Main valve body for excavator grab bucket control

A main valve body, excavator technology, applied in valve details, valve device, valve shell structure and other directions, can solve the problems of poor sealing, easy leakage, poor flow channel forming, etc., to achieve good fluidity, eliminate The effect of small pores and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

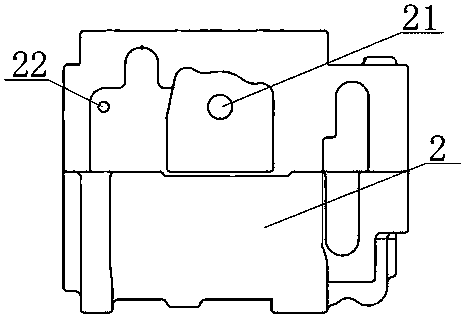

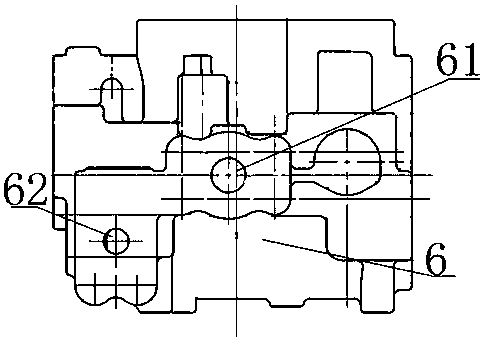

[0057] Refer to attached Figure 1-16 , the main valve body for excavator grab control, the main valve body is designed in a square shape, the upper surface 1 of the main valve body is designed as a plane, the upper surface 1 is designed with a step on the right side, and the upper surface 1 is designed with six runner ports 11 , three are evenly arranged in a row; there is a bulge on the front 2 of the main valve body and a flow channel opening 21 is designed on the bulge, a step is also designed on the lower side of the front 2, and a small flow channel opening 22 is designed on the upper left corner of the front 2; There are seven runner ports designed on the left side 3 of the main valve body, three runner ports 31 in a row above, two runner ports 32 in a row in the middle, and two runner ports 33 in a row below; the right side of the main valve body 4. Five runner ports are designed, three runner ports 41 in a row above, and two runner ports 42 in a row in the middle; two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com