Pressing type efficient soybean oil production device

A production device and soybean oil technology, which is applied in the direction of fat oil/fat production, fat production, fat oil/fat refining, etc., can solve the problems of long soybean oil production cycle, unfavorable large-scale production, and poor coordination, etc. Oil time, transfer time is short, the effect of convenient production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

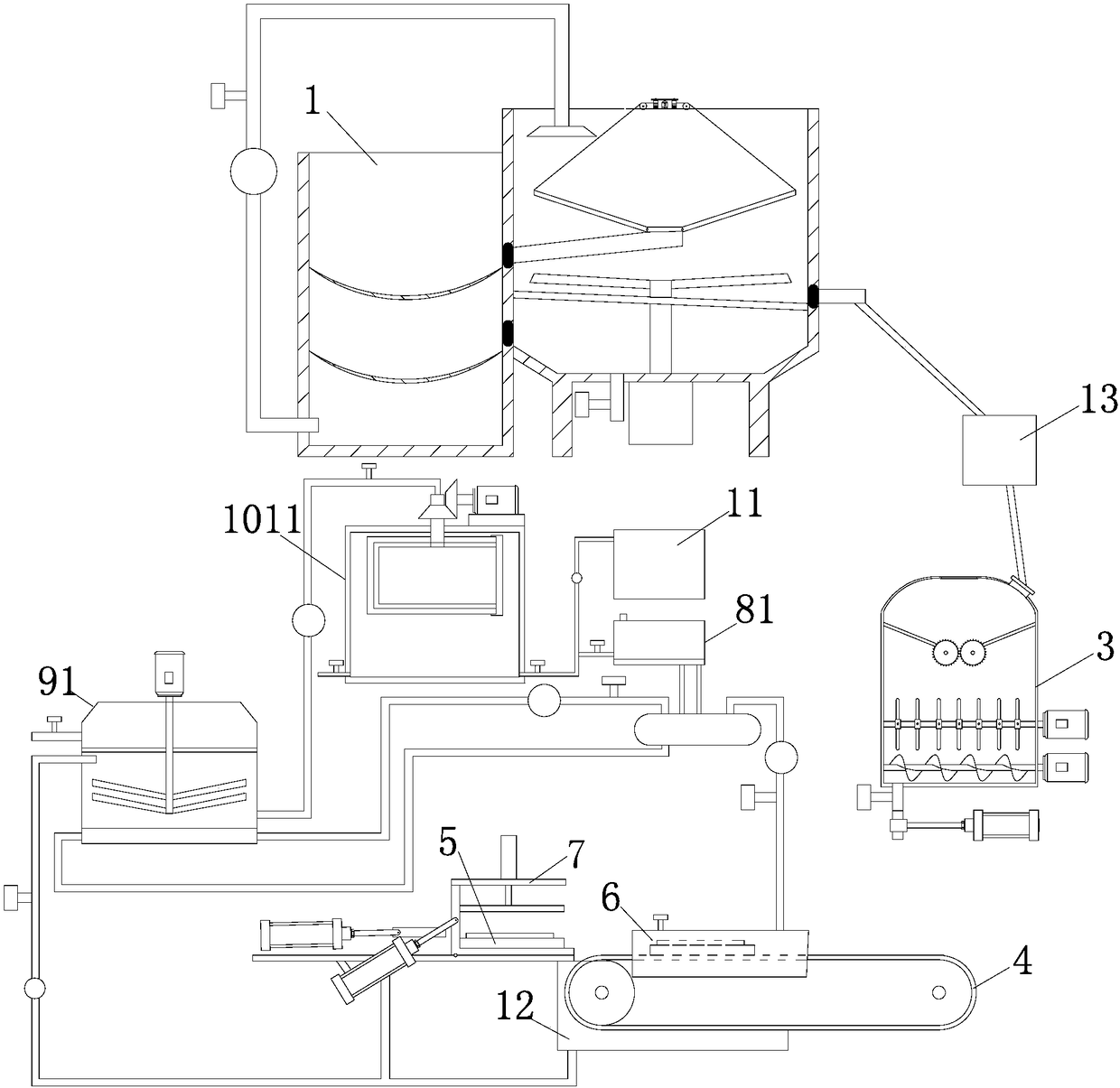

[0040] Such as figure 1 Shown, the soybean oil finishing device that the present invention proposes, this device comprises in order of process flow sequence: soybean pretreatment system, soybean pressing system and centrifugation system; Said soybean pretreatment system includes cleaning unit 1 and crushing unit 3 , the cleaning unit 1 is used to remove light impurities, grit and dust mixed in soybeans, and the crushing unit 3 is used to crush the cleaned soybeans to obtain soybean dregs; the soybean pressing system It is used for pressing soybean dregs; the centrifugal separation system is used for oil-water separation of crude oil obtained after pressing.

[0041] The soybean squeezing system includes a primary squeezing unit and a secondary squeezing unit, and the primary squeezing unit 7 includes a squeezing table 76, a support, a turning cylinder 75, a pressing hydraulic cylinder 74 and a pressing plate 73; Plate 71 and two horizontal plates 72 arranged in parallel up an...

Embodiment 2

[0056] refer to Figure 8 , The difference between this embodiment and Embodiment 1 is that a limit mechanism is provided on the end side of the movement stroke of the slider 23, and the limit mechanism includes a limit plate 27 and a limit cylinder 26, and the limit plate 27 and the pushing plate 25 are respectively located on both sides of the slider 23, the upper surface of the limiting plate 27 is located below the upper surface of the loading plate 5, the limiting plate 27 and the limiting cylinder 26 The piston end is connected, and is driven by the limiting cylinder 26 to move horizontally, and the moving direction of the limiting plate 27 is parallel to the moving direction of the pushing plate 25 .

[0057] After the primary pressing unit finishes pressing the soybean dregs, the piston end of the limiting cylinder 26 protrudes outwards, and drives the limiting plate 27 to move horizontally until the limiting plate 27 abuts against the loading plate 5 . Because the li...

Embodiment 3

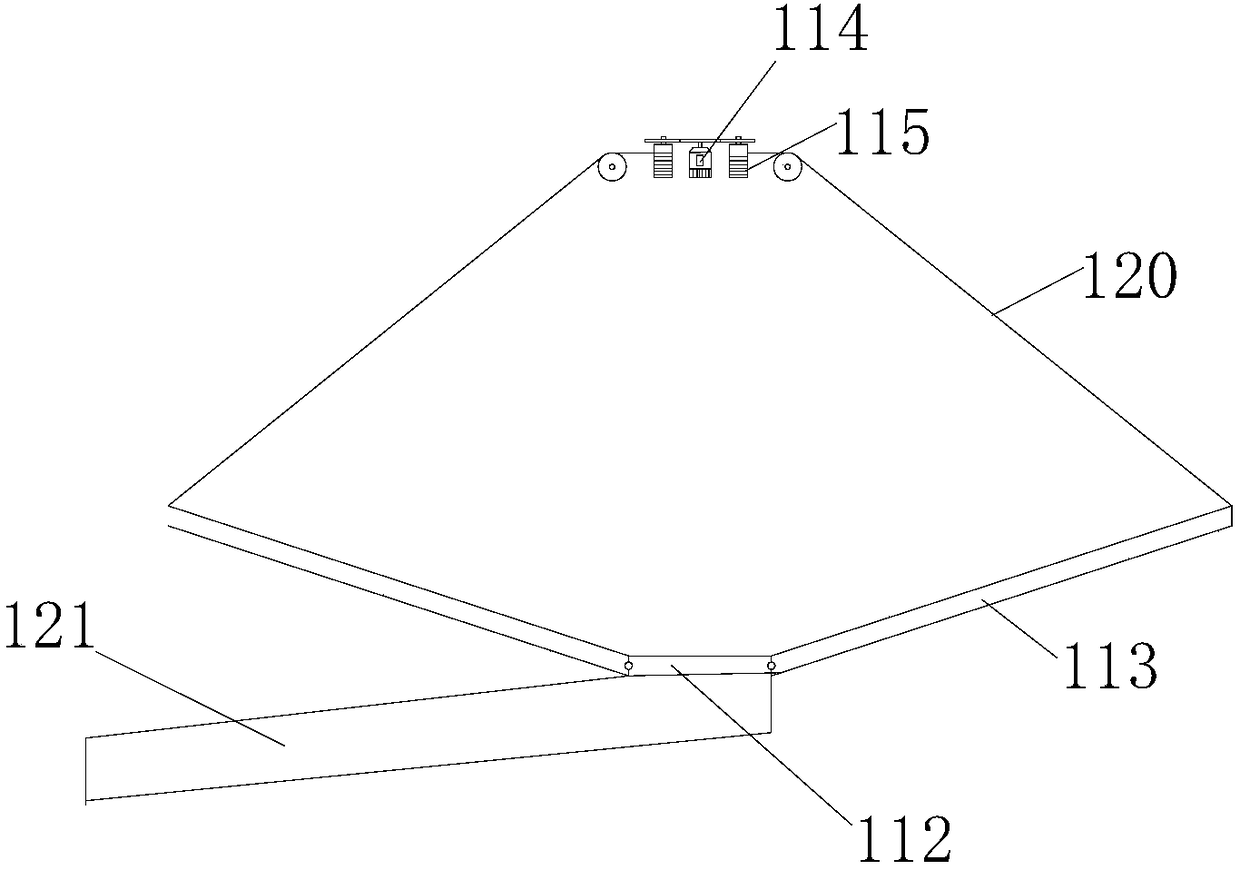

[0059] refer to figure 2 The difference between this embodiment and Embodiment 1 is that the cleaning unit 1 includes a cleaning tank 111, a reservoir 101, and an impurity removal mechanism; the reservoir 101 is filled with clear water, and the reservoir 101 is connected with The upper filter 102, the water outlet at the bottom of the reservoir 101 communicates with the cleaning tank 111 through the outlet pipe; the cleaning tank 111 is provided with a screen 122 and a stirring mechanism, and the screen 122 is located at the outlet Below the outlet of the water pipe, the stirring mechanism includes a stirring motor 117 and a stirring paddle 116. The bottom of the reservoir 111 is provided with an insertion port, and a waterproof bearing is installed in the insertion port. The output shaft of the stirring motor 117 is passed through the In the waterproof bearing, one end thereof extends into the cleaning tank 111, and is fitted with a stirring shaft. The screen 122 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com