Printing accuracy detection system

A technology of precision detection and detection device, applied in printing, printing device, metal processing and other directions, can solve the problems of reducing the processing quality and processing accuracy of invoices, unable to locate the function, etc., and achieve the effect of reducing speed difference and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further detailed explanation through specific implementation mode below:

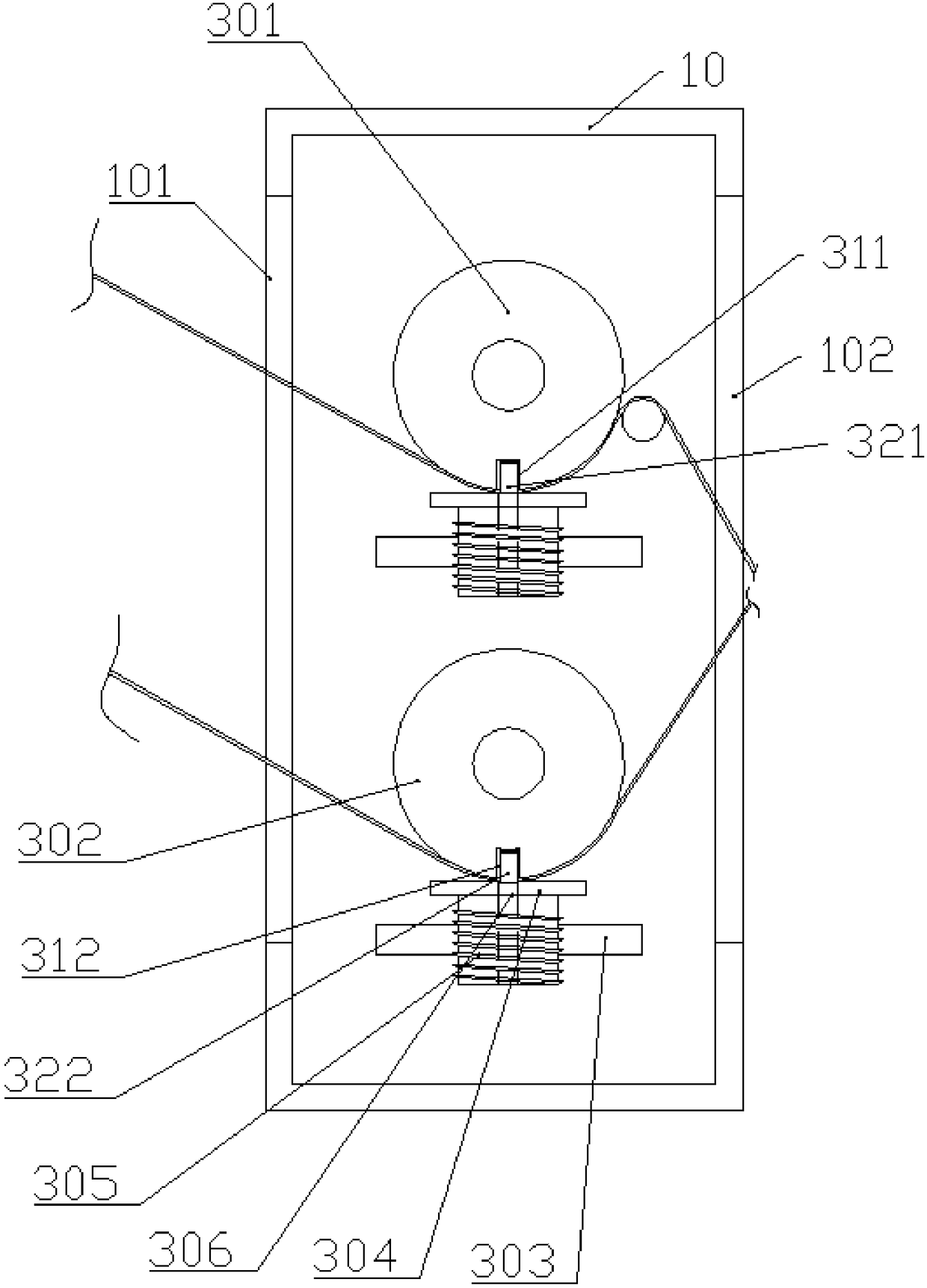

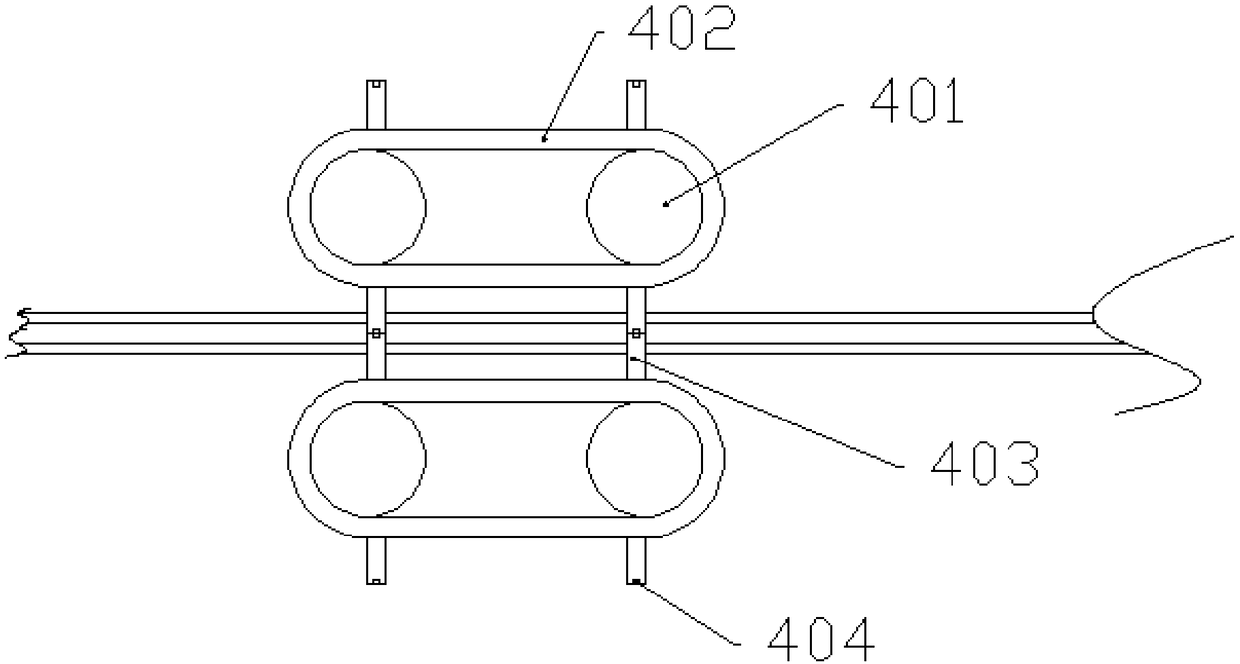

[0023] The reference signs in the accompanying drawings of the specification include: casing 10, inlet 101, outlet 102, first printing roller 301, first installation hole 311, first punching knife 321, second printing roller 302, second installation hole 312 , the second punching knife 322, the fixed plate 303, the support plate 304, the adjustment rod 305, the through hole 306, the conveyor pulley 401, the conveyor belt 402, the push rod 403, the connecting block 404, the housing 50, the first pressing plate 501, The second pressing plate 502 , the glue outlet plate 503 , the glue outlet 504 , and the threaded rod 505 .

[0024] The embodiment is basically as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 And attached Figure 5 Shown: Printing accuracy testing system, including conveying device, printing device, testing device, pressing device and winding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com