Method for detecting flavoring uniformity of cut tobacco based on main component analysis technology

A technique of principal component analysis and uniformity, which is applied in the field of tobacco manufacturing, can solve the problems that cannot be popularized and applied, the test results are not intuitive and accurate enough, and the quality requirements of testing instruments and testing personnel are high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

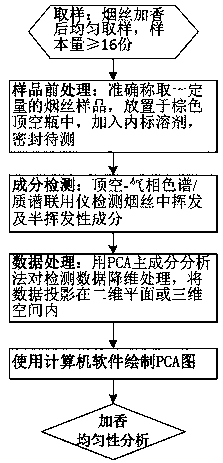

Method used

Image

Examples

Embodiment 1

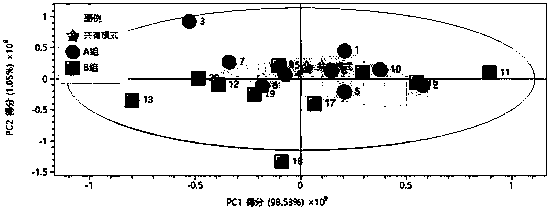

[0029] According to the method for detecting the flavoring uniformity of shredded tobacco based on the principal component analysis method established in the present invention, the drum flavoring process of a certain brand in the silk making process of a certain production plant is tested and analyzed under different production process conditions, and the uniformity of flavoring is tested. The results guide the optimization of the process parameters of the silk production line. The specific test steps are:

[0030] a. Sample preparation:

[0031] Sample 1: The process parameters of the aromatization process are set as follows: flow rate 8000kg / h, atomization medium air pressure 0.3Mpa, drum speed 9r / min, and aromatization ratio 0.33%. Sampling method: After the equipment is running stably, 20 cut tobacco samples are continuously taken from the drum flavoring outlet every 1 minute, each sample is 10g, and placed in a plastic sealed bag.

[0032] Sample 2: The process paramete...

Embodiment 2

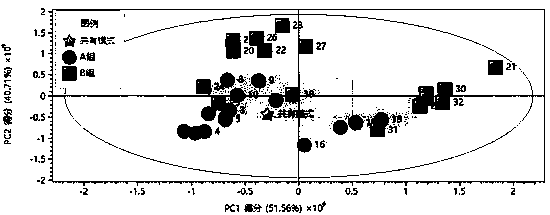

[0046] The method for detecting flavoring uniformity of shredded tobacco based on principal component analysis established according to the present invention is used for comparative analysis of flavoring uniformity of different flavoring methods (thread drum flavoring, laboratory artificial spray flavoring). The specific test steps are:

[0047] Sample preparation:

[0048] Sample 1: Silk thread made by a certain production plant, in the normal production process of a certain brand, set according to the normal process standard parameters, the process flow rate is 8000kg / h, the air pressure of the atomizing medium is 0.3Mpa, the drum speed is 9r / min, and the fragrance is set The ratio is 0.33%. After the equipment is running stably, 20 samples are continuously taken from the outlet of the aromatizing drum every 1 minute, 20g of each sample is taken, and placed in a plastic sealed bag.

[0049] Sample 2: For the same brand of shredded tobacco, all the processing procedures of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com