Phosphating wood and preparation method thereof

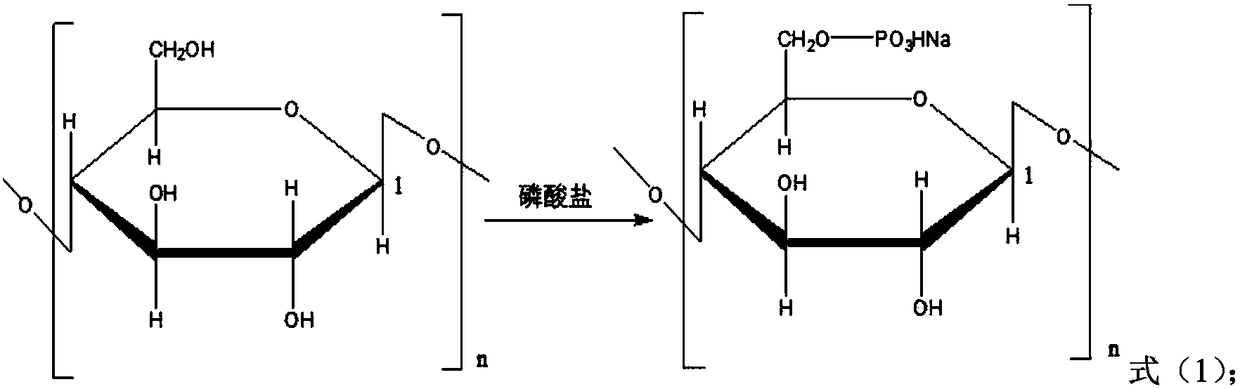

A technology of wood and phosphate ester, which is applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of improving the dimensional stability and flame retardancy of wood, and achieve excellent biodestruction resistance, good flame retardancy, Effect of improving dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of preparation method of phosphating wood of the present invention, comprises the following steps:

[0043](1) Process the wood into three kinds of specification test materials: 20(R)*20(R)*300(L)mm (mechanical performance test piece), 20mm*20mm*20mm (volume wet expansion test piece) and 100mm*100mm*10mm (flame retardant mechanical performance test piece), and numbered in sequence;

[0044] (2) Immerse poplar sapwood in NaOH solution with a mass fraction of 10%, alkalinize and impregnate at room temperature for 12 hours, then take out the plank and rinse it with deionized water for 2-3 times, and then dry it to a moisture content of about 8% ;

[0045] (3) Get 10g urea and 15g disodium hydrogen phosphate to be dissolved in 120g water, prepare reaction solution;

[0046] (4) Seal the wood after step (2) in the impregnation reaction tank, vacuumize the impregnation reaction tank, vacuumize to below 0.1MPa, then inject the reaction solution obtained after step (3)...

Embodiment 2

[0050] A kind of preparation method of phosphating wood of the present invention, comprises the following steps:

[0051] (1) Process the wood into three kinds of specification test materials: 20(R)*20(R)*300(L)mm (mechanical performance test piece), 20mm*20mm*20mm (volume wet expansion test piece) and 100mm*100mm*10mm (flame retardant mechanical performance test piece), and numbered in sequence;

[0052] (2) Immerse poplar sapwood in NaOH solution with a mass fraction of 10%, alkalinize and impregnate at room temperature for 12 hours, then take out the plank and rinse it with deionized water for 2-3 times, and then dry it to a moisture content of about 8% ;

[0053] (3) get 20g urea and 15g disodium hydrogen phosphate to be dissolved in 120g water, prepare reaction solution;

[0054] (4) Seal the wood after step (2) in the impregnation reaction tank, vacuumize the impregnation reaction tank, vacuumize to below 0.1MPa, then inject the reaction solution obtained after step (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com