Novel anti-hydrogen-embrittlement TSC pile and production process thereof

A production process and hydrogen-proof technology, applied in sheet pile walls, reinforced molding, infrastructure engineering, etc., can solve problems such as troublesome processing and manufacturing, concrete exposure, hydrogen embrittlement, etc., to prevent concrete exposure, ensure tension effect, and manufacture convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

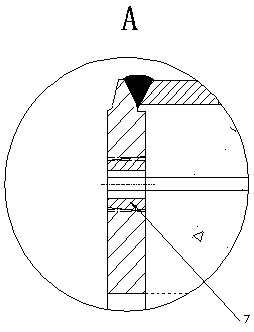

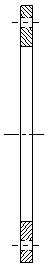

[0047] Such as Figure 1-Figure 22A new anti-hydrogen embrittlement TSC pile is shown, including

[0048] A pile body 3, the pile body 3 is a hollow cylinder structure, and a steel pipe 2 is also set on the outer wall of the pile body 3 circumference.

[0049] A pair of end plates 4 arranged at both ends of the pile body 3 in the direction of the long axis, the end plates 4 and the steel plate 3 are welded and fixed.

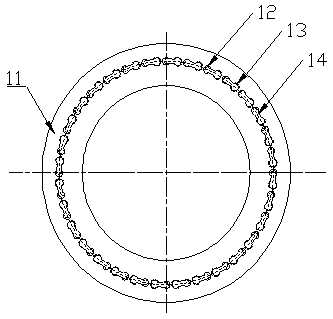

[0050] A reinforcement cage built into the pile body 3, such as Figure 15 As can be seen from the schematic diagram shown, the steel cage is composed of several prestressed steel bars 1 extending in the axial direction of the pile and distributed in a ring and annular stirrups 5 welded on the outer periphery of the prestressed steel bars 1. The prestressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com