Konjac glucomannan gel preparation device and method

A technology of konjac glucomannan and preparation device, applied in gel preparation, chemical instruments and methods, colloid chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

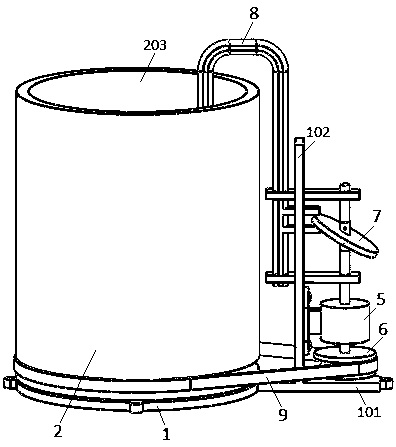

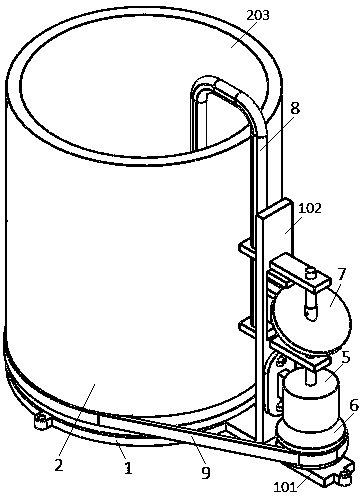

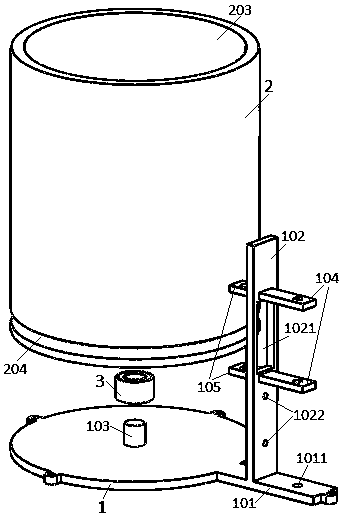

[0043] The device for preparing konjac glucomannan gel of the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0044] A konjac glucomannan gel preparation device is characterized in that it comprises a base plate 1 , a tank body 2 , a bearing 3 , a tapered roller 4 , a motor 5 , a pulley 6 , a driving wheel 7 , a stirrer 8 , and a belt 9 .

[0045] like image 3 , Figure 4 , Figure 5 , Image 6 As shown, the base plate 1 is a flat circular plate placed horizontally, and a central column 103 protruding upward is provided at the center of the top surface, which is installed in the inner ring of the bearing 3; the tank body 2 is a cylindrical shape with an open top surface. Shell, a cylindrical bearing cavity 201 is opened at the center of the bottom surface of the tank body 2, and the outer ring of the bearing 3 is embedded in the bearing cavity 201; the bottom surface of the tank body 2 surrounds the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com