A vacuum flow test device for air pipe head

A technology of air tube head and flow test, which is applied in the direction of measuring device, volume/mass flow generated by mechanical effect, testing of mechanical parts, etc. Results with high precision and advanced equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

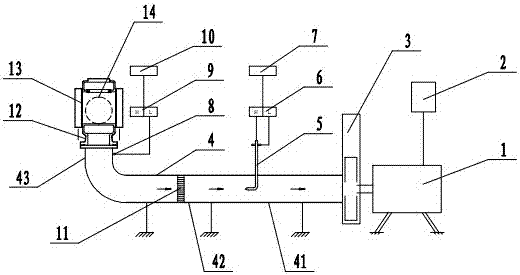

[0014] Further description will be given below for the embodiments of the present invention:

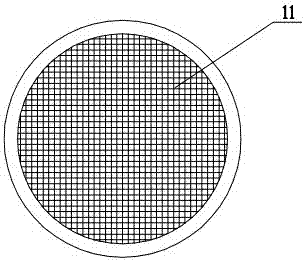

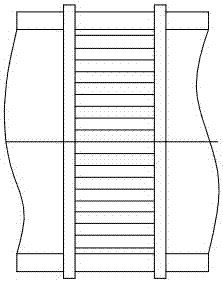

[0015] As shown in the figure, a vacuum flow test device for an air pipe head includes a motor 1, a frequency converter 2, a fan 3, a measuring pipe 4, a pitot tube 5, a first pressure transmitter 6, a first display 7, an air pressure Sensor 8, the second pressure transmitter 9 and the second display 10, the fan 3 is a centrifugal fan, the measuring pipeline 4 includes a straight pipe section 41, a rectifier section 42 and a vacuum pressure measuring section 43 connected in sequence, the motor 1 is connected to the fan 3, the frequency converter 2 is connected to the motor 1, the fan 3 is connected to the straight pipe section 41, the pitot tube 5 is installed on the straight pipe section 41, and the first pressure transmitter 6 Connected with pitot tube 5, the first display 7 is connected with the first pressure transmitter 6, the air pressure sensor 8 is arranged on the vacuum pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com