Method for recycling and processing pickling waste liquid containing iron

A recovery treatment and pickling technology, applied in metallurgical wastewater treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of large sewage discharge, high cost, difficult recycling, etc., and achieve recycling, equipment The effect of low requirements and single processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

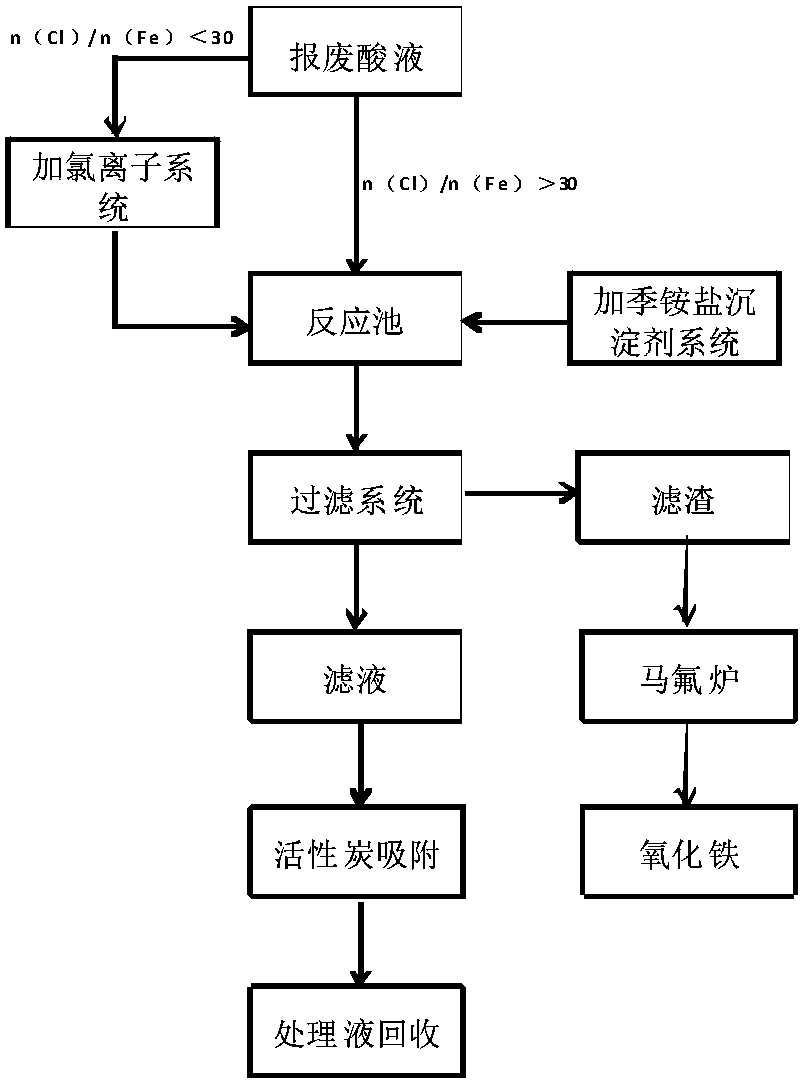

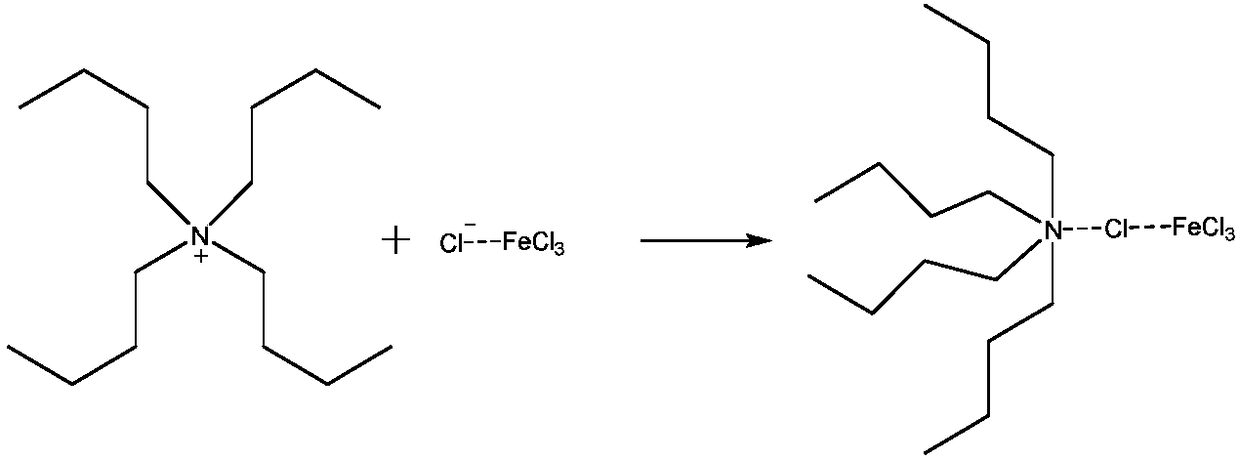

Problems solved by technology

Method used

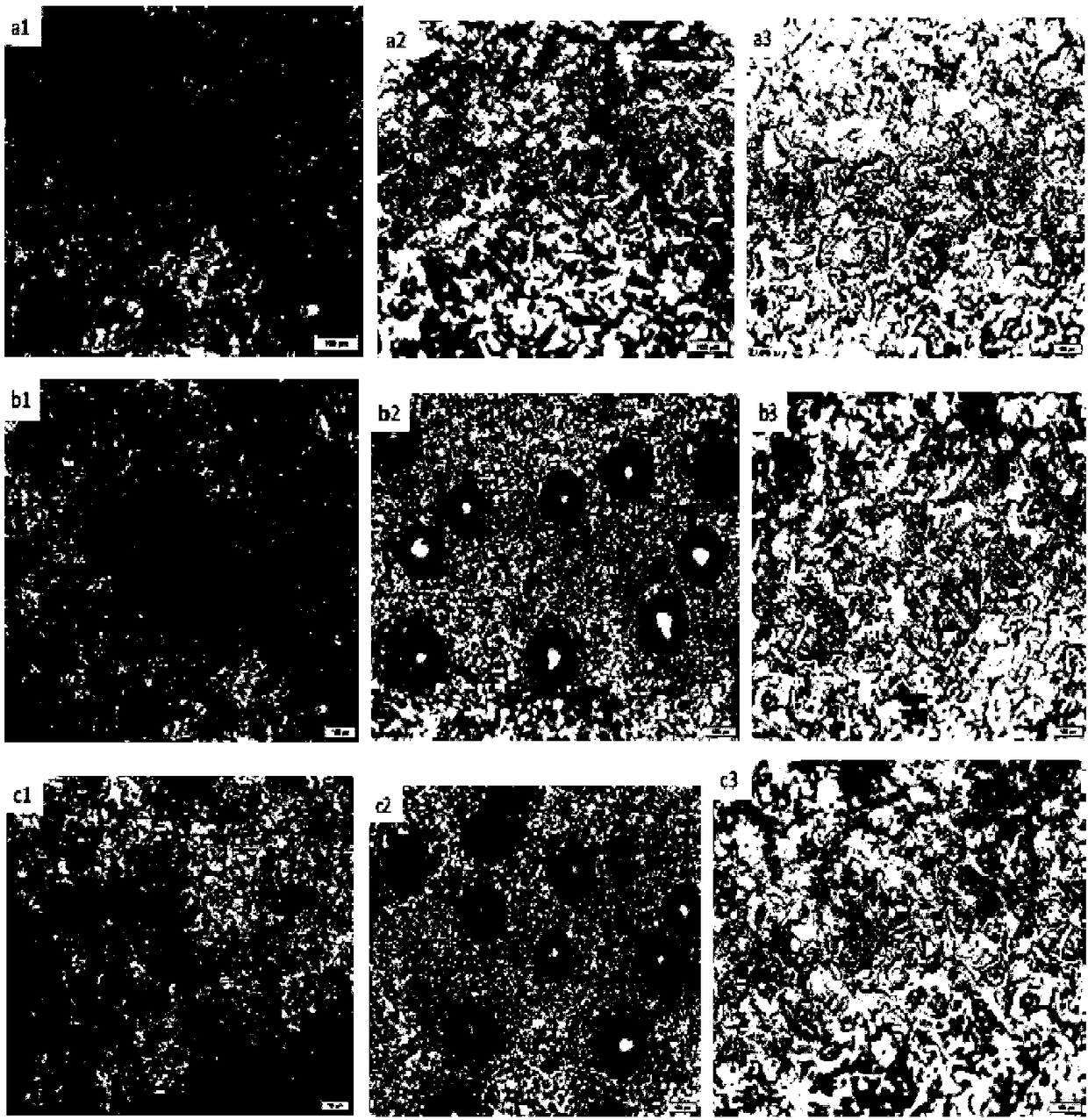

Image

Examples

Embodiment 1

[0038] Embodiment 1: the hydrochloric acid waste liquid recovery treatment that contains 5.6g / L iron ion 6mol / L

[0039]Treatment method: Add 1ml of 0.5mol / L tetrabutylammonium chloride solution to 5ml of waste hydrochloric acid solution containing 5.6g / L iron ion and 6mol / L, mix well and stir for 2 hours, yellow insoluble acid appears precipitation. After the mixture in the reaction tank was allowed to settle for 2 hours, it was subjected to suction filtration. Add 0.1 g of activated carbon to the filtrate for adsorption. The concentration of hydrochloric acid in the filtrate was measured to be 4.85 mol / L, and the removal rate of iron ions was 93.6%. It was recovered and used as a cleaning solution; the filter residue was roasted at 500°C for 5 hours to obtain iron oxide, which was recovered.

Embodiment 2

[0040] Embodiment 2: the hydrochloric acid waste liquid recovery treatment of the 6mol / L that contains 84g / L iron ion

[0041] Treatment method: Add 2.084g of tetrabutylammonium chloride to 5ml of waste hydrochloric acid solution containing 84g / L iron ion and 6mol / L, mix thoroughly for 2 hours, and a yellow insoluble acid-soluble precipitate appears. After the mixture in the reaction tank was allowed to settle for 2 hours, it was subjected to suction filtration. Add 0.1 g of activated carbon to the filtrate for adsorption. The concentration of hydrochloric acid in the filtrate was measured to be 4.56 mol / L, and the removal rate of iron ions was 99.3%. It was recovered and used as a cleaning solution; the filter residue was roasted at 500°C for 5 hours to obtain iron oxide, which was recovered.

Embodiment 3

[0042] Embodiment 3: the hydrochloric acid waste liquid recovery treatment of the 6mol / L that contains 5.6g / L iron ion

[0043] Treatment method: Add 1ml of 0.5mol / L tetrapropylammonium chloride solution to 5ml of waste hydrochloric acid solution containing 5.6g / L iron ion and 6mol / L, mix thoroughly for 2 hours, and a yellow insoluble acid-soluble precipitate appears . After the mixture in the reaction tank was allowed to settle for 5 hours, suction filtration was performed. Add 0.1 g of activated carbon to the filtrate for adsorption, the hydrochloric acid concentration in the filtrate was measured to be 4.89 mol / L, and the removal rate of iron ions was 48.1%, which was recovered and used as a cleaning solution; the filter residue was roasted at 500°C for 5 hours to obtain iron oxide, which was recovered.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com