Method for preparing green pervious concrete by using tailings

A permeable concrete and green technology, applied in the field of civil and construction materials, can solve the problems that affect the use and promotion of permeable concrete, cannot meet the requirements of high-performance pavement, and cannot meet the requirements of drainage, etc., to achieve significant superposition effect, crack resistance reduction, The effect of high early strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

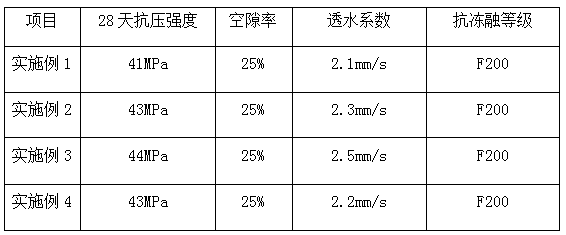

Examples

Embodiment 1

[0029] Raw materials (by weight):

[0030] 50 parts of aggregate, 20 parts of 52.5 Portland cement, 15 parts of ceramsite, 1 part of superplasticizer, 0.1 part of composite early strength agent, 0.1 part of composite retarder, 0.02 part of defoamer, and 0.02 part of air-entraining agent ;

[0031] The preparation method of green permeable concrete comprises the following steps:

[0032]S1. First add aggregate, 52.5 Portland cement, ceramsite, high-efficiency water reducer, defoamer and appropriate amount of water into the mixer and stir for 2-3 minutes, then add composite early strength agent, composite retarder and air-entraining Continue to stir the agent for 3-5 minutes, adjust the consistency of the mixture with an appropriate amount of water, put the stirred concrete into the mold for static pressure molding, demould after 24 hours, and obtain a permeable concrete body, the pressure is 1-2MPa, Static pressure time 15-20s;

[0033] S2. During curing, first spray the cur...

Embodiment 2

[0035] Raw materials (by weight):

[0036] 60 parts of aggregate, 25 parts of 52.5 Portland cement, 16 parts of ceramsite, 1.5 parts of superplasticizer, 0.2 part of composite early strength agent, 0.4 part of composite retarder, 0.05 part of defoamer, and 0.05 part of air-entraining agent ;

[0037] The preparation method of green permeable concrete comprises the following steps:

[0038] S1. First add aggregate, 52.5 Portland cement, ceramsite, high-efficiency water reducer, defoamer and appropriate amount of water into the mixer and stir for 2-3 minutes, then add composite early strength agent, composite retarder and air-entraining Continue to stir the agent for 3-5 minutes, adjust the consistency of the mixture with an appropriate amount of water, put the stirred concrete into the mold for static pressure molding, demould after 24 hours, and obtain a permeable concrete body, the pressure is 1-2MPa, Static pressure time 15-20s;

[0039] S2. During curing, first spray the...

Embodiment 3

[0041] Raw materials (by weight):

[0042] 65 parts of aggregate, 28 parts of 52.5 Portland cement, 18 parts of ceramsite, 1.8 parts of superplasticizer, 0.4 part of composite early strength agent, 0.8 part of composite retarder, 0.08 part of defoamer, and 0.08 part of air-entraining agent ;

[0043] The preparation method of green permeable concrete comprises the following steps:

[0044] S1. First add aggregate, 52.5 Portland cement, ceramsite, high-efficiency water reducer, defoamer and appropriate amount of water into the mixer and stir for 2-3 minutes, then add composite early strength agent, composite retarder and air-entraining Continue to stir the agent for 3-5 minutes, adjust the consistency of the mixture with an appropriate amount of water, put the stirred concrete into the mold for static pressure molding, demould after 24 hours, and obtain a permeable concrete body, the pressure is 1-2MPa, Static pressure time 15-20s;

[0045] S2. During curing, first spray the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com