Preparation method of high-substituted etherified corn starch

A technology of corn starch and high degree of substitution is applied in the field of preparation of high degree of substitution etherified corn starch, which can solve problems such as low degree of substitution, and achieve the effects of low cost, reduced consumption and easy promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Weigh 10g of starch and dissolve it with 30ml of absolute ethanol, stir it with a glass rod and pour it into a 250ml three-neck flask, add 0.5wt% (relative to the quality of dry starch) nanocellulose, stir and mix for 0.5h, and adjust the temperature of the water bath to 50 ℃, add 16wt% NaOH for alkalinization for 0.5h, add 5wt% monochloroacetic acid solution (concentration is 70wt%) and join the three-necked flask, stop the etherification reaction after mechanical stirring for 4h, wash and centrifuge with methanol solution with a volume fraction of 80% Sodium chloride is not contained in the product (checked with silver nitrate aqueous solution), and the pH is adjusted to neutral with glacial acetic acid, and then the product is dried in an oven at 45° C. to obtain etherified starch in the form of white powder.

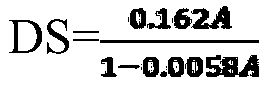

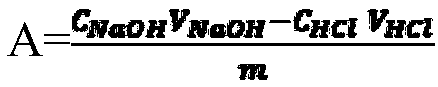

[0046] Measure the degree of substitution of the etherified product by acid titration, accurately weigh 0.5g of the sample, place it in a 50ml small beaker, ad...

Embodiment 2

[0058] Weigh 10g of starch and dissolve it with 30ml of absolute ethanol, stir it with a glass rod and pour it into a 250ml three-neck flask, add 3wt% (relative to the mass of dry starch) nanocellulose, stir and mix for 0.5h, and adjust the temperature of the water bath to 50°C , add 18wt% NaOH to alkalinize for 1h, add 5wt% monochloroacetic acid solution (concentration is 70wt%) and join into the there-necked flask, terminate the etherification reaction after mechanical stirring for 5h, wash and centrifuge to the product with a volume fraction of 80% methanol solution Sodium chloride is not contained in the product (tested with silver nitrate aqueous solution), and the pH is adjusted to neutral with glacial acetic acid, and then the product is dried in an oven at 45°C to obtain white powdery etherified starch.

[0059] The degree of substitution of the etherified product was determined to be 0.73 by acid titration.

Embodiment 3

[0061] Weigh 10g of starch and dissolve it with 30ml of absolute ethanol, stir it with a glass rod and pour it into a 250ml three-necked flask, add 5wt% (relative to the mass of dry starch) nanocellulose, stir and mix for 0.5h, and adjust the temperature of the water bath to 50°C , add 20wt% NaOH for alkalization for 2h, add 5wt% monochloroacetic acid solution (concentration is 70wt%) and join in the there-necked flask, stop the etherification reaction after mechanical stirring for 6h, wash and centrifuge to the product with 80% methanol solution by volume fraction Sodium chloride is not contained in the product (tested with silver nitrate aqueous solution), and the pH is adjusted to neutral with glacial acetic acid, and then the product is dried in an oven at 45°C to obtain white powdery etherified starch.

[0062] The degree of substitution of the etherified product was determined to be 0.81 by acid titration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com