Multi-heteroatom codoped hollow porous carbon material, preparation method and application thereof

A porous carbon material and co-doping technology, which is applied in the preparation of nitrogen, carbon preparation/purification, separation methods, etc., can solve the problems of carbon materials without three-element doping, and achieve high surface utilization and good wetting The effect of wetness and developed voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

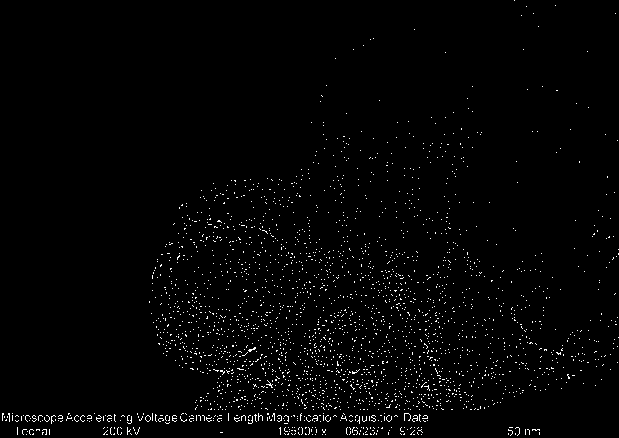

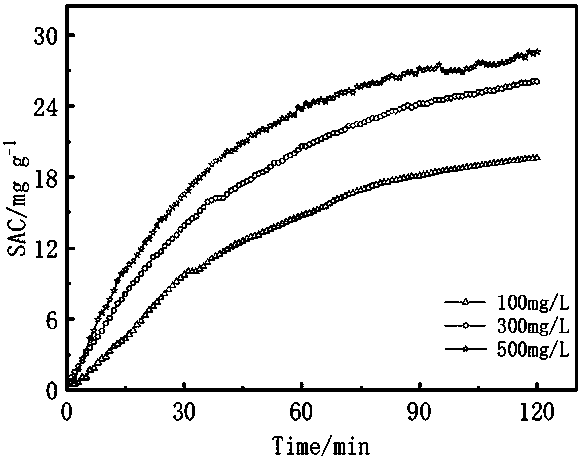

Image

Examples

Embodiment 1

[0030] Dissolve zinc nitrate hexahydrate and 2-methylimidazole with a molar ratio of 1:7 in 100 ml of methanol solution, and mechanically stir for 24 h at a stirring speed of 310 rpm / min to complete the reaction, then centrifuge and wash with methanol solution for 2~ 3 times, dry to get metal organic framework ZIF-8;

[0031] The obtained metal-organic framework ZIF-8 was prepared as a methanol solution with a mass concentration of 0.8wt% ZIF-8, and hexachlorocyclotriphosphazene, 4,4'-sulfonyldiphenol and ZIF-8 were prepared at a molar ratio of 1:3:1. Ratio, at a stirring speed of 310 rpm / min, the methanol solution of hexachlorocyclotriphosphazene and 4,4'-sulfonyldiphenol was added dropwise to the methanol solution of ZIF-8 at a speed of 60mL / min, Add 1 mL of triethylamine dropwise, continue vigorous mechanical stirring for 18 h, centrifuge, wash with methanol 2 to 3 times, dry at 80°C, place in a tube furnace, and control the heating rate under the protection of nitrogen at ...

Embodiment 2

[0034] Dissolve zinc nitrate hexahydrate and 2-methylimidazole with a molar ratio of 1:75 in 200ml of methanol solution, and mechanically stir for 24 hours at a stirring speed of 330rpm / min to complete the reaction, then centrifuge and wash with methanol solution for 2~3 times, drying to obtain the metal-organic framework ZIF-8;

[0035] The obtained metal-organic framework ZIF-8 was prepared into a methanol solution with a mass concentration of 0.9 wt% ZIF-8, and hexachlorocyclotriphosphazene, 4,4'-sulfonyldiphenol and ZIF-8 were prepared at a molar ratio of 1:3:2 Ratio, at a stirring speed of 330 rpm / min, add the methanol solution of hexachlorocyclotriphosphazene and 4,4'-sulfonyldiphenol dropwise to the methanol solution of ZIF-8 at a speed of 60mL / min, Add 1 mL of triethylamine dropwise, continue vigorous mechanical stirring for 18 h, centrifuge, wash with methanol 2 to 3 times, dry at 80°C, place in a tube furnace, and control the heating rate under the protection of nitr...

Embodiment 3

[0038] Dissolve zinc nitrate hexahydrate and 2-methylimidazole with a molar ratio of 1:8 in 160ml of methanol solution, and mechanically stir for 24 hours at a stirring speed of 320rpm / min to complete the reaction, then centrifuge and wash with methanol solution for 2~3 times, drying to obtain the metal-organic framework ZIF-8;

[0039] The obtained metal-organic framework ZIF-8 was prepared as a methanol solution with a mass concentration of 0.86wt% ZIF-8, and hexachlorocyclotriphosphazene, 4,4'-sulfonyldiphenol and ZIF-8 were prepared at a molar ratio of 1:4:3 Ratio, at a stirring speed of 320 rpm / min, the methanol solution of hexachlorocyclotriphosphazene and 4,4'-sulfonyldiphenol was added dropwise to the methanol solution of ZIF-8 at a speed of 60mL / min, Add 1 mL of triethylamine dropwise, continue vigorous mechanical stirring for 18 h, centrifuge, wash with methanol 2 to 3 times, dry at 80°C, place in a tube furnace, and control the heating rate under the protection of n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com