Height-adjustable clamping mechanism for aluminum alloy short pipe cutting

A clamping mechanism, aluminum alloy technology, applied in the direction of shearing devices, metal processing equipment, shearing machine accessories, etc., can solve the problems of easy deformation of the cutting part and high difficulty of clamping at both ends, and achieve the effect of improving the cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

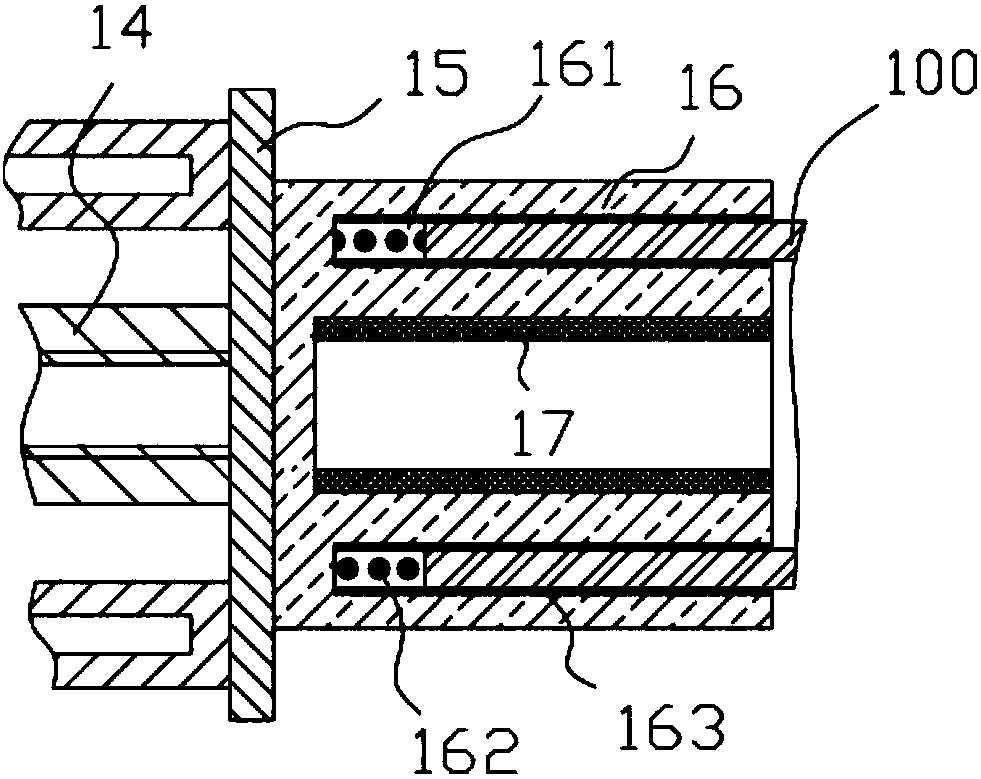

[0019] Example: see Figure 1 to Figure 2 As shown, a height-adjustable clamping mechanism for aluminum alloy short pipe cutting includes a frame 10 and a lifting bottom plate 20, and vertical lifting support plates 21 are fixed on the left and right sides of the top surface of the top plate of the frame 10. An upper horizontal support plate 22 is fixed on the inner side wall of the top surface of the vertical lifting support plate 21, and two vertical adjustment screw rods 23 are located on both sides of the top plate of the frame 10, and the tops of the vertical adjustment screw rods 23 are hinged on the corresponding upper horizontal support plates. On the plate 22, the bottom of the vertical adjustment screw rod 23 is hinged on the top plate of the corresponding frame 10, and the bottom end of the vertical adjustment screw rod 23 stretches out from the bottom surface of the top plate of the frame 10 and is fixed with a lifting bevel gear 24, and the frame 10 The middle par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com