Preparation method for gamma-iron trioxide/rGO composite material having flower-like microsphere structure

A technology of ferric oxide and composite materials, applied in the direction of catalyst activation/preparation, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problem of reduced active sites, high specific surface energy, and easy agglomeration and other problems, to achieve the effects of easy access, increased specific surface area, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh 0.248g of ferric nitrate nonahydrate and dissolve it in 10mL of ethylene glycol, and stir magnetically for 30min;

[0027] (2) Sodium hydroxide is added to water to obtain a 5mol / L aqueous sodium hydroxide solution, and the 5mol / L aqueous sodium hydroxide solution is slowly added dropwise to the solution obtained in step 1, and the stirring is continued for 30min;

[0028] (3) After stirring, transfer the reaction solution into a 25mL hydrothermal kettle, and react at 150-180°C for 12-18 hours;

[0029] (4) After the reaction, naturally cool to room temperature, centrifuge and wash, and air-dry at 200° C. for 12 hours to obtain product 1.

[0030] (5) The solvent volume ratio required for the reaction is: ethylene glycol: water = 2:1.

Embodiment 2

[0032] (1) Weigh 5 mg of graphene oxide in 10 mL of ethylene glycol, and ultrasonically disperse at 600 W for 2 to 3 hours until a brown-yellow transparent suspension is formed;

[0033] (2) Take by weighing 0.248g ferric nitrate nonahydrate in the suspension liquid of step (1) gained, magnetic stirring 30min;

[0034] (3) Sodium hydroxide is added in water, obtains the aqueous sodium hydroxide solution of 5mol / L, the aqueous sodium hydroxide solution (the volume of water is 5mL) of 5mol / L is slowly added dropwise in the solution of step (2) gained, After dropping, continue to stir for 30min to obtain the reaction solution;

[0035] (4) Transfer the reaction solution into a 25mL hydrothermal kettle, and react at 150°C for 12h;

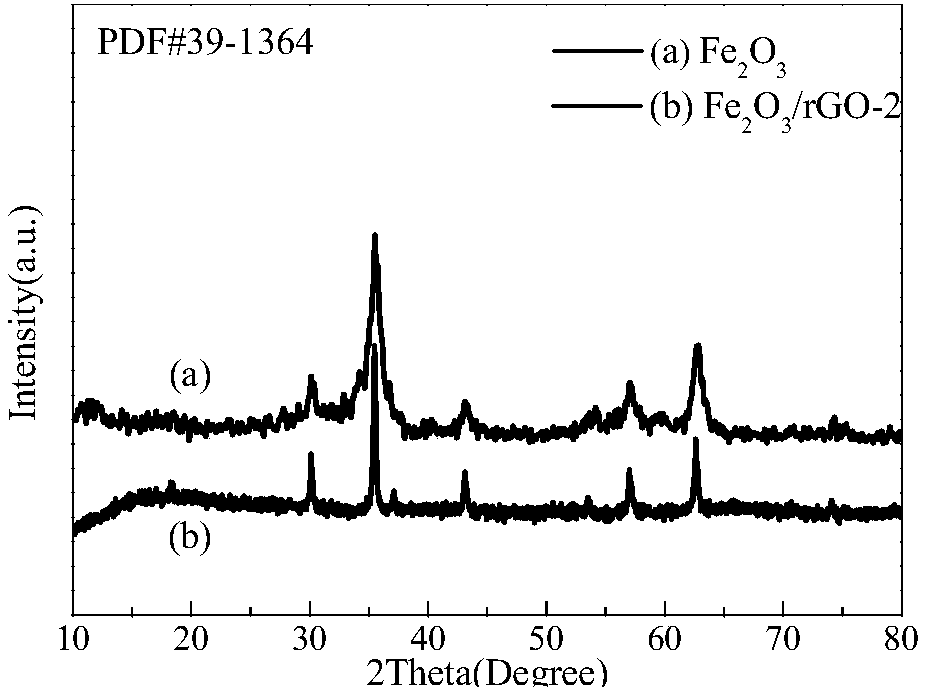

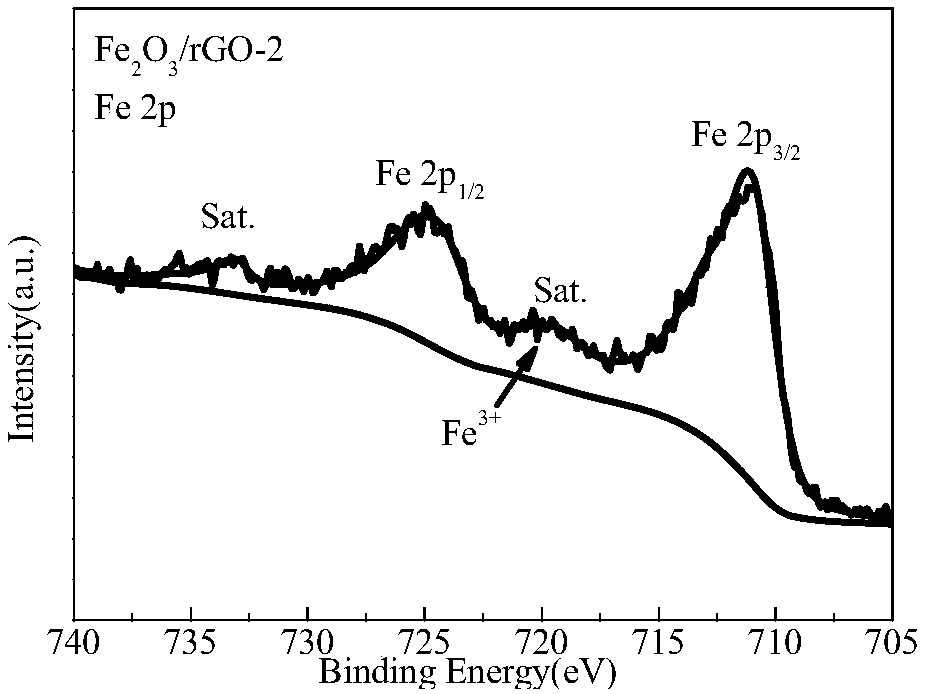

[0036] (5) After the reaction, naturally cool to room temperature, centrifuge and wash, and blow dry at 200°C for 12 hours to obtain the flower-shaped microsphere structure γ-Fe2O3 / rGO composite material, namely product 2 (marked as Fe 2 o 3 / rGO-0....

Embodiment 3

[0038] (1) Weigh 20 mg of graphene oxide in 10 mL of ethylene glycol, and ultrasonically disperse at 600 W for 2 to 3 hours until a brown-yellow transparent suspension is formed;

[0039] (2) Take by weighing 0.248g ferric nitrate nonahydrate in the suspension liquid of step (1) gained, magnetic stirring 30min;

[0040] (3) Sodium hydroxide is added in water, obtains the aqueous sodium hydroxide solution of 5mol / L, the aqueous sodium hydroxide solution (the volume of water is 5mL) of 5mol / L is slowly added dropwise in the solution of step (2) gained, Continue stirring for 30min after dropping to obtain the reaction solution;

[0041] (4) After stirring, transfer the reaction liquid into a 25mL hydrothermal kettle, and react at 150°C for 12h;

[0042] (5) After the reaction, naturally cool to room temperature, centrifuge and wash, and blow dry at 200°C for 12 hours to obtain the γ-Fe2O3 / rGO composite material with flower-like microsphere structure, namely product 3 (marked as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com