Paper flattening device

A paper and paper roll technology, applied in the field of calendering equipment, can solve the problems of inability to achieve rolling effect, difficulty in large-scale application, high equipment cost, etc., to avoid excessive temperature, good rolling effect, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further detailed explanation through specific implementation mode below:

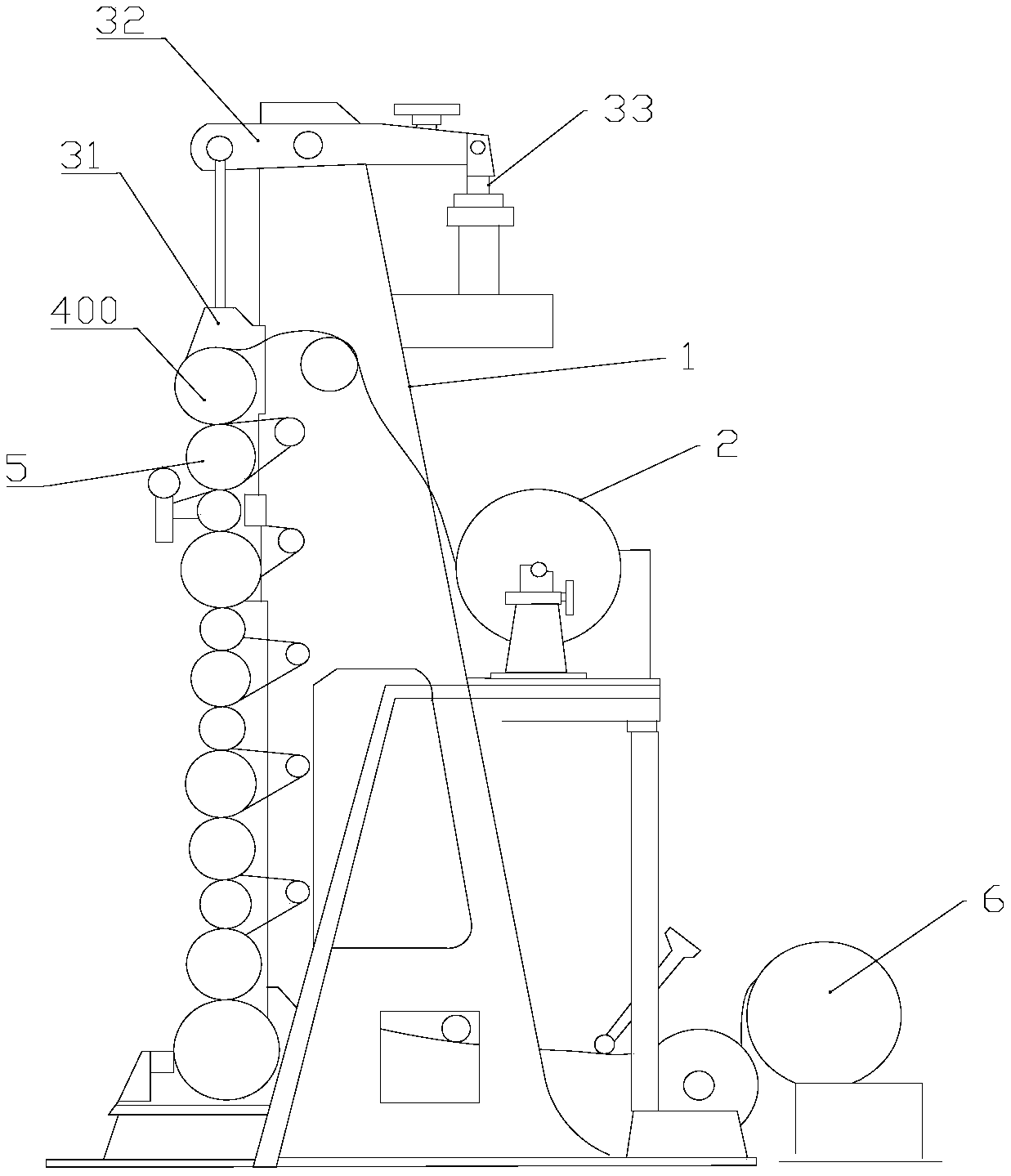

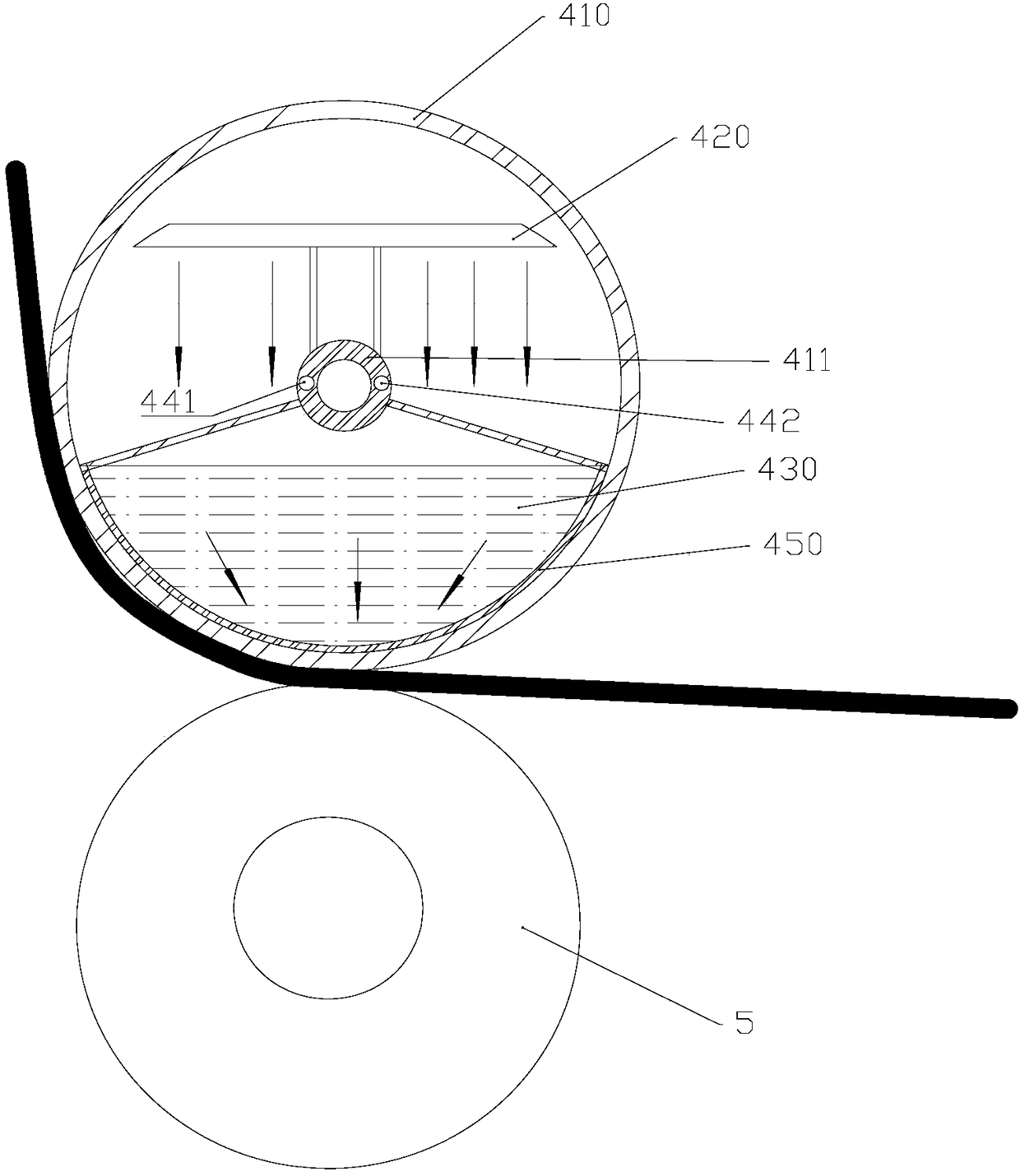

[0021] The reference signs in the drawings of the description include: frame 1, paper unwinding roller 2, lifting frame 31, lifting lever 32, driving cylinder 33, hot pressing upper roller 400, roller 410, annular support plate 411, heating flat spotlight 420 , refraction fluid 430 , air outlet 441 , liquid filling port 442 , protruding part 450 , pressure lower roller 5 , paper take-up roller 6 .

[0022] The embodiment is basically as attached figure 1 Shown: Paper flattening device, including frame 1, paper unwinding roller 2 for winding paper to be flattened, pressurized lower roller 5, hot-pressed upper roller 400, pressurized lift for adjusting the pressure of pressurized lower roller 5 Mechanism and take-up reel 6.

[0023] Frame 1 supports the overall structure, paper roll roller 2 places unrolled paper, pressure lower roller 5 cooperates with hot pressing upper roller 400 to roll the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com