Optimizing method for parameters of hydraulic fracturing proppant for sandstone reservoir

A technology for hydraulic fracturing and optimization methods, which is applied in earth-moving drilling, fluid production, wellbore/well components, etc. It can solve the problems of rough surface damage of rock samples, inability to repeat multiple experiments, and inability to guide oil fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described below in conjunction with accompanying drawing and example.

[0078] A method for optimizing proppant parameters for hydraulic fracturing of sandstone reservoirs, the main steps are as follows:

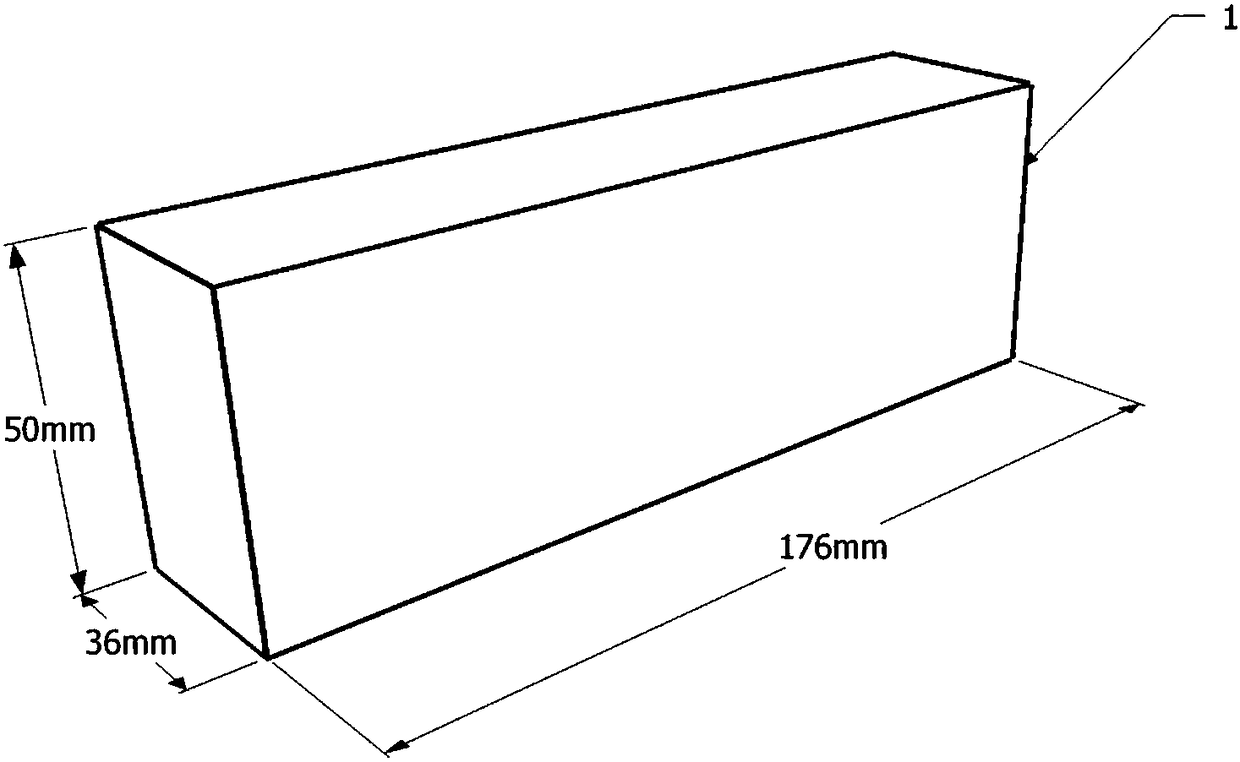

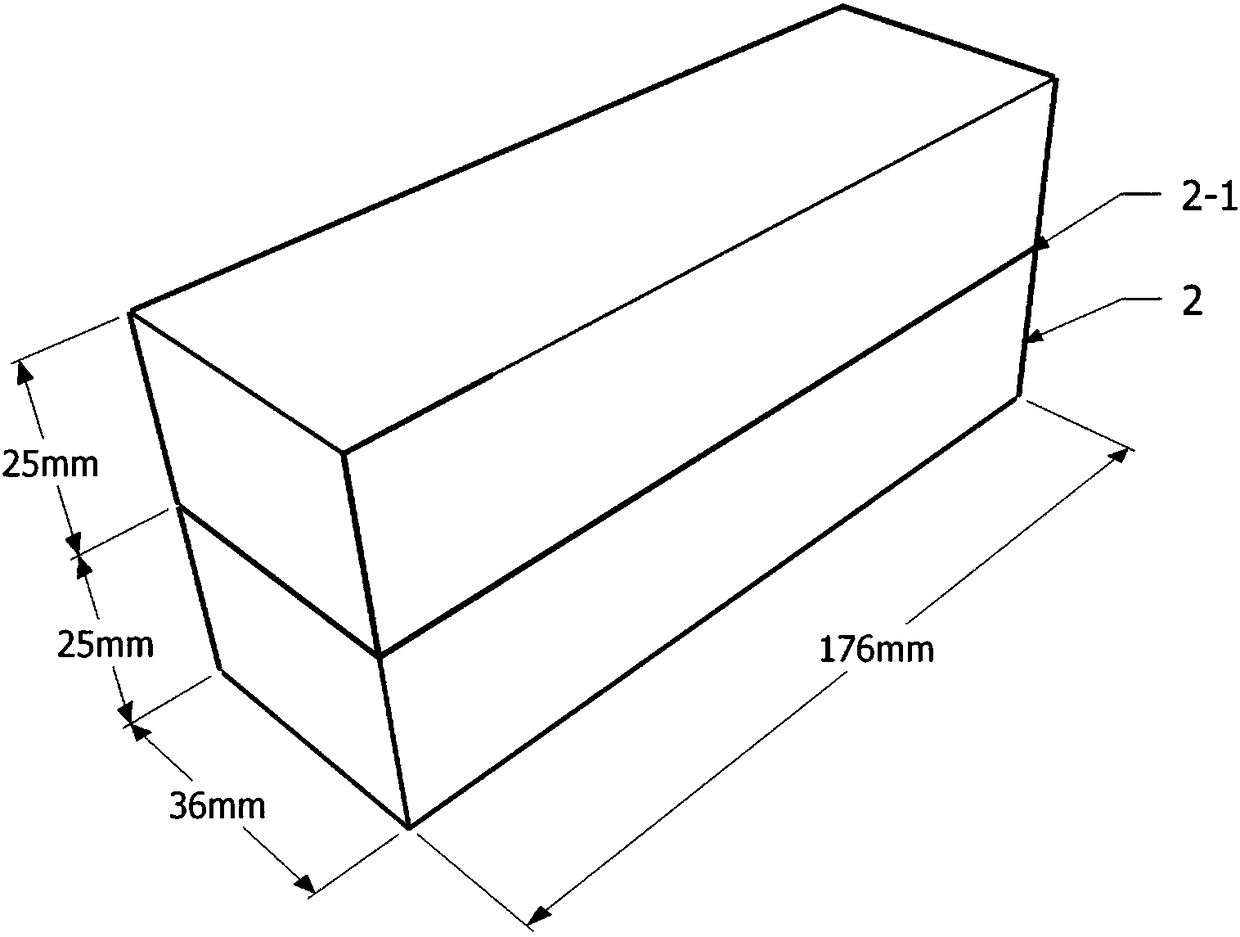

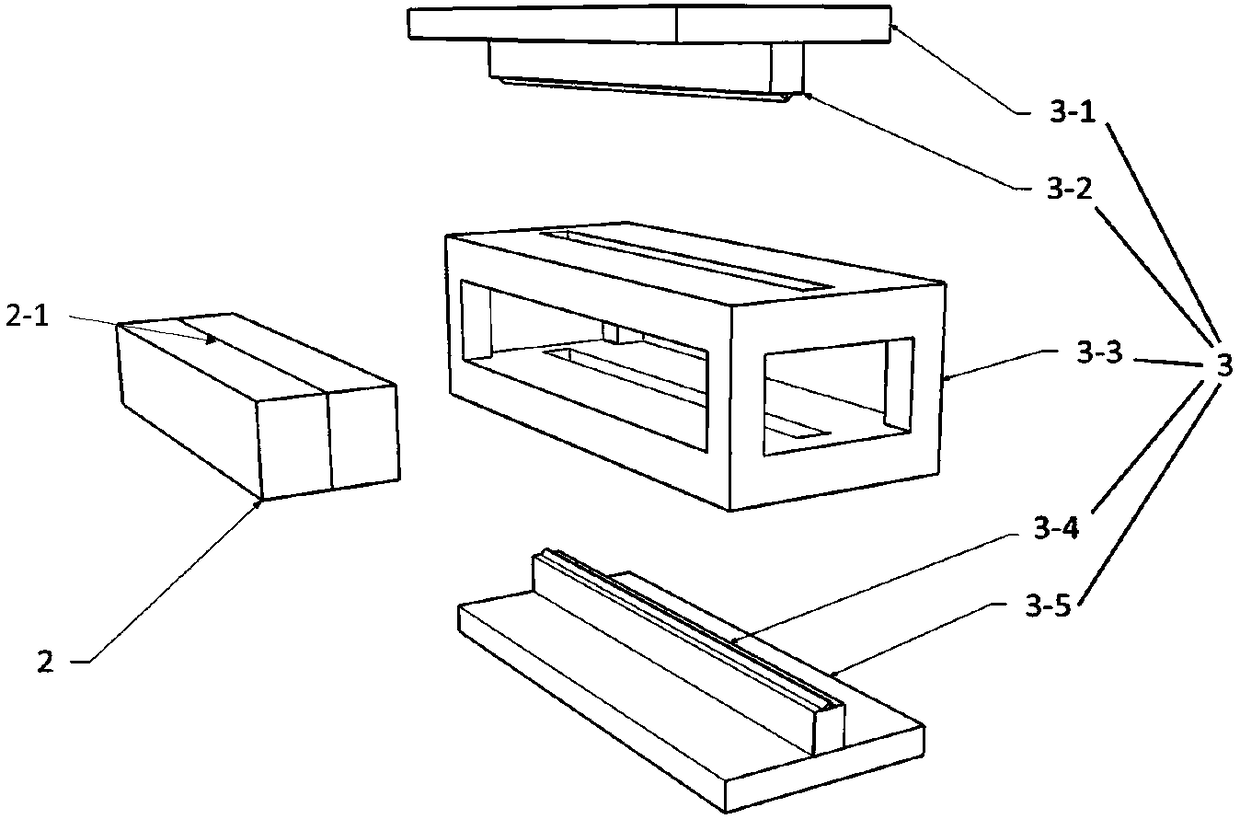

[0079] Use the simulation software Eclipse to calculate the optimal fracture conductivity of the sandstone reservoir; use the downhole core of the sandstone reservoir section to make the original square rock slab 1; prefabricate the scratch 2-1 in the middle of the original square rock slab 1; use the rock slab splitting device 3 Split the prefabricated scratched square rock slab 2, and use a three-dimensional laser scanner to obtain the surface roughness data of the split rock sample 4; calculate the crack surface roughness coefficient JRC, and select a pair of the most representative The split rock sample 4 of the hydraulic fracture surface morphology of the sandstone reservoir; the selected split rock sample 4 is further cut in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com