Smoke and dust removal device for rural garbage treatment

A technology of garbage disposal and dust removal device, which is applied in the direction of combination device, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inability to mix cooling liquid, low cooling efficiency, greenhouse effect, etc., and achieves easy cooling, desulfurization and dust removal, The effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

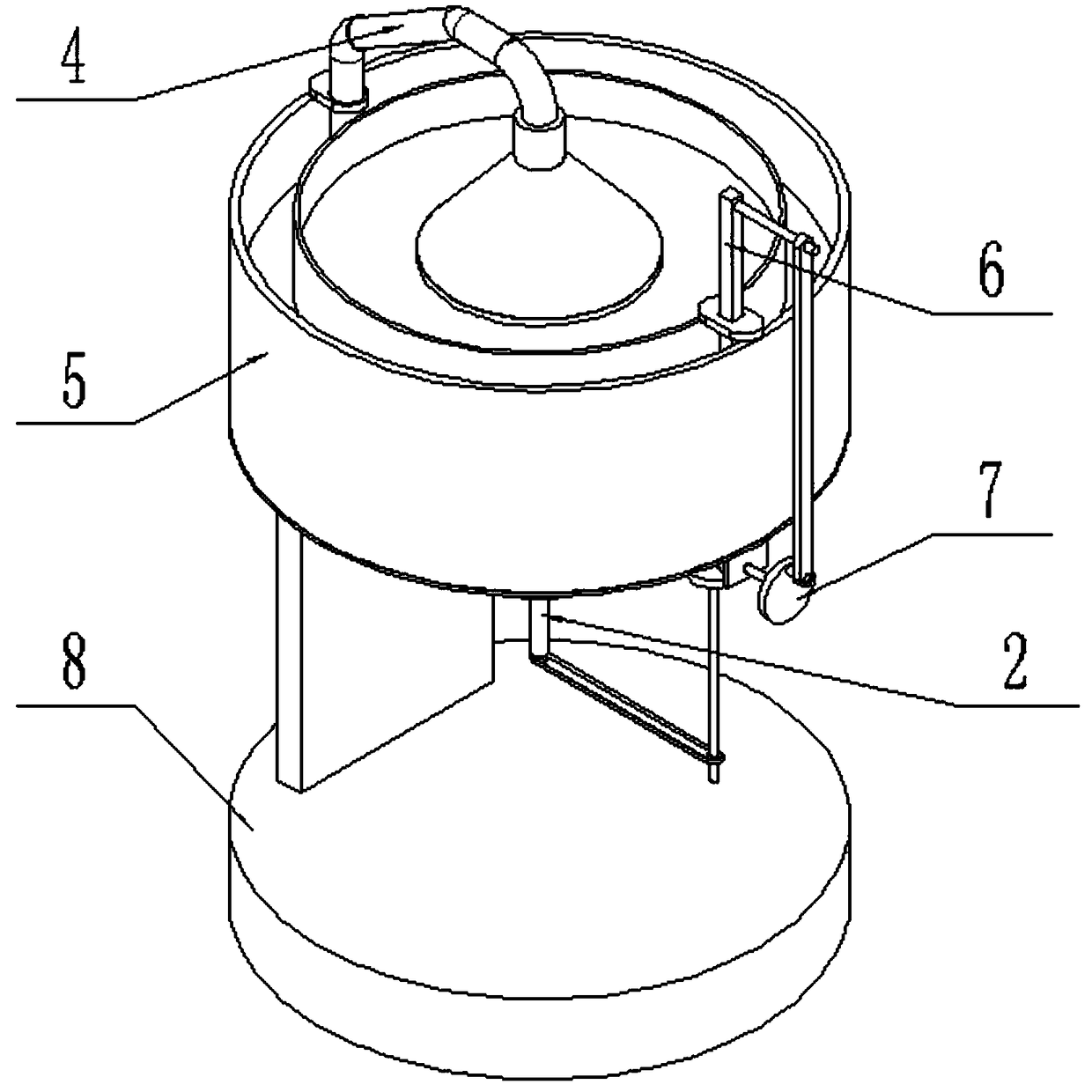

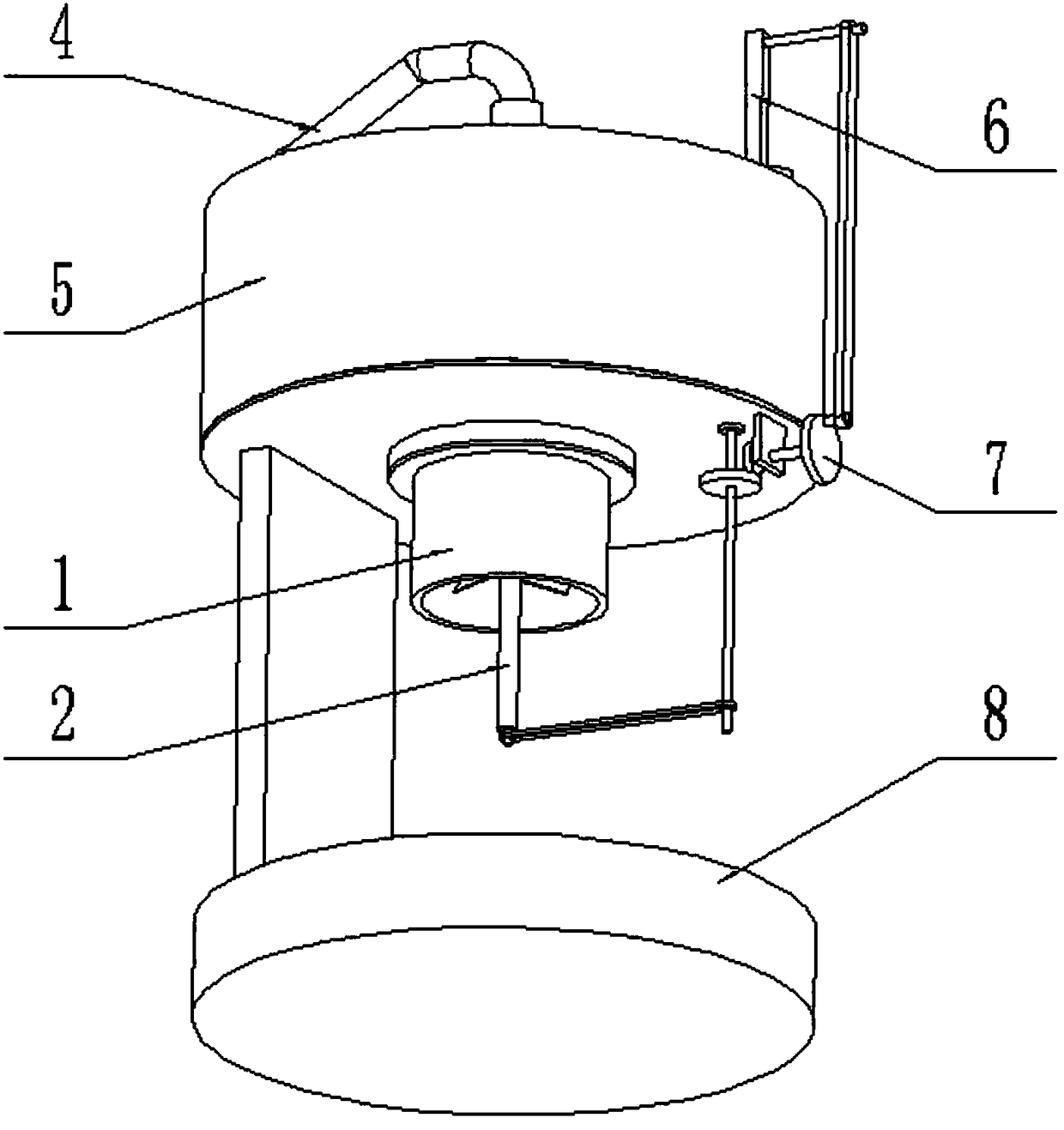

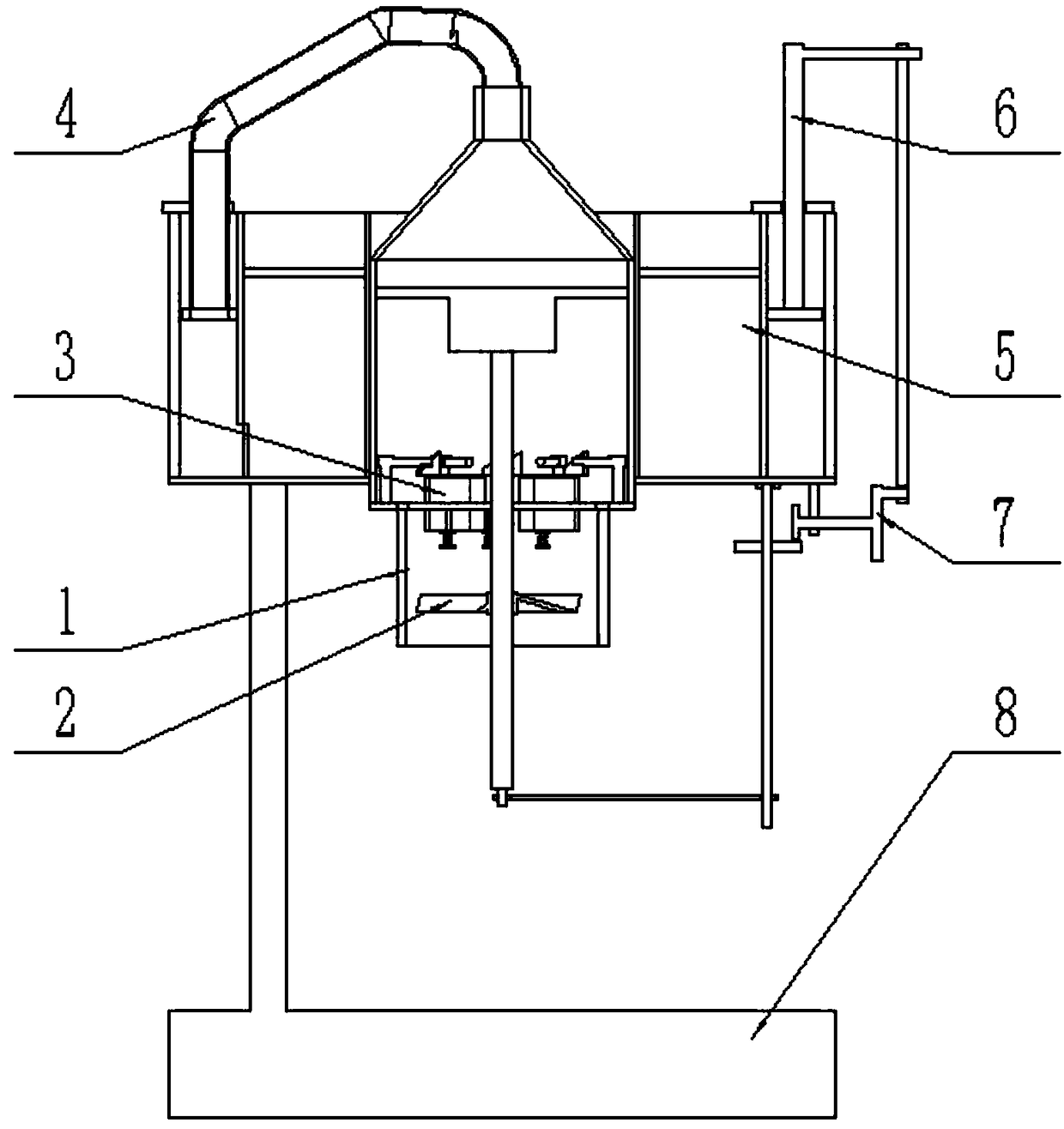

[0032] like Figure 1-13 As shown, the smoke and dust removal device for rural garbage treatment includes a dust collection box assembly 1, a dust collection impeller assembly 2, a rotary filter device 3, a dust delivery pipe assembly 4, a dust removal water tank assembly 5, a lift transformer plate assembly 6, and a transmission wheel Assembly 7 and supporting base 8, the dust collection box assembly 1 includes a dust suction pipe 1-1, a dust blocking pipe 1-2, a fixed seat plate 1-3, six blocking dust rods 1-4 and a pipe connection ring 1 -5; the upper end of the dust suction pipe 1-1 is fixedly connected to the lower end of the pipe connection ring 1-5, and the upper end of the pipe connection ring 1-5 is fixedly connected to the dust blocking pipe 1-2; the pipe connection ring 1-5 The top surface of the top surface is evenly arranged with six blocking dust rods 1-4; the fixed seat plate 1-3 is fixedly connected to the inner upper end of the dust blocking pipe 1-2;

[0033] ...

specific Embodiment approach 2

[0035] like Figure 1-13 As shown, the rotary filter device 3 includes a rotary dust-blocking plate 3-1, a stainless steel dust-removing basket 3-2, a sloping plate 3-3 and a spring seat assembly 3-4; the rotary dust-blocking plate 3-1 is fixedly connected On the rotating shaft 2-2, the outer wall of the rotating dust blocking plate 3-1 is tangent to the upper end of the inner wall of the dust suction pipe 1-1; the rotating dust blocking plate 3-1 is provided with six slotted openings, six The inboards of each slot-shaped opening are respectively slidingly fitted to connect a stainless steel dust removal net basket 3-2, and the tops of six stainless steel dust removal net baskets 3-2 are respectively fixedly connected with a slant plate 3-3, and the tops of the six stainless steel dust removal net baskets 3-2 are fixedly connected. Each bottom end is fixedly connected to a spring seat assembly 3-4, and the upper end of the spring seat assembly 3-4 is fixedly connected to the b...

specific Embodiment approach 3

[0038] like Figure 1-13 As shown, the dust delivery pipe assembly 4 includes a dust delivery bucket 4-1, a telescopic hose 4-2 and a lift slide tube 4-3; the lower end of the dust delivery bucket 4-1 is fixedly connected and communicated with the dust blocking pipe 1 -2; the upper end of the dust hopper 4-1 is fixedly connected to one end of the flexible hose 4-2, and the other end of the flexible hose 4-2 is fixedly connected to the lifting slide pipe 4-3; the lifting slide The lower end of the pipe 4-3 is fixedly connected to the lifting transformer plate assembly 6. When the dust conveying pipe assembly 4 is in use, the flue gas enters the interior of the dust conveying hopper 4-1 through the dust blocking pipe 1-2, and enters the telescopic hose 4-2 and the lifting slide through the dust conveying hopper 4-1. The inner side of the pipe 4-3 finally enters the inside of the dust removal water tank assembly 5 through the lifting slide pipe 4-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com