A microwave treatment device for potassium-bearing shale intermediates

A technology for microwave treatment and intermediates, which is applied in the field of microwave treatment devices for potassium-containing shale intermediates, can solve the problems of incomplete gas absorption, reduced harmful gas content, and high harmful gas temperature, so as to avoid excessively high outlet temperature and reduce equipment costs. Damage rate, excellent anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further limited below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection is not limited to the descriptions made.

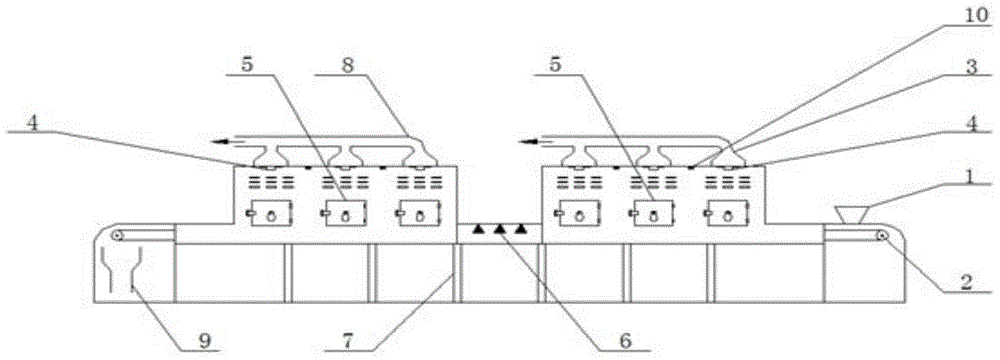

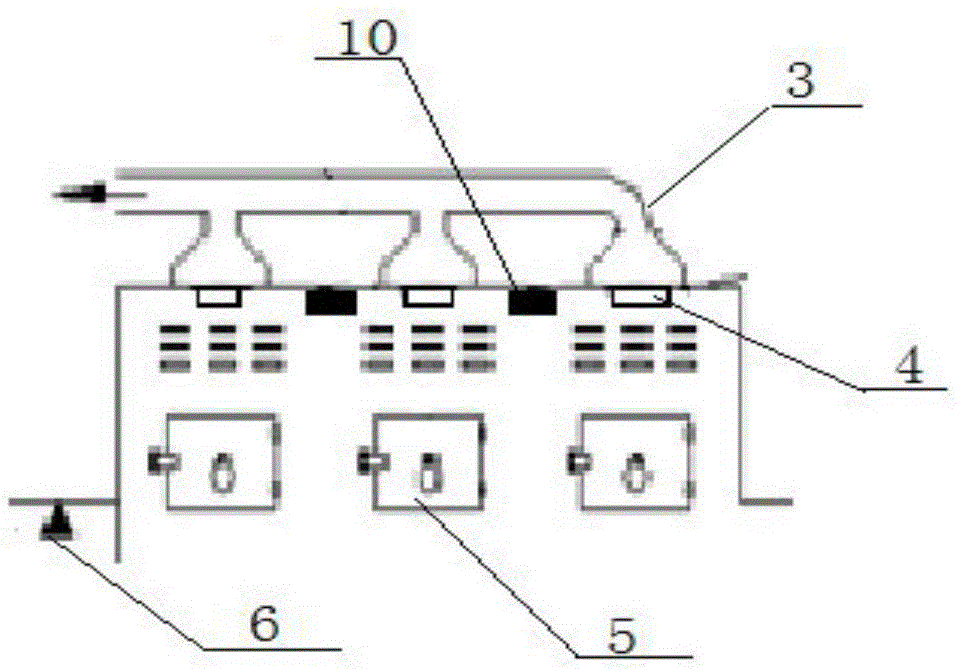

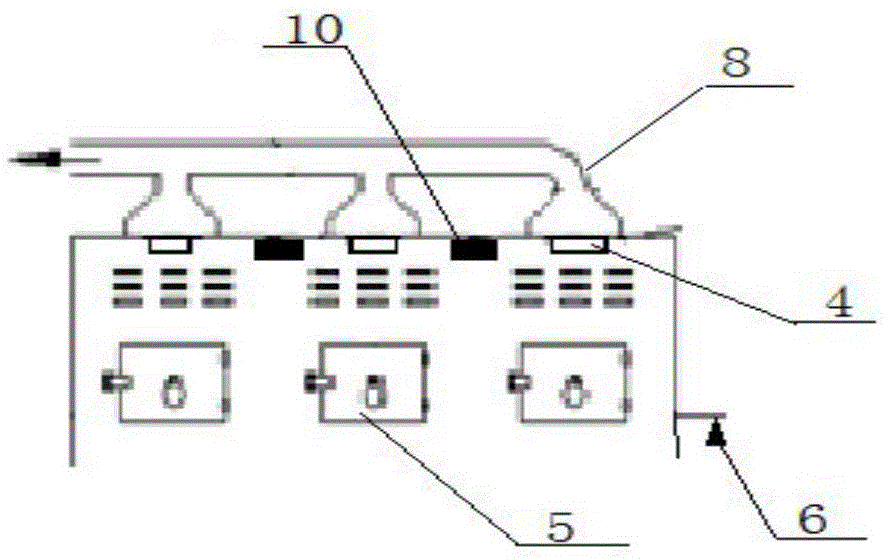

[0027] Such as figure 1 As shown, the microwave treatment device for potassium-bearing shale intermediates includes a first-stage microwave drying unit and a second-stage microwave processing unit. A conveyor belt 2 is arranged between the drying unit and the second-stage microwave processing unit, and the length of the conveyor belt 2 exceeds both ends of the first-stage microwave drying unit and the second-stage microwave processing unit, and a hopper is arranged on the conveyor belt 2 beyond the part of the first-stage microwave drying unit 1. A collecting hopper 9 is set at the end of the conveyor belt 2 that exceeds the second-stage microwave processing unit, and a shower head 6 is arranged on the conveyor belt 2 and between the first-stage microw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com