Support cylinder assembly with two sealing grooves for three-way shell

A double-seal and support technology, which is applied in the direction of electrical components, busbar/line layout, substation/switch layout details, etc., can solve the problems of large welding deformation and welding stress, and achieve the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

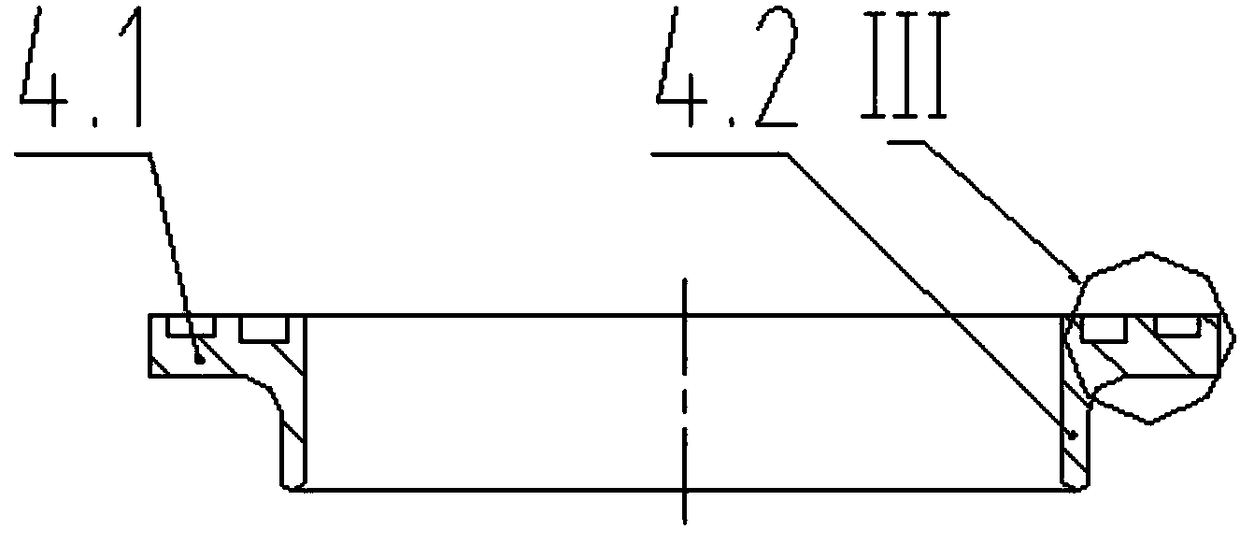

[0013] The double-sealed groove tee shell support assembly shown in the attached figure includes support flange 4.1 and support 4.2; one end of support 4.2 is flanged to form support flange 4.1, namely support 4.2 and support flange 4.1 for an integrated structure.

[0014] The outer end surface of the flange 4.1 of the support tube is provided with an outer sealing groove II 4.4 and an inner sealing groove II 4.3 which are coaxially fitted and have the same groove width; the depth of the outer sealing groove II 4.4 is smaller than that of the inner sealing groove II 4.3 depth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com