Part cooling device

A technology for cooling devices and parts, applied in the field of parts cooling devices, can solve the problems of partial cooling where parts cannot be in contact with the conveyor belt, less air flow in the cooling chamber, and poor cooling effect, etc., and achieve simple structure and faster speed. The effect of air flow and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

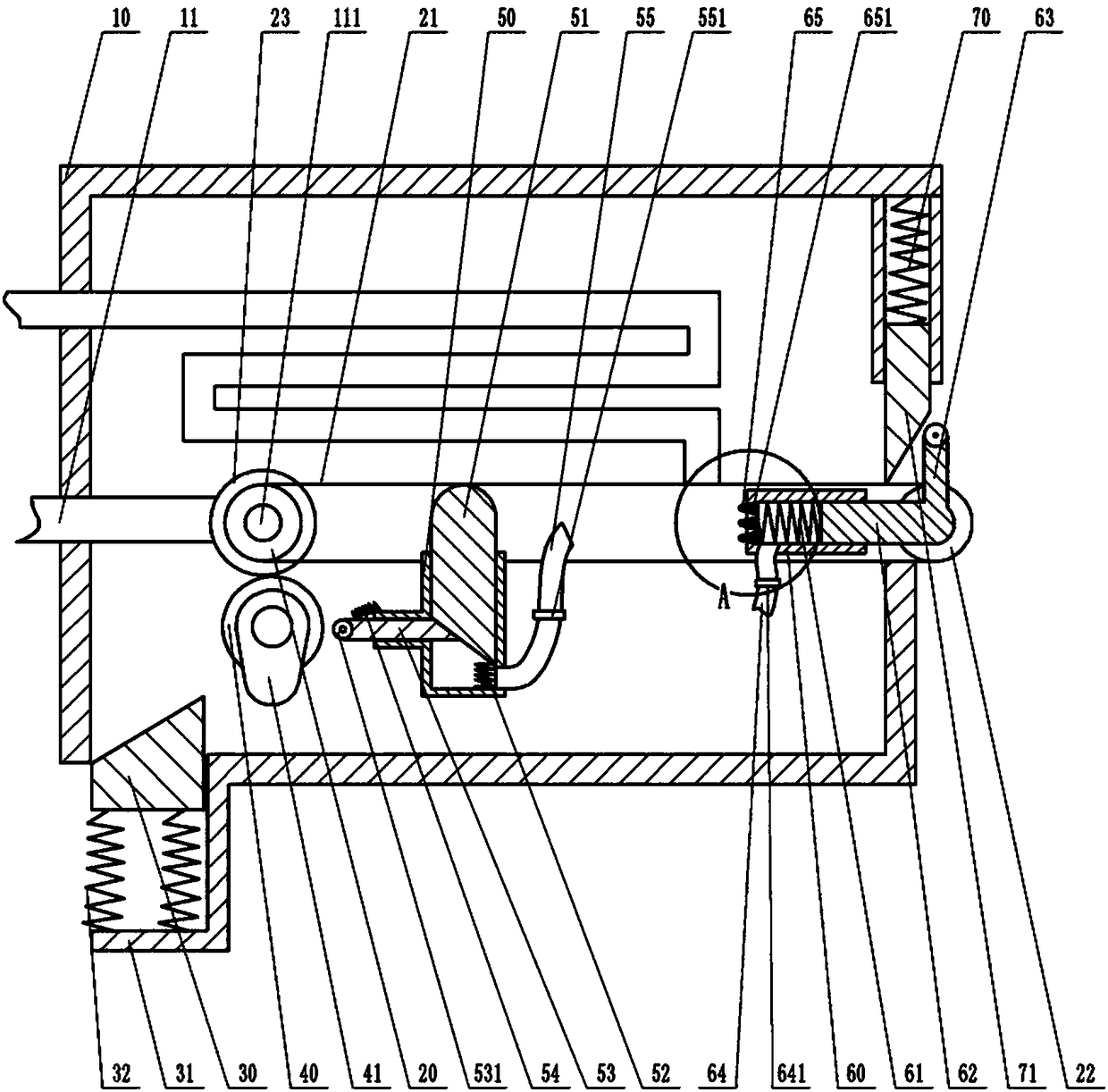

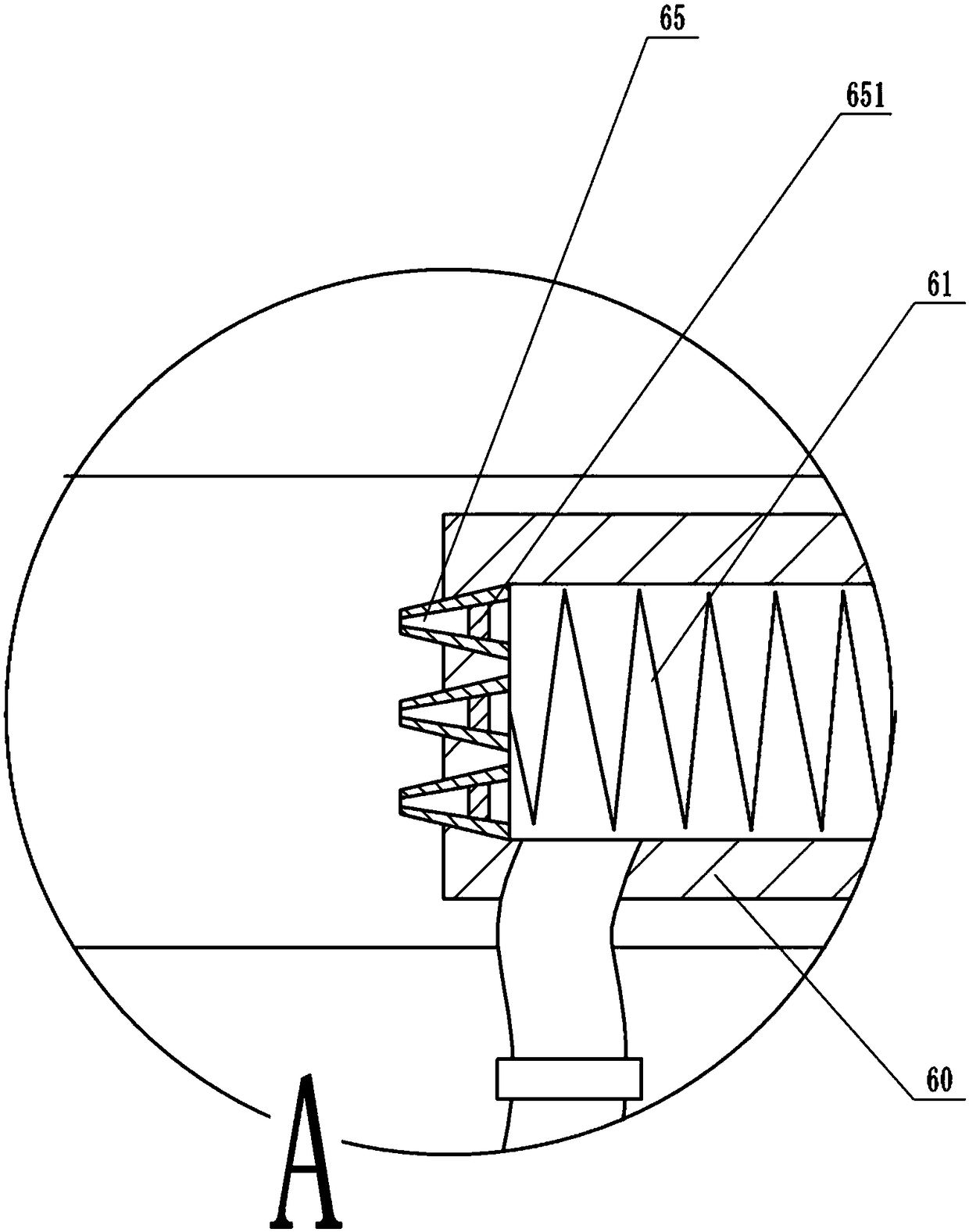

[0021] Instructions attached Figures 1 to 2 The reference signs in include: cooling chamber 10, cooling water pipe 11, transmission shaft 111, driving wheel 20, conveyor belt 21, driven wheel 22, first gear 23, wedge 30, support plate 31, fourth spring 32, the first Two gears 40, cam 41, piston barrel 50, plunger 51, first spring 52, push rod 53, roller 531, extension spring 54, exhaust pipe 55, one-way exhaust valve 551, spray tube 60, second spring 61, pressure post 62, push post 63, water inlet pipe 64, one-way water inlet valve 641, conical spray pipe 65, one-way drain valve 651, third spring 70, gate 71.

[0022] like figure 1As shown, the component cooling device includes a cooling chamber 10 , a conveying unit, a discharge unit, and a tightening unit and a spraying unit both located in the cooling chamber 10 . The transmission unit includes a driving wheel 20, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com