Centrifugal compressor diffusor structure with blades being integrated with case and hub

A centrifugal compressor and diffuser technology, used in machines/engines, mechanical equipment, gas turbine devices, etc., can solve the difficulties in the design, modeling and processing of diffuser blades, serious distortion of diffuser blades, and problems in diffuser blades. Design difficulties and other problems, to achieve the effect of easy blade design and processing, without reducing the performance of the compressor, and reducing the mixing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with embodiments. The following embodiments are for explaining the present invention, and the present invention is not limited to the following embodiments.

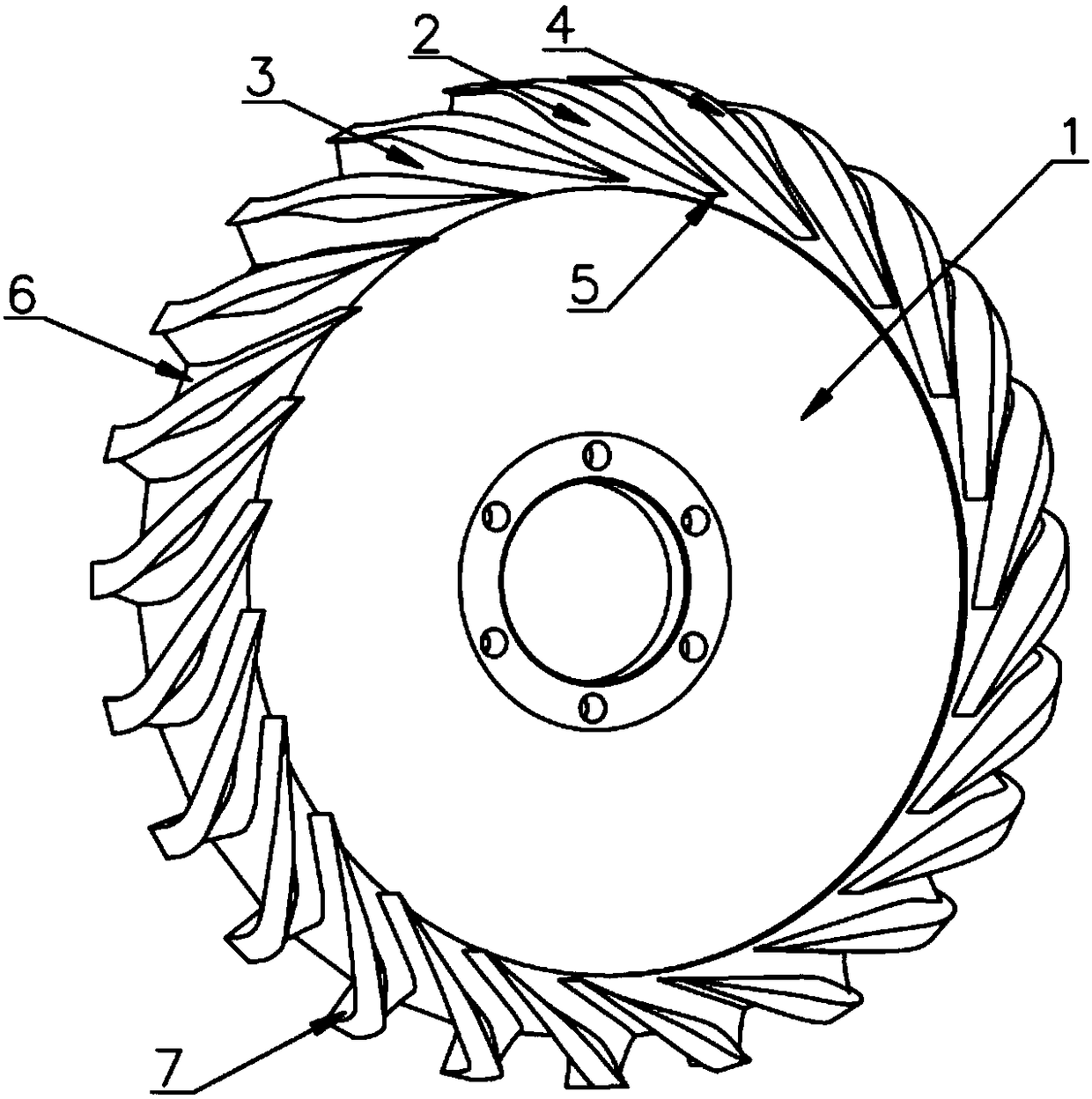

[0026] Such as Figure 1 to Figure 5 As shown, the diffuser structure of the centrifugal compressor with blades, casing and hub of the present invention includes a diffuser body 1. The diffuser body 1 is composed of a diffuser blade and a diffuser disc. The diffuser The number of blades is between 10 and 35. During processing, the diffuser blades can be processed by milling the diffuser airflow channel 9 on the diffuser disk. A plurality of diffuser blades are integrally formed and evenly distributed on the peripheral edge portion of the diffuser disc, the space between two adjacent diffuser blades is formed as a diffuser airflow channel 9, and each diffuser blade includes The radial blade segments on the end surface of the diffuser disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com