Special softener for bio-enzyme pulping and preparation method thereof

A softener and bio-enzyme technology, which is applied in the use of microorganism/enzyme cellulose treatment, textiles, papermaking, papermaking, etc., can solve the problem of increased wear of screw shafts, blade screen frames, anti-skid strips, and increased loss of wood chips and straw fibers. Large size, poor prepreg effect, etc., to achieve the effects of increasing spreadability, reducing energy consumption for refining, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

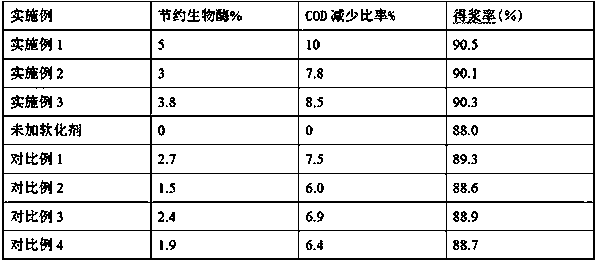

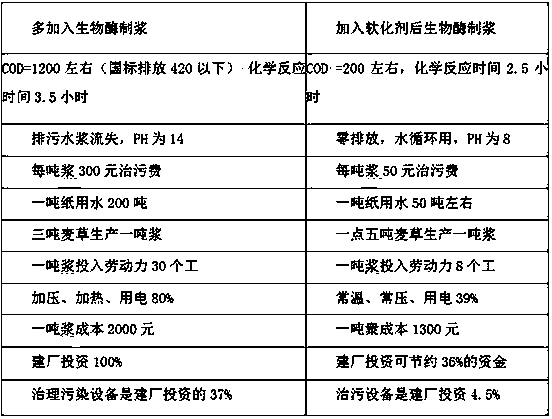

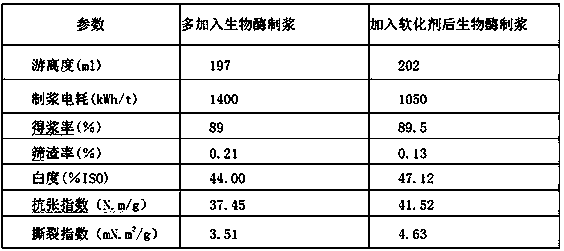

Examples

Embodiment 1

[0039] A special softener for biological enzyme pulping, which is composed of the following components by weight:

[0040] Penetrant BS, liquid, specific gravity 1.02, 6 parts;

[0041] Dioctyl sulfosuccinate sodium salt, 3 parts;

[0042] Isomeric alcohol polyoxyethylene ether, 7 parts;

[0043] Add O, liquid, specific gravity of 0.89, 18 parts;

[0044] Fatty alcohol polyoxyethylene ether, 2~10 ether, liquid, specific gravity 0.97, 20 parts;

[0045] Sodium alkyl sulfonate, liquid, specific gravity 1.06, 25 parts;

[0046] Fatty acid diethanolamide, 2.6 parts;

[0047] Sodium hexametaphosphate, 0.3 parts;

[0048] Sulfamic acid, 0.8 parts;

[0049] Sodium citrate, 2 parts;

[0050] Water, 15 parts.

[0051] The preparation method of the softening agent includes the following steps:

[0052] (1) Heat the water to 60°C, add Pingping O and fatty alcohol polyoxyethylene ether, heat to 72°C, and stir for 1.5 hours;

[0053] (2) Add sodium alkyl sulfonate and stir for 50 minutes; add osmotic agent B...

Embodiment 2

[0056] A special softener for biological enzyme pulping, which is composed of the following components by weight:

[0057] Penetrant BS, liquid, specific gravity 1.02, 4 parts;

[0058] Dioctyl sulfosuccinate sodium salt, 2 parts;

[0059] Isomeric alcohol polyoxyethylene ether, 6 parts;

[0060] Add O, liquid, specific gravity 0.89, 15 parts;

[0061] Fatty alcohol polyoxyethylene ether, 2~10 ether, liquid, specific gravity 0.97, 15 parts;

[0062] Sodium alkyl sulfonate, liquid, specific gravity 1.06, 40 parts;

[0063] Fatty acid diethanolamide, 2 parts;

[0064] Sodium hexametaphosphate, 0.5 parts;

[0065] Sulfamic acid, 0.5 parts;

[0066] Sodium citrate, 1 part;

[0067] Water, 14 parts.

[0068] The preparation method of the softening agent includes the following steps:

[0069] (1) Heat water to 55°C, add Pingping O and fatty alcohol polyoxyethylene ether, heat to 70°C, and stir for 1 hour;

[0070] (2) Add sodium alkyl sulfonate and stir for 40 minutes; add penetrant BS, dioctyl sulfos...

Embodiment 3

[0073] A special softener for biological enzyme pulping, which is composed of the following components by weight:

[0074] Penetrant BS, liquid, specific gravity 1.02, 10 parts;

[0075] Dioctyl sulfosuccinate sodium salt, 4 parts;

[0076] Isomeric alcohol polyoxyethylene ether, 8 parts;

[0077] Add O, liquid, specific gravity of 0.89, 15 parts;

[0078] Fatty alcohol polyoxyethylene ether, 2~10 ether, liquid, specific gravity 0.97, 15 parts;

[0079] Sodium alkyl sulfonate, liquid, specific gravity 1.06, 21 parts;

[0080] Fatty acid diethanolamide, 3 parts;

[0081] Sodium hexametaphosphate, 1 part;

[0082] Sulfamic acid, 1.0 part;

[0083] Sodium citrate, 5 parts;

[0084] Water, 17 parts.

[0085] The preparation method of the softening agent includes the following steps:

[0086] (1) Heat the water to 65°C, add PingPing O and fatty alcohol polyoxyethylene ether, heat to 75°C, and stir for 1 to 2 hours;

[0087] (2) Add sodium alkyl sulfonate and stir for 60 minutes; add penetrant BS, dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com