Displacement liquid for deep water drilling liquid

A deep-water drilling and replacement fluid technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of pollution, waste, easy mixing of synthetic-based drilling fluid and water-based drilling fluid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the gelling agent is not particularly limited in the present invention, and it can be prepared by conventional combined preparation methods well known to those skilled in the art. In the present invention, the sources of the polyvinyl alcohol, corn starch, xanthan gum and guar gum are not particularly limited, and commercially available products well known to those skilled in the art can be used.

[0025] Taking the mass of the water phase as 100 parts by weight, the replacement fluid for deep-water drilling fluid in the present invention preferably includes 2 parts by weight of a crosslinking agent. In the present invention, the crosslinking agent preferably includes 20-40 parts by weight of boric acid and 40-60 parts by weight of sodium tetraborate, more preferably includes 30 parts by weight of boric acid and 50-60 parts by weight parts of sodium tetraborate. In the present invention, a cross-linking agent is added to obtain a whole-flowing...

Embodiment 1

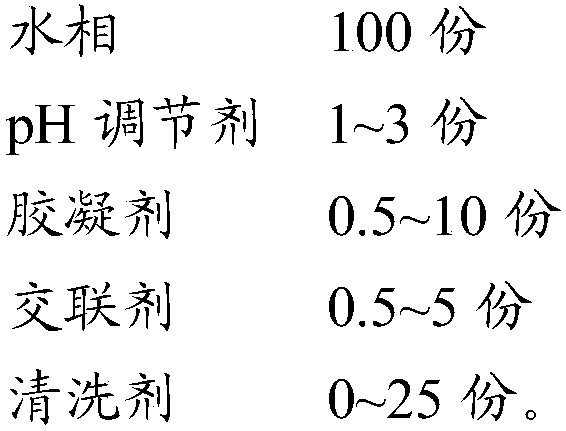

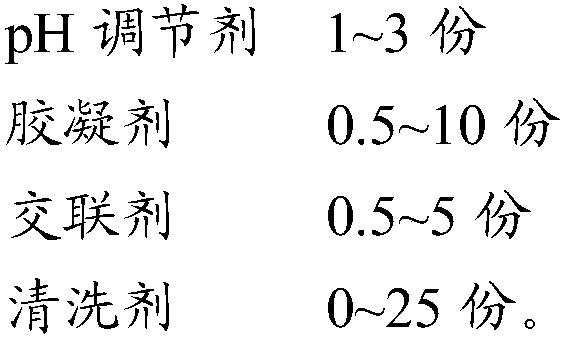

[0034] A replacement fluid for deepwater drilling fluids includes the following components in parts by weight: 100 parts of water phase, 1 part of pH regulator, 0.5 part of gelling agent, 0.5 part of crosslinking agent, 0 part of cleaning agent, and a density of 1.02 g / cm 3 . The water phase is seawater; the pH regulator is compounded by 40 parts of sodium carbonate and 60 parts of sodium bicarbonate; the gelling agent is 40 parts of polyvinyl alcohol, 50 parts of corn starch, 10 parts of xanthan gum, and 10 parts of guar It is compounded with bean gum; based on the boric acid in the cross-linking agent, the cross-linking agent is a compound of 40 parts of boric acid and 60 parts of sodium tetraborate.

[0035] A method for preparing a replacement fluid for deepwater drilling fluid, comprising the following steps:

[0036] 100 parts of seawater, 1 part of pH regulator (obtained by compounding sodium carbonate and sodium bicarbonate with a mass ratio of 40:60), 0.5 part of gel...

Embodiment 2

[0038] A replacement fluid for deepwater drilling fluids includes the following components in parts by weight: 100 parts of water phase, 3 parts of pH regulator, 10 parts of gelling agent, 5 parts of crosslinking agent, 25 parts of cleaning agent, density 1.06g / cm 3. The water phase is fresh water; the pH regulator is compounded by 50 parts of sodium carbonate and 50 parts of sodium bicarbonate; the gelling agent is 40 parts of polyvinyl alcohol, 50 parts of cornstarch, 5 parts of xanthan gum, and 5 parts of guar It is compounded with bean gum; based on boric acid in the cross-linking agent, the cross-linking agent is 20 parts of boric acid and 60 parts of sodium tetraborate; based on perfluorooctyl ammonium oxide in the cleaning agent, cleaning The agent is 5 parts of perfluorooctyl ammonium oxide, 10 parts of isomeric tridecyl alcohol polyoxyethylene ether, 30 parts of fatty alcohol polyoxyethylene ether phosphate, 30 parts of fatty acid polyoxyethylene ester, 30 parts of et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com