Preliminary processing method of flax stocks

A flax, to-be-processed technology, applied in textile and papermaking, mechanical treatment, fiber mechanical separation, etc., can solve the problems of poor quality, low rate of hemp, low safety, etc. The effect of high rate and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

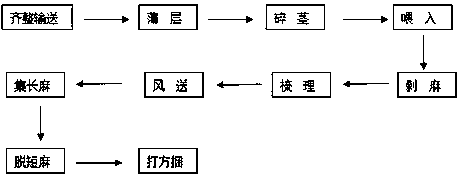

[0018] As shown in the accompanying drawings, the present invention provides a method for primary processing of dried flax stems, comprising the following steps.

[0019] 1 Neat conveying: The dried flax stems to be processed after the rain and dew retting are conveyed neatly and simultaneously by machinery, that is, the dried flax stems with uneven ends are neatly gathered in the middle of the conveyor belt, and the neat dried flax stems are then transported to in the TLC machine.

[0020] 2 Thin layer: The neat dried flax stem described in step 1 is subjected to mechanical thin layer treatment, so that the thickness of the dried flax stem is consistent.

[0021] 3 broken stems: crush the dried flax stems described in step 2 with a stem crusher to crush their xylem; the dried flax stems after being neatly and thinly layered are neat at both ends and consistent in thickness, and then continuously enter the stem crusher When crushing the stems, it can greatly improve the effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com