Box-lead viscoelastic composite energy dissipator

A technology of viscoelasticity and energy dissipation, which is applied in the field of square frame-lead viscoelastic composite energy dissipation, which can solve the problems of low initial stiffness and yield force, small energy dissipation capacity, etc., achieve large initial stiffness and maintain elastic recovery force , the effect of high fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

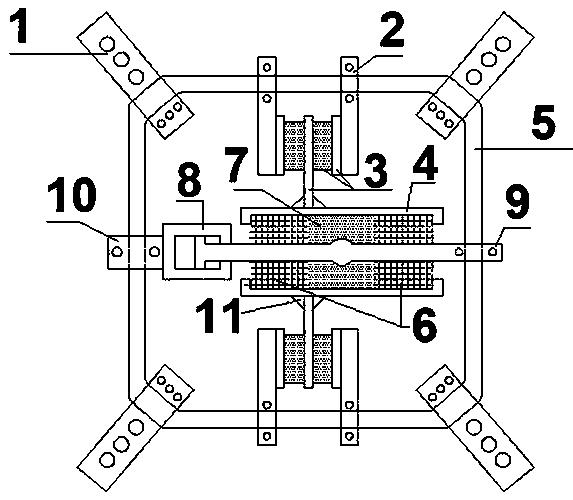

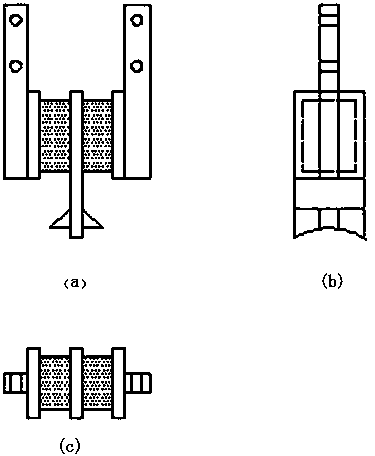

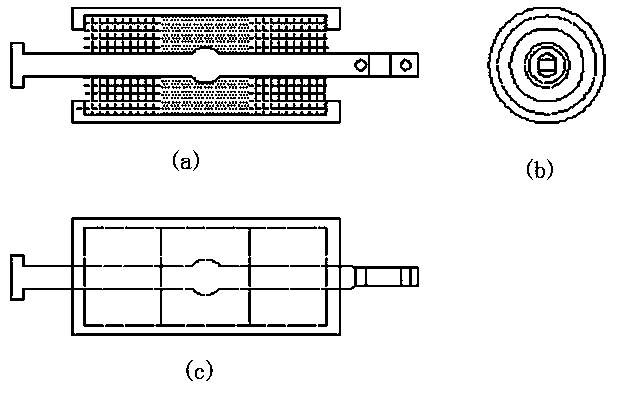

[0028] Embodiment 1: as figure 1 As shown, it is an embodiment of a square frame-lead viscoelastic composite energy dissipation device of the present invention, which mainly includes a connecting plate 1, a lead shearing element connecting plate 2, a lead shearing element 3, a thick-walled cylinder 4, a Energy block 5, viscoelastic material 6, lead core 7, central shaft sliding cylinder 8, central shaft 9, central shaft sliding cylinder connecting plate 10, triangular prism support 11.

[0029]Firstly, the square frame-lead viscoelastic composite energy dissipator is placed in the middle of the beam-column support with X-shaped support. The energy-dissipating frame 5 and its internal components are connected through a connecting plate, and the connection method is welding, and additionally add two upper and lower bolts and fixation positions. The energy dissipation frame 5 is connected with the external support through four connecting plates 1 . The lead shear element 3 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com