A Measuring Method for Tensile Stress Corrosion of Deformed Aluminum Alloy

A technology of deforming aluminum alloy and tensile stress, which is applied in the direction of measuring device, weather resistance/light resistance/corrosion resistance, using stable tension/pressure test material strength, etc., which can solve the problem of corrosion sensitivity, uncertain loading method, Quantitative measurement methods and other issues, to achieve a reasonable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

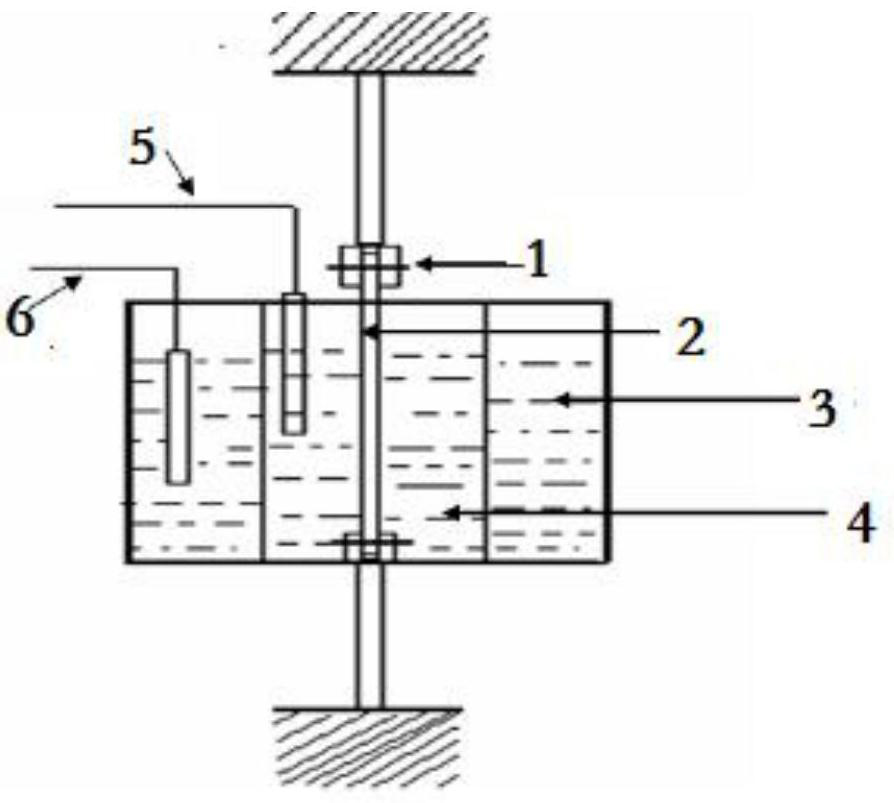

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0036] Based on the above purpose, an embodiment of the present invention proposes a method for measuring tensile stress corrosion of deformed aluminum alloys, which can quantitatively measure the stress corrosion sensitivity of aluminum alloys.

[0037] A method for measuring tensile stress corrosion of deformed aluminum alloy provided by the invention comprises the following steps:

[0038] Remove the aluminum-clad layer on the surface of the sample;

[0039] The stress corrosion susceptibility is measured by the relative change of the same mechanical parameters of the same specimen exposed to the comparative test environment and to the inert environment;

[0040] The stress corrosion susceptibility is expressed as:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com