A high-energy short-pulse laser processing method for removing stealth coatings on metal surfaces

A short-pulse laser and processing method technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of easily damaged metal surface, unsuitable for coating removal, uncontrollable process, etc., to achieve less damage to the substrate , the effect of small impact and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

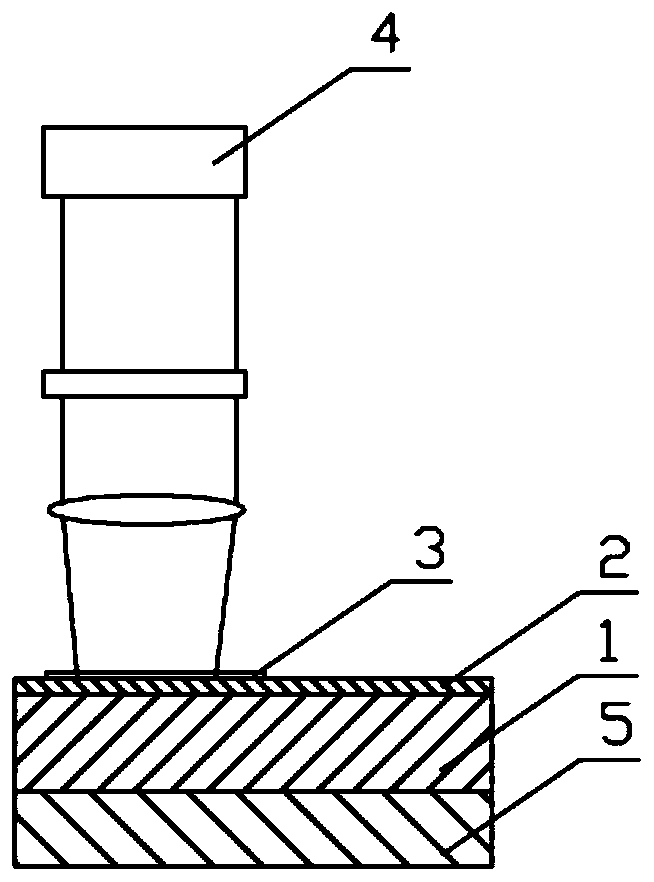

[0026] A layer of water film 3 is covered on the surface of the stealth coating 2, and the water film 3 is irradiated with a high-energy short-pulse laser, and the water film 3 is scanned by laser by controlling the laser parameters, overlapping rate and scanning path, and then the water film 3 is removed, and then The stealth coating 2 is quickly stripped and removed from the surface of the metal member 1 . The specific process steps are as follows:

[0027] (1) Paste rubber on the uncoated back of the metal component 1, and fix it on the fixture of the robot, and align the side with the stealth coating 2 with the laser light outlet 4; during the processing, the laser beam does not move relative to the ground , the metal component 1 is clamped by the robot and moves relative to the ground, so as to realize the scanning of the laser beam on the surface of the metal component 1, and the moving speed of the robot should match the laser pulse frequency.

[0028] (2) A layer of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com