Method for improving luminescence performance of aluminate long-afterglow material by platinum

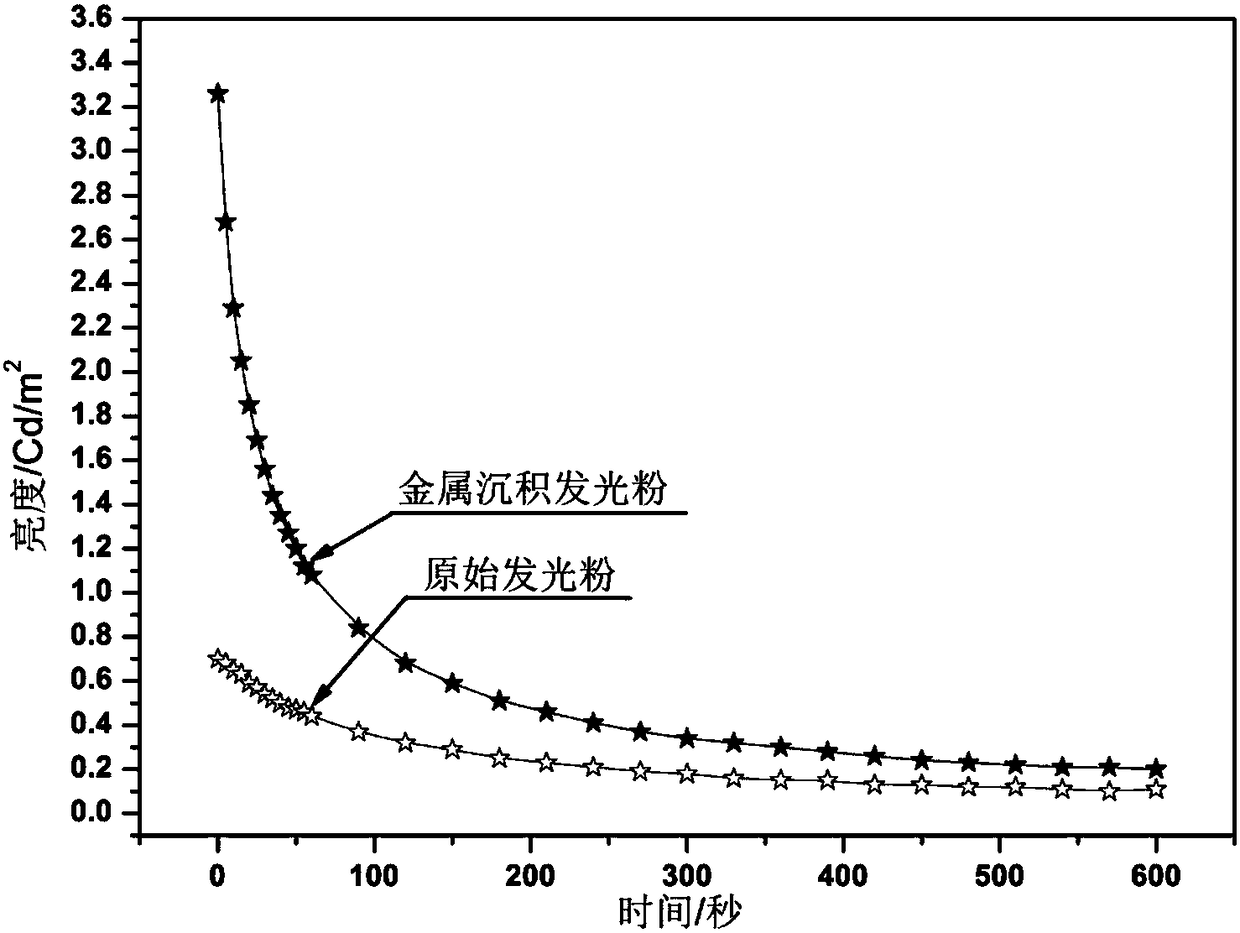

A long afterglow material and long afterglow luminescence technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of unobvious afterglow performance, large particles, unfavorable afterglow performance of luminescent powder, etc., and achieve high long afterglow luminescence performance, synthetic The effect of simple process and convenient industrial mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

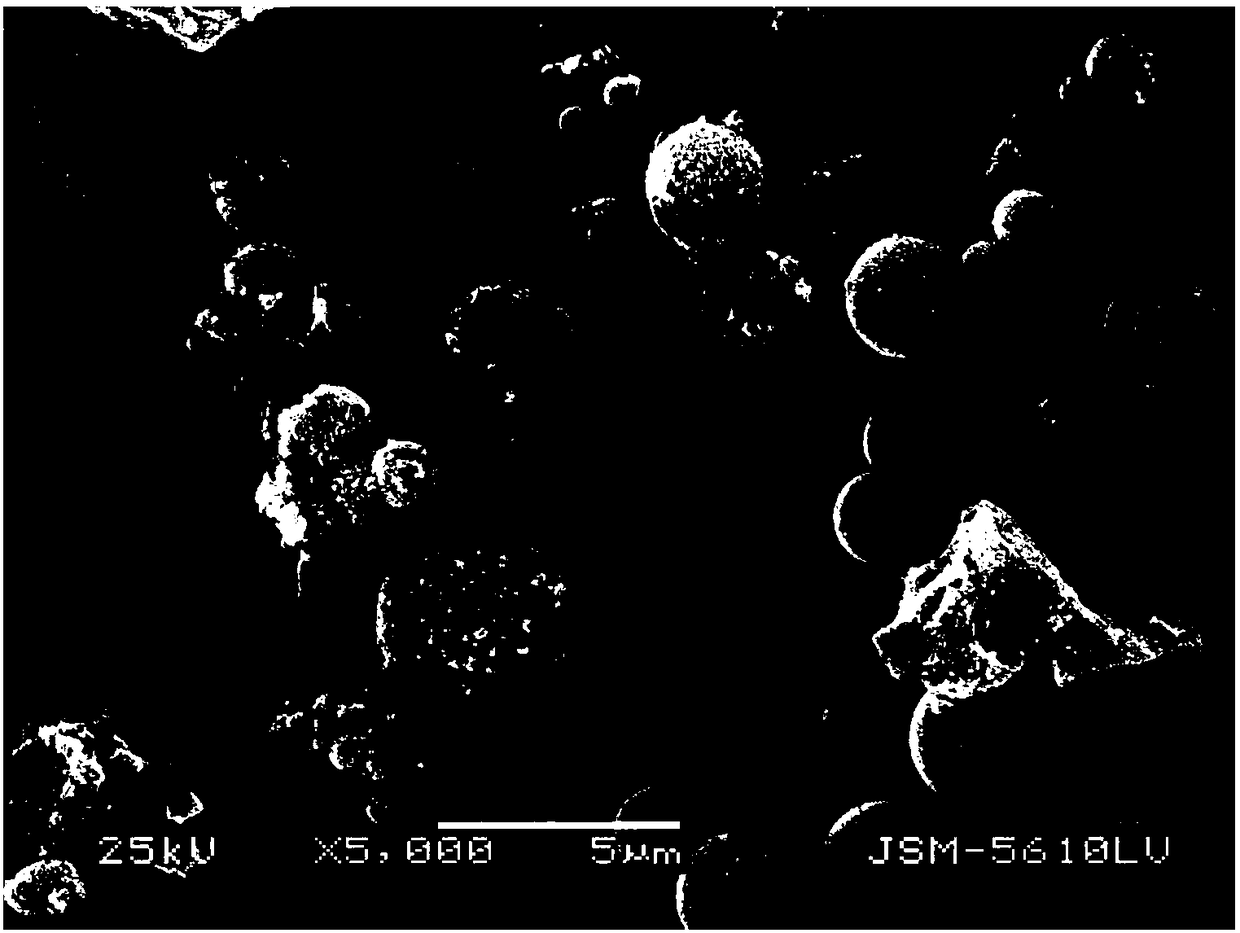

[0032] Step 1. Using carbon spheres as templates, spherical Sr was obtained by coprecipitation-hydrothermal method 4 al 14 o 25 :Eu 2+ , Dy 3+ precursor, and then sintered in a reducing atmosphere for 2 h at a firing temperature of 900 °C to obtain spherical Sr 4 al 14 o 25 :Eu 2+ , Dy 3+ luminous powder;

[0033] Step 2, Spherical Sr 4 al 14 o 25 :Eu 2+ , Dy 3+ Pour the luminescent powder into alcohol, so that the alcohol submerges the luminescent powder, sonicate in an ultrasonic instrument for 7 minutes, filter after the ultrasonic is completed, and dry in an oven at 150°C for 16 minutes;

[0034] Step 3, the H 2 PtCl 6 Dissolved in alcohol to form a homogeneous solution, where H 2 PtCl 6 The molar concentration is 0.01mmol L -1 ;

[0035] Step 4, 2ml of H obtained in step 3 2 PtCl 6 Solution, acetic acid and alcohol are mixed according to 1:4:500 to form a uniform solution;

[0036] Step 5: Pour 0.2 g of the luminescent powder obtained in step 2 into ...

Embodiment 2

[0042] Step 1. Using carbon spheres as templates, spherical Sr was obtained by coprecipitation-hydrothermal method 4 al 14 o 25 :Eu 2+ , Dy 3+ precursor, and then sintered in a reducing atmosphere for 2 h at a firing temperature of 1000 °C to obtain spherical Sr 4 al 14 o 25 :Eu 2+ , Dy 3+ luminous powder;

[0043] Step 2, Spherical Sr 4 al 14 o 25 :Eu 2+ , Dy 3+ Pour the luminescent powder into alcohol, so that the alcohol submerges the luminescent powder, sonicate in the ultrasonic instrument for 10 minutes, filter after the ultrasonic is completed, and dry in an oven at 135°C for 20 minutes;

[0044] Step 3, the H 2 PtCl 6 Dissolved in alcohol to form a homogeneous solution, where H 2 PtCl 6 The molar concentration is 0.1mmol L -1 ;

[0045] Step 4, 2ml of H obtained in step 3 2 PtCl 6 Solution, acetic acid and alcohol are mixed according to 1:7:500 to form a uniform solution;

[0046] Step 5: Pour 1 g of the luminescent powder obtained in step 2 into ...

Embodiment 3

[0049] Step 1. Using carbon spheres as templates, spherical Sr was obtained by coprecipitation-hydrothermal method 4 al 14 o 25 :Eu 2+ , Dy 3+ precursor, and then sintered in a reducing atmosphere for 3 h at a firing temperature of 1100 °C to obtain spherical Sr 4 al 14 o 25 :Eu 2+ , Dy 3+ luminous powder;

[0050] Step 2, Spherical Sr 4 al 14 o 25 :Eu 2+ , Dy 3+ Pour the luminescent powder into alcohol, so that the alcohol submerges the luminescent powder, sonicate in an ultrasonic instrument for 8 minutes, filter after the ultrasonic is completed, and dry in an oven at 100°C for 19 minutes;

[0051] Step 3, the H 2 PtCl 6 Dissolved in alcohol to form a homogeneous solution, where H 2 PtCl 6 The molar concentration is 0.15mmol L -1 ;

[0052] Step 4, 1ml of H obtained in step 3 2 PtCl 6 Solution, acetic acid and alcohol are mixed according to 7:5:500 to form a uniform solution;

[0053] Step 5, pour 1g of the luminescent powder obtained in step 2 into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com