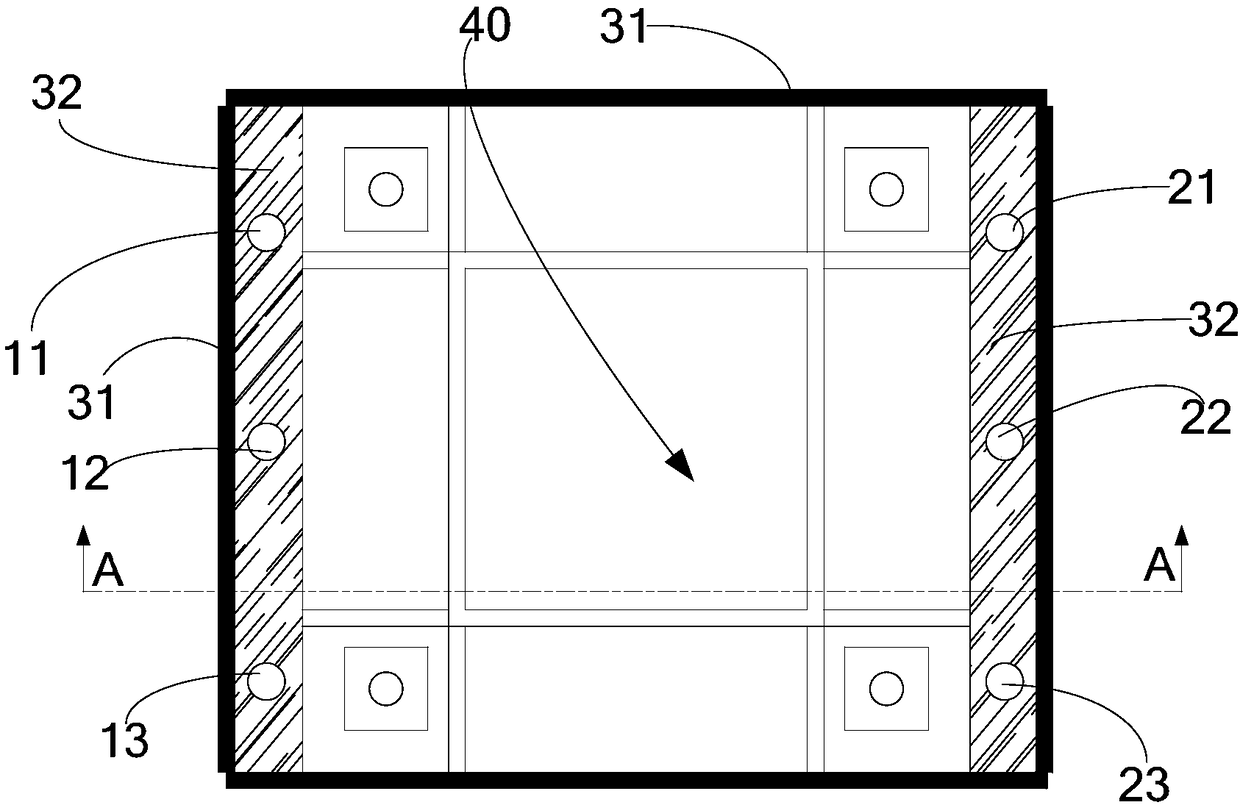

[0026] In order to provide a more compact grouting method for steel structure column feet and ensure a more stable and safe structure, the present invention provides an alternate grouting method for steel structure column feet.

[0027] The preferred embodiment of the steel structure column base alternate grouting method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

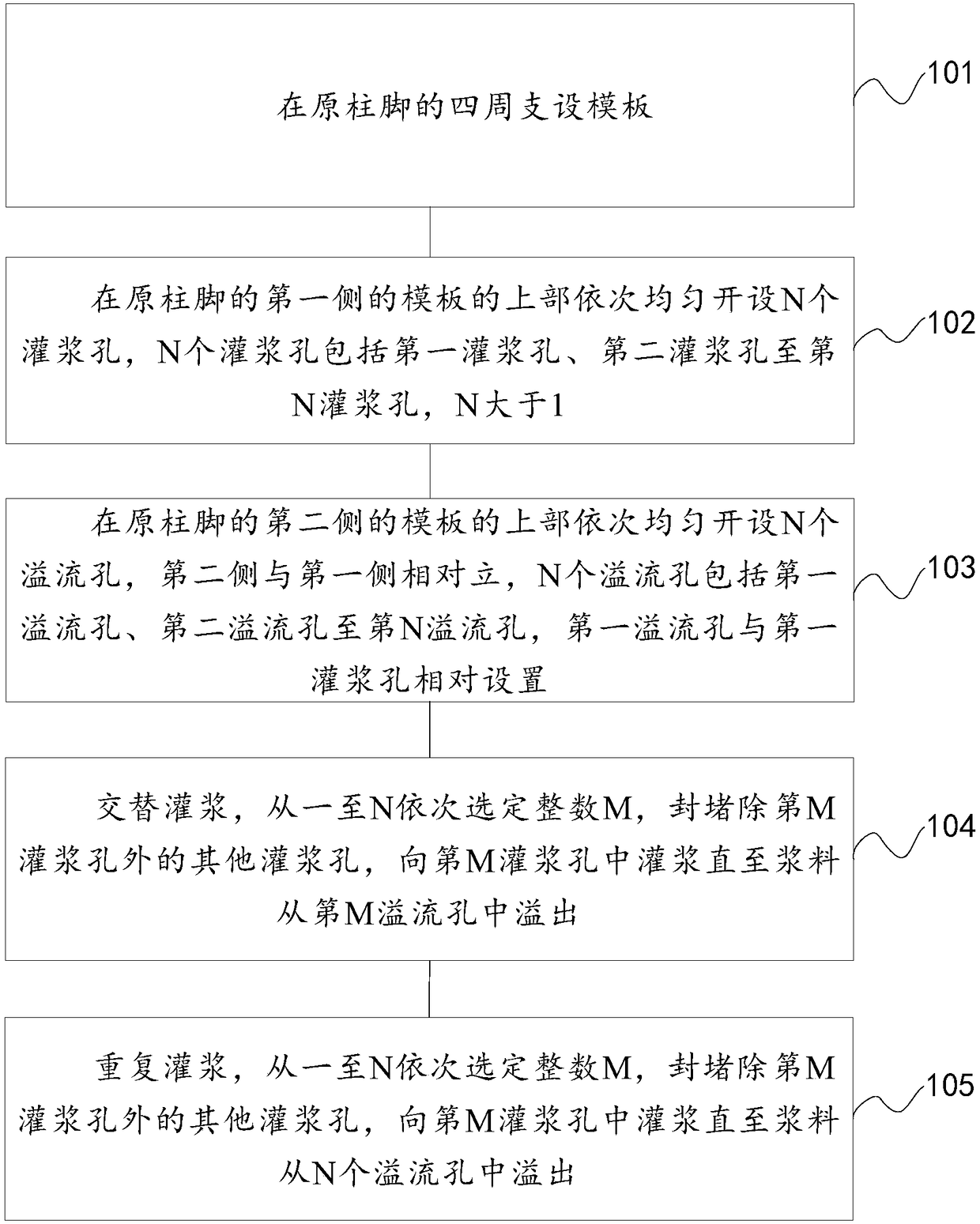

[0028] combine figure 1 As shown, the alternate grouting method for steel structure column feet of the present invention comprises steps:

[0029] Step 101: supporting formwork around the original column foot;

[0030] Step 102: Open N grouting holes evenly in sequence on the upper part of the formwork on the first side of the original column base, and the N grouting holes include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com